MARAFIQ, Saudi Arabia’s leading water and electricity services operator, has contracted Veolia Water to design, build and operate the largest ultrafiltration and reverse osmosis desalination plant in Saudi Arabia.

With this contract, Veolia Water will generate $310 million in revenue for the plant’s design and construction, and $92 million in revenue for its operation for 10 years, with an option to extend the contract for a further 20 years.

With a capacity of 178,000 cu m per day, this new plant will supply the Sadara petrochemical complex built by Dow Chemical and Saudi Aramco in Jubail Industrial City II and is due to come on stream in June 2015.

Dow Chemical and Aramco will produce solvents and glues for the automotive and packaging industries at the Sadara site. The water supplied will be used in this immense facility’s two cooling towers and as boiler feed water.

To meet the very strict water quality standards required by Marafiq and minimise this new plant’s impact on the environment, Veolia Water, through its subsidiary Sidem, has designed a plant combining two seawater treatment solutions: ultrafiltration and reverse osmosis.

After an initial treatment phase involving dissolved air flotation to capture the suspended particles in the water and ultrafiltration, the water will then be desalinated by reverse osmosis membranes before being remineralised.

The combination of these various processes will ensure a secure water supply, limit the risk of plant failure and extend its lifespan, while at the same time reducing the site’s energy requirements and costs.

Created in the 1970s by the authorities of the Kingdom of Saudi Arabia, Marafiq operates the country’s water and electricity services and is responsible for overseeing the development of the Jubail and Yanbu industrial cities designed to ensure Saudi Arabia’s economic diversification.

“With this new reference, Veolia Water confirms its position as a leader in desalination and the reference partner for industrial entities. Veolia Water’s unique expertise and technology were the deciding factors in meeting the requirements of these exacting clients Marafiq, Saudi Aramco and Dow Chemical,” explains Jean-Michel Herrewyn, chief executive officer of Veolia Water.

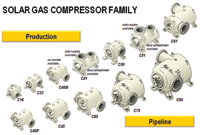

Present in Saudi Arabia since 1979 where it built the desalination plant for the city of Al Khobar in the Eastern Province, near the Gulf, in 2010, Sidem had already built the first desalination plant in Jubail City.

One of the largest and most efficient in the world, this 800,000 m3 per day capacity plant uses Veolia’s multiple-effect distillation (MED) process, which consumes three times less energy than rival processes.

.jpg)