Fateel ... hoping for a good year

Fateel ... hoping for a good year

IN A bid to serve the oil and gas market dedicatedly, Alteem, one of the leading firms in the field of electromechanical works, is readying to enter the Saudi Arabian and Oman markets next year.

The Bahrain-based company established in 2006, is in the process of opening its office in the Sultanate of Oman, which will start operating in 2014, says Husain Fateel, general manager, Alteem.

Alteem, whose vision is to be the clients’ first choice for electromechanical solutions and specialised electro mechanical requirements in the oil and energy sector across Bahrain and the entire region, says precision of design, managing and executing projects efficiently and professionally, as well as adherence with work schedules, are the most prominent features of its deep-rooted business policy.

Alteem says it is dedicated to the delivery of electromechanical solutions to its clients in partnership with its partners and consultants. “We have achieved our goals by providing engineered solutions and adhering to the highest standards of safety, quality and environmentally centric practices while completing our projects on time and within budget. Our success stems from our policies to continuously invest in technological capabilities and innovation to ensure market adaptability,” he adds.

Alteem has an impressive record of undertaking major industrial and electromechanical contracts in Bahrain. The company is managed by a team of professionals in different disciplines and has the distinction of completing prestigious projects for works at Alstom, Ariva, Bapco, Sukoon Tower Project, Ministry of Education, Electricity and Water Authority (EWA), Bahrain Stadium, Tashyeed Properties and some other municipalities and several large commercial and residential complexes on the island.

|

|

Alteem ... dedicated to the delivery of |

“Our clients look to us for innovative solutions, expecting attention to detail and awareness of leading edge technology. Our team of experienced project managers, engineers and technicians emphasise cost effectiveness, quality and functionality in mechanical, electrical and oil and gas services,” says Fateel.

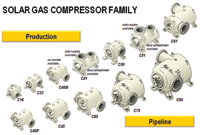

Alteem is specialised in the following areas: Power and energy services; oil and gas services; non-man entry storage tank cleaning; studies and analysis; iron art works and fabrication and steel works.

Alteem has completed several projects in the power and energy sector along with Ariva and Alstom in Bahrain such as erection and maintenance of power stations and sub-stations all over the island.

In addition, Alteem is an agent to Arkoil Technologies which is one of the largest professional oil service company, which developed and internationally provides exclusive and unique systems to clean tanks contaminated by oily sludge (be it crude oil, black products, petrol or similar) as well as renovating heavily oil-contaminated land plots.

“Arkoil Technologies is focused on providing the best results for its clients, wherever in the world. We achieve this by paying close attention to clients’ needs, responding with current experience and resources within the company. Our main goal is to deliver efficient solutions that exceed expectation and requirements settled by local governments and Super Mayors.

“For many years of professional application of technologies within different challenging regions worldwide we did not abandon even a single project due its technical complexity, deadlines or weather conditions,” Fateel says.

Recently, Arkoil Technologies has completed a large tank (non-man entry) cleaning project for Zeeland Refinery at the Netherland which is owned by Total and Lukoil. The project was successfully completed with high level of proficiency and effectiveness which reaches a high level of customer satisfaction.

According to the Contract ZR-C-2O12 Arkoil Technologies Nederland performed cleaning of the crude tank 030ML03 (storage capacity – 80,000 cubic metres, diameter -72.5 m) at the tank farm of Zeeland Refinery, Nieuwdorp, The Netherlands.

According to the initial measurements volume of the accumulated oil sludge was 2,000 cubic metres. Upon application of Arkoil’s non-man entry crude tank cleaning system the accumulated sludge was separated into three fractions: hydrocarbons, water and solid sediments.

Hydrocarbons, free from any sediments or impurities, were successfully recovered by Arkoil’s engineers and were further processed by the refinery. This recovery allowed to meet the main goal of the contract and more than 95 per cent of oil was recovered. Water was drained and treated internally. Sediments were removed from the tank and brought to place specified by the customer. The tank was prepared to hot works.

Alteem is also working closely with some regional oil and gas organisations to implement Arkoil’s non-man entry tank cleaning system which showed its efficiency, safety and environmental friendly. The technology and services was presented to the Bahrain Petroleum Company (Bapco) engineering team who has shown their interest in using the same on the earliest.

In addition, Alteem is working closely with Alstom to get a huge contract in building a new power plant in Bahrain for the EWA.

The company’s business like many other in the Kingdom has not looked up in the past year due to the economic slump.

“Business in the last year was not really good as we wanted to be and that was due to the regional economic crisis that hit us,” admits Fateel.

“This year business, so far, is unstable and unsteady. I hope this situation doesn’t last for long till the end of the year and we expect a better business for the next year,” a hopeful Fateel adds.

Meanwhile, Alteem has signed an agency agreement with ICO, an Italian company which manufactures a wide range of tools and equipment for the building and maintenance of ships, shipyard, above ground storage tanks and for surface preparation and maintenance.

.jpg)