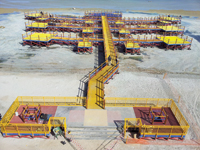

Intergraph’s 3D model

Intergraph’s 3D model

TO MANAGE the challenges of increasingly complex plant operations and projects, the world’s top oil and gas industry leaders are continually seeking ways to increase productivity and accelerate project schedules while maintaining safety standards and high quality. Intergraph’s software for the design, construction, operation and management of plants and other facilities provides efficiency increases of up to 30 per cent in the generation and management of engineering data, says a company spokesperson.

Historically, companies around the world had to make considerable initial and on-going investments to develop applications and integrate them with commercial solutions. With a new generation of integrated software solutions on the market, owners and operators of onshore and marine plants can improve productivity and save costs by producing high-quality deliverables in less time. Data-centric, rules-based 3D technology enables better user productivity, improved collaboration and higher quality engineering deliverables than previously available.

Intergraph spent the last 10 years developing and bringing to market a set of integrated applications that deliver and define the engineering, construction and fabrication enterprises. SmartPlant Enterprise (SPE) gives clients the largest set of market-leading applications, starting from the schematic design of an asset through to physical modelling, materials management, construction management, fabrication automation and information management.

Behind the scenes at Saudi Aramco and its joint ventures: Saudi Aramco Total Refining and Petrochemical Company (Satorp) adopted Intergraph SmartPlant Instrumentation (SPI) as their Central Shared Instrumentation Database (CSIDB) to specify, record and control all different variables, such as flow, temperature, level or pressure.

The challenge of building a world-class refinery such as the Jubail Refinery (400,000 barrels per day) is simplified by coordinating and synchronising the instrumentation engineering deliverables generated by nine different contractors. The scope of data collection and information sharing was colossal and called for an instrumentation solution which could address all different aspects of instrumentation design and specifications in one application and could integrate well with other solutions.

SPI enables all engineering, procurements and construction contractors (EPCCs) working on the project to create and manage Satorp instrumentation documents/drawings. The system includes integrated modules for instrument indexes, datasheets, process data, preliminary instrument calculation, wiring, loop drawings, hook-ups, calibration and maintenance. In addition, the piping and instrumentation diagram (P&ID) – the “roadmap” of the plant – will be developed and managed by SmartPlant P&ID.

Saudi Aramco Mobil refinery is using Intergraph SmartPlant Foundation to leverage the engineering design basis across the complete plant life cycle.

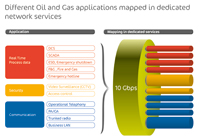

One step ahead: Facilities and requirements change every day and engineering configuration management systems have to keep up to speed. Intergraph market-leading, next-generation plant, design and material handling tools, provide customers with solutions to reduce costs, and increase efficiency and security.

This year, Intergraph has launched additional solutions to leverage existing plant engineering information and Intergraph online cloud computing environment, so customers can access Intergraph solutions from the internet at any time, from any location. Intergraph’s newest solution SmartPlant Fusion specifically tackles the challenges faced by plant operators and engineering, procurement and construction (EPC) companies in accessing, organising and managing unstructured legacy engineering information of an operating plant.

SmartPlant Fusion “crawls” through all these information formats and locations, automatically reads and extracts meaningful content and assembles a highly organised plant record that can be simply navigated via an intuitive photo-realistic web portal.

Oil and gas companies of all sizes face growing challenges to remain competitive and profitable, and need every advantage possible to stay one step ahead. Interoperability and data-centric, rule-based technology can offer intelligent answers to these challenges – in today’s and tomorrow’s market.