ESTABLISHED in Saudi Arabia since the early 1980’s, Hajjan Trading and Industrial Services Company Ltd (Hatcon) partners with some of the world’s leading suppliers to provide its clients with the highest quality products and solutions, delivering the performance they demand every time. Its scope spans a wide spectrum of activities ranging from sales and servicing of high performance protective coatings and linings, architectural products, industrial cleaning equipment, airless paint spray equipment to advanced surface preparation abrasives.

Its regional offices are spread over key industrial zones throughout the kingdom, and a dedicated staff provides 24 by 7 support. Hatcon services many key industries, including oil and gas; petrochemicals; mining; transport; water supply; marine; infrastructure and others. The company’s facility in the Eastern Region is spread across 6,000 sq m in Jubail and has its headquarters in Al Khobar. Hatcon also maintains full fledged branch offices in Riyadh, Jeddah and Yanbu. Outside the kingdom, Hatcon has offices in Bahrain and Lebanon.

The services offered by Hatcon include: refurbishment of rotating equipment like centrifugal pumps, vacuum pumps and compressors; refurbishment of stationary equipment such as valves and heat exchangers; internal and external coating protection of steel tanks and process vessels; leak repairs of water and hydrocarbon pipe lines; internal and external coating protection of pipes, spools and fittings; repair and fabrication of RTR pipes, tanks and other polymer based composites and coating and lining of concrete chemical containment systems.

|

Hatcon has extended its product line to |

Hatcon’s, one of the major achievements during the past year was the certification of its Quality Management System to the ISO 9001:2008 standard. “Our aim for continual improvement, adoption of tested problem solving methodologies and quality improvement tools has largely helped us meet and exceed our customers’ expectations. These coupled with the involvement of our staff in the formation of quality circles has largely contributed to the improvement of our operational capabilities”, says Bobby Satheesh, management representative.

“What has enhanced our customer satisfaction index is the opening of our state-of-the-art training facility which covers customised technical and practical coating application programmes. These programmes, which are designed and delivered by our experienced crew, have found excellent feedback from our esteemed customers,” he adds.

In addition to the above, Hatcon has extended its product line to include modified novolac epoxy polymeric systems manufactured in Canada by Speciality Polymer Coatings especially designed for coating of pipe spools. Moreover, Hatcon has set up a joint venture with Thejo of India for the local provision of a comprehensive array of products and services: rubber splicing, pulley lagging and rubber sheeting.

According to Satheesh, the demand for sustainable energy has been the drive behind the influx of a number of projects. The higher awareness among projects for minimal down time and improved efficiency will surely raise the bar for higher performance coatings along with all associated services. The above factors will help to filter and shape the quality of service to be provided on the market.

Buoyed by an increase in demand for its products, Hatcon plans to create a pipeline coating department and initiate the full launch of its training school in the current year.

“Due to the high brand awareness we had created for our product line solutions and the discerning clientele we maintain, demand has increased considerably requiring us to integrate our activities much more into operational matters, QA/QC & Safety,” says Satheesh.

Additionally, the company is also looking at integrating its safety management system (SMS) with its quality management system (QMS). It hopes to record considerable growth over the next year and this is due to the economic growth the kingdom is currently witnessing.

The company believes that the investment in human resources is the key to any success. “This creates higher company loyalty which trickles down to improved performance at all levels,” says Satheesh. Coupled with the economic growth the kingdom is witnessing, this is surely a formula for success. “Hurdles and constraints are something we encounter daily. However, the resilience and drive behind a motivated team will surely be the drive for continual success,” he adds.

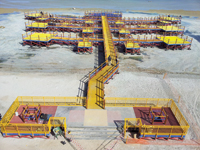

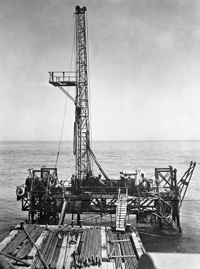

Some of the major projects it has worked on include the Yanbu Export Refinery, Wasit Gas Project, Saudi Aramco Khursaniyah project and Karan Gas project.