TO PLAN and build an entirely new district cooling plant in an environment friendly, energy efficient and safe manner in the midst of a bustling community presents huge challenges.

Saudi Aramco’s Dhahran District Cooling project has achieved even more than this. Not only has it ticked all the boxes for the above, it stands as the first project of its kind undertaken in Saudi Aramco.

The pilot Dhahran District Cooling Plant project that recently came online is a centralised plant that replaces 11 existing central air conditioning plants to service the Saudi Aramco headquarters’ Core Area, community centres and other Saudi Aramco medical and industrial facilities.

Initiated by Community Services and Business Development, it is the culmination of an unprecedented collaboration between a myriad of company departments and contractors. It involved demanding schedules and a considerable measure of expertise and innovation.

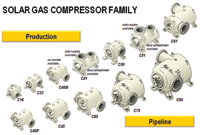

On May 3, 2010, Community Services signed a 25-year contract for the Dhahran Area District Cooling Plant with a national company on a Build, Own and Operate arrangement to construct a 27,000 refrigerant tonne central cooling plant with an associated 30 km chilled water underground piping network, 11 energy transfer stations and a 35 MW power system.

The new district cooling plant is essentially a commercially viable enterprise and it is expected that it will provide the impetus for the construction of similar operations Saudi Aramco wide.

During the period of construction, Community Services Project Support Department, headed by Mohammad Al-Houraib, was responsible for the project management and coordination of activities alongside other Saudi Aramco departments and outside agencies.

Major cooling plant equipment includes eight 2,500-tonne capacity chillers and one 7,000- tonne capacity thermal chilled water storage tank providing a total peak capacity of 27,000 tonnes of chilled water. If required, there is a provision at the plant to increase capacity by 5,000 tonnes.

Al Houraib praised a faultless safety record during the project, which chalked up a massive 3.2 million safe man-hours.

“That safety record is actually quite astounding when you consider the many unforeseen underground utilities that were encountered during excavations for the installation of chilled water piping where trenches were as large as six metres wide by six metres deep,” Al Houraib says.

The process caused some inconvenience to the Dhahran community in the form of excavations crisscrossing roads. But the benefits are many; the new plant will reduce electricity consumption, reduce environmental emissions, air pollution, greenhouse gas and ozone-damaging refrigerant.

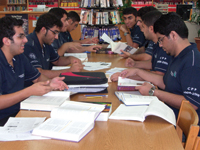

For those involved, the Dhahran District Cooling project has been a steep learning curve, and has given young engineers unique exposure of a from-scratch-to-completion project and all the complex processes that are involved.

A priority was also being in line with one of Saudi Aramco’s core values, safety and maintaining safe sites 24/7 while minimising disruption to the Dhahran community.

For Hussein Al Hammad, Community Services Project Support for District Cooling, the endeavour stands out because of the empowerment and success of its team of young engineers.

It is no small feat that a team, containing five project engineers in their 20s, steered a complex and challenging scheme to a successful conclusion.

“In Saudi Aramco, there are always areas for improvement and another point for me is that this company encourages people to find ways to excel, exercise responsibility and meet challenges,” Al Hammad says.

“For this young generation, we encourage them and give them authority and they meet expectations.”

The Dhahran District Cooling project has a bigger significance though. It will stand as a model for Saudi Aramco and will be a commercial success due to the contract’s build, own and operate nature. Saudi Tabreed will oversee the day-to-day running of the facility.

The project is also committed to the development of a local workforce with an initial 40 per cent of employees currently Saudi, rising to 100 per cent in five years’ time.

In terms of environment and cutting emissions, the project is a model of best practice. In the medium-to long-term, it’s about grafting the model Saudi Aramco wide, taking a major step on the right environmental path and assuming the lead in the industry.

Electricity consumption will be reduced as will environmentally-harmful emissions traditionally associated with refrigerant. From erecting power lines, to managing excavation sites safely in the community, to coordinating with a myriad of Saudi Aramco organisations and outside contractors, the team, mentored by management, has excelled, added value and experience to the company.

The Dhahran District Cooling project stands as an example, not just within the company, but within the wider kingdom and beyond, for excellence.

.jpg)