GERMAN major Stahl CraneSystems (SCS), one of the leading brands and the largest manufacturer of explosion-protected hoists and crane components, expects continuous healthy growth for its Saudi Arabian operations in the next three years.

Stahl CraneSystems, which has formed a joint venture with Eastern Morris Cranes Company (EMC) in Saudi Arabia, is offering more than 5,000 sq m manufacturing space and a combination of great service and quality products from its offices located in Dammam, Riyadh, Jubail and Jeddah in Saudi Arabia; Bahrain and Qatar across the GCC market.

EMC was established in 2000 in Dammam Industrial City, Saudi Arabia. EMC has been producing top quality lifting equipment for the last decade, under a strict quality control, and continuous research.

“SCS in the past year has seen continuous organic growth and we expect healthy, stable, sustainable growth for this as well as for the next three years,” says Jens Wesseler, business development manager, SCS.

The company’s product range extends from lifting equipment, electrical overhead, gantry and jib cranes, wire rope hoists, chain hoists to overhead cranes with 160 tonne safe working load (SWL). It is also one of the leading global suppliers of off standard hoists, wire rope hoists, winches for gas and dust environments, drive and control technology and condition monitoring systems.

In addition to the range of products, it also provides training, service and maintenance of the lifting equipment. “We provide after sales services with long term contracts to the biggest oil and gas company in the region – Saudi Aramco, and its various facilities spread across the kingdom at Petro Rabigh, Sipchem and Oman LNG,” adds Abood Ali Humaid, general manager, EMC.

SCS and EMC also offer wide-ranging services from consulting to engineering to gaining approvals and certification for its products or for a dedicated oil and gas company especially for older equipment in hazardous areas.

|

SCS and EMC offer wide-ranging |

“SCS has already implemented all new international standards and norms. All products are certified according to the latest statutory requirements,” says Wesseler. The company has recently launched a new open winch design and established the new twin hoist concept successfully into the market.

During 2012, SCS was awarded more than 150 different types of lifting equipment orders by various contractors around the world including Fluor, Daelim, GS Engineering, Jacobs, Tecnicas Reunidas, J Ray McDermott and others. “A big share of orders is, of course, coming from Sadara petrochemical complex, ABS and IPC EVA project. Further, numerous amount of equipment orders have been awarded directly by Aramco or via local engineering companies,” says Humaid.

The challenge of the projects was to match the specification to the satisfaction in quality and product parameters of the client and develop together with the EPC the most economic way to fulfill the high standard, adds Wesseler.

Some of the other big orders, SCS has completed in the last year include: 17 cranes for Zamil Offshore for the new ship yard project in Dammam Port and two Goliath cranes for Al Yammama Contracting for 175 tonne and 80 tonne. The contract for 17 cranes was awarded to SCS by SSP a major sub-supplier of Aramco for their next expansion which is supposed to be ready by mid of 2013.

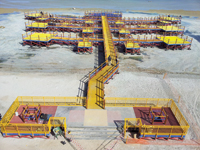

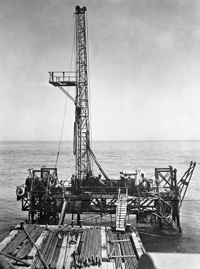

SCS has also successfully completed two projects for Saudi Aramco’s offshore facilities where the environment and safety requirements are very challenging compared to other sectors. The projects have been awarded to SCS by J Ray McDermott as well as Technip.

“In 2013, the Jizan economic city, especially the Jizan Refinery will be very interesting and challenging for us,” says Abood, and adds: “At present we are preparing to open our branch office in Jizan. It is our aim and philosophy not to let any customer down irrespective of his location in the kingdom. Hence it was a quick decision to have our presence even in this very remote area.”