Chandar ... ‘we are content to be in the Gulf’

Chandar ... ‘we are content to be in the Gulf’

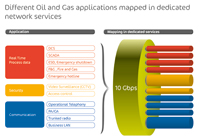

IN ORDER to serve its Gulf-based customers in a better and quicker way, Ventil Test Equipment, one of the world’s leading manufacturers of high pressure test equipment for industrial safety, control and shut off valves, is planning to expand its Middle East operations currently being run through its subsidiary Ventil Middle East, located in Saif Zone, Sharjah, UAE.

The Netherlands-headquartered company is looking at the possibility of stationing a rental fleet of valve test and repair machines and containers in the UAE to facilitate the requirements for overnight solutions. At the same time, it also plans to introduce the Ventil Valve Academy – a training centre in valves and valve repair – into the Gulf region.

“Globally we see a growing awareness that plant safety and efficiency is directly affected by non-performance of valves, either in terms of output or in terms of reliability and availability. Ventil can provide the tools and know-how to maintain and even improve the integrity and performance of valves to assure plant efficiency, reliability and safety,” says Arthur Baars, CEO, Ventil Group.

“There are fewer technical people employed in workshops today and with over 40 years of experience, we can train operators about all the ‘do’s and don’ts’ of valve servicing,” adds Bala Chandar, director Ventil Middle East.

According to Chandar, shut-off, control and safety valves are final process elements and, therefore, play a key role in the operation of the process installation or power plant. They either block the pressure, regulate the fluid or protect the process. “However, still 50 to 60 per cent of the fugitive emission of industrial process installations is caused by leaking valves. Emergency shut-downs, collateral damage and even life threatening situations still occur as a result of improper maintenance and testing of valves,” he adds.

Ventil has a long history in the Gulf. The company is a preferred supplier and over the past 15 to 20 years has delivered several thousand of machines to all major oil and gas companies and valve repairers in the GCC. “The Gulf has always been a very good region for us and we feel at home. To some customers we now deliver the second or even third generation of machines. We are now ‘local’ and our goal is to expand our collaboration with our customers to improve their competence and competitiveness,” says Baars.

Since the opening of Ventil Middle East, the company has seen a growing flow of orders. Besides the GCC states, it now receives a good number of orders from Iraq as well.

“We are very content to be in the Gulf. Being where the customers are enables us to produce what the customer needs, wherever they need it, with local support,” Chandar adds.

Ventil caters to two different customers: valve manufacturers and valve repairers. Baars says both markets keep it busy and in fact over the past years it has seen an annual growth of 25 to 30 per cent.

“However, by opening overseas subsidiaries and developing a lot of new products and services, we have been able to achieve sustainable growth. This is valuable to us,” he adds.

To cope with the growing demand, Ventil has even expanded its production facility in Rijswijk, The Netherlands with an additional 1500 sq m to a total of 4,200 sq m.

According to Baars, Ventil is constantly developing new products and solutions. “`Ventil, the Innovators in Valve Testing’ – this isn’t an empty slogan,” says Baars.

“Each customer and especially valve manufacturers, have different needs. The latest product is the Ventil VenTrack a portable, diagnostic test system for control valves. The VenTrack helps the control valve repairer to go further and beyond the general valve rebuilding process which is commonly based on the valve’s external appearances,” he adds.

“Approximately 30 per cent of our business is specials and this means there always is something special going around. For example, right now we are building a 3,000 tonne test unit for Class 4500 Axial Check valves, a 1000 tonne test unit for butterfly valves up to 80-inch and a Cryogenic test unit for Control valves up to 24-inch,” says Chandar.

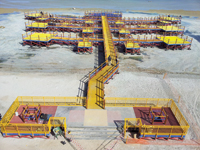

Speaking of another trend, Chandar says that containerised workshops are the latest in the valve repair business. “Plant owners want to keep track of their valves, but are also looking for solutions to reduce down time. Our fully equipped 10 or 20 ft on or offshore containers enable valve repairers to do almost everything on-site,” he adds.

Looking forward, Baars says: “Obviously the oil and gas industry is dealing with some of the greatest challenges it has encountered in several generations. Safety, liability, but also ‘Greening’ and environmental sustainability call for new solutions. Challenging times, but we see emerging opportunities. Our products can help the industry to be competitive and answer to the growing demand and tougher conditions.”

Besides representatives in all industrial areas, Ventil is located in Rijswijk – The Netherlands, Houston, Moscow and now also in Sharjah – UAE. Ventil employs 80 people (FTE).