Amco Weir ... an eminent vendor in the oil and gas industry

Amco Weir ... an eminent vendor in the oil and gas industry

WEIR Arabian Metals Company (Amco Weir) is an engineering and general machining subsidiary of the Saudi-based Olayan Group and UK based Weir Group. The company is a key service provider to the oil field industry.

Before the joint venture (JV) was formed in 2005, Arabian Metals Company (Amco) established an astonishing 28 years of professional experience in the oil and gas industry primarily to serve the oil field industry in the eastern region of Saudi Arabia from its Dammam base.

The company provided engineering and general machining services to oil field operators and service companies, specialising in the repair and re-certification of drilling components.

The JV was formed in order to strengthen the local manufacturing capabilities in the kingdom and bring world class technology to the country and it has been very successful. Weir brings over 140 years of international industrial engineering experience and proven methodology to the JV.

The company has an excellent reputation for quality and service: Amco Weir is available 24 hours a day, seven days a week, and 365 days a year; and is a preeminent vendor and service support organisation for the oil and gas industry.

The company’s main client, in terms of oil production and oil field operation, is Saudi Aramco, with which it has an ongoing service contract. Amco Weir also counts the leading oil field services companies such as Halliburton, Schlumberger and Baker Hughes, as well as drilling companies, including Nabors, Arabian Drilling Company (ADC), Saipem and Transocean – among its customers. In addition, Amco Weir works for SEC (Saudi Electricity Company) and Sabic, too. Amco Weir has invested heavily in machine tooling to support the requirements and demands of its customers.

Amco Weir is structured into four core product and service segments.

Tubular equipment and accessories; valve, BOP and wellhead recertification: The tubular segment includes the inspection, repair and recertification of drill pipes, tubing, crossover subs and everything else that goes into a well.

Within this segment, Amco Weir has licence agreements with several international companies, such as Vallourec, Hunting, Nippon Steel, Tenaris Hydril and Grant Prideco, for the repair of premium connections.

These are specific and special threads that are machined onto the tubing, and Amco Weir are licensed to perform the recut and re-certification of these parts, so that they can go back into the field as soon as possible.

Amco Weir also manufactures the accessories crossovers and pup joints locally in Saudi to API standards 5CT, 5 DP and 7-1.

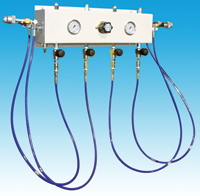

Repair and API accessories manufacturing: The valve and wellhead segment incorporates re-certifications of BOPs and they are authorised to repair pressure control equipment for GE, Hydril and NOV Shaffer. Additionally Amco Weir repair, certify and manufacture flow and pressure control manifolds to API 16C specification. They also repair, re-certify and manufacture API 6A wellhead and Christmas tree equipment.

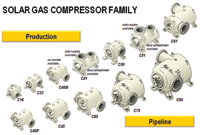

Rotating equipment: The rotating equipment segment is a division that has been added into the overall services that they provide. It involves anything that has to do with the repair, maintenance and upgrading of rotating equipment, be it centrifugal pumps or compressors, steam turbines, blowers or gearboxes. In the case of centrifugal pumps, Weir is well-known around the world for being one of the leading designers and manufacturers of rotating machinery.

Spare parts manufacturing: Amco Weir gets involved in supplying customers with manufactured spare parts that are re-designed, and also re-engineers existing equipment.

The company is not only capable of manufacturing parts with a high degree of precision, but can also repair and fabricate components weighing up to 15 tonnes, thanks to its state-of-the-art facilities. As part of its long-term strategy to achieve growth and diversification, the company has recently more than doubled its size, and now operates from two adjacent sites with a combined area of 35,000 sq m.

Amco Weir has the tooling resources for the products that they produce; testing facilities, with tests up to 30,000 psi; cladding and welding facilities, which allow them to perform re-certification, repair and maintenance of components.

Amco Weir employs over 220 people and runs 24/7. The skills range from machinists and quality control managers to technical inspectors and engineers.

They have an engineering department for both the oil field and the rotating equipment sectors, and this is staffed by mechanical engineers, who provide expert assistance in the development of designs and specific procedures for repairs and manufacturing.

Essentially, Amco Weir is a service company, and carries out its business in a very dynamic, day-to-day basis, rather than a project basis.

Response, response, response is Amco Weir’s mantra as the customer does not need things done today, they need them done yesterday.

Sometimes, a customer will send a part in a truck, which will wait while it is repaired or a spare part is manufactured then it will take the part straight back to the customer’s rig.

Recently, Amco Weir has been awarded to re-rate and overhaul two API 610 BB1 crude oil transfer pumps. The pumps will be used to feed a new 400,000 barrels per day (bpd) capacity refinery (Yasref).

The pumps are located in the Western region of Saudi Arabia in Yanbu industrial complex. The scope of work includes hydraulic review, re-rating of the pumps to increase flow levels and upgrades with an API 682 cartridge type mechanical seal to increase pumps reliability.

This solution from Weir oil and gas services allows Yasref to significantly reduce the cost of new installations and reduces lead times when compared to purchasing new equipment.

.jpg)