Haradh ... upgradation with GE advanced technology

Haradh ... upgradation with GE advanced technology

GE HAS replaced an aging compressor control system at Saudi Aramco’s Haradh gas/oil separation plant in Saudi Arabia’s Eastern Province with advanced technology that automates the control process for three compressors and will improve performance and production.

The new system was commissioned earlier this year and is operating successfully at the plant. This marks the first compressor control project with Saudi Aramco for GE’s Measurement & Control business, building upon GE’s past experience of providing turbine and generator controls for the company.

Haradh GOSP-1 is a critical plant for Saudi Aramco, and its three motor-driven compressors play a vital role by maintaining the compression of the gas after it is separated from the oil.

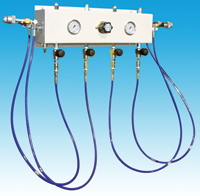

The previous compressor control system used programmable logical controllers, which GE replaced with Mark VIe technology, along with GE’s OptiComp compressor control algorithms and remote control capability from the plant’s existing distributed control system.

“As the world leader in the production of petroleum-based energy, we at Saudi Aramco hold ourselves to the highest standards of excellence and have very specific requirements when it comes to compressor control and protection,” says Ahmad Saleh Haradh, GOSP1 Saudi Aramco project engineer.

“From the start, GE worked closely with us to understand our unique needs and specifications and remained flexible throughout the entire project. The updated control system is now in full operation and is satisfying all of our performance expectations.”

“Saudi Aramco is a key partner of GE, and we demonstrated to them our ability to meet their specific programme requirements through extensive demonstrations and testing of our solution from the very beginning. Robust planning and our close partnership with the Saudi Aramco team led to the smooth installation of a highly customised control package within a short timeframe. This project adds to our proven experiences and successes in the region where we have over 80 years of presence and a strong understanding of local industry needs,” says Rami Qasem, president and CEO, GE Oil & Gas, Middle East, North Africa and Turkey.

The solution features GE’s Mark Vle control platform with OptiComp control software and provides capabilities such as anti-surge, motor limit, pressure control, discharge pressure and pressure override control.

GE also saved significant plant space by building a single platform to control all three compressors (two high-pressure compressors running in parallel and one low-pressure compressor running in series).

Additionally, GE performed surge tests on all units to help ensure optimal compressor performance.

These tests enabled GE to enhance the performance of the low-pressure compressor and reduce degradation, ultimately expanded the operating envelope for that compressor.

.jpg)