ABB, the leading power and automation technology group, has won a project from Foster Wheeler for the automation of bulk inventory operations management of the chemical complex that is under construction by Sadara Chemical Company in Jubail Industrial City II, Saudi Arabia. The order was booked in the first quarter of 2013.

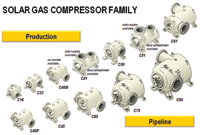

Under the scope of this contract, ABB will design and execute the automation of the tank farms and portions of the packaging centre that will include the transport of bulk raw materials and finished products to and from the complex and internally between production units, through pipes, trucks or trains.

ABB’s T-MAC Plus system will be deployed to optimise the operation and will increase energy efficiency, safety and control, with a scalable solution that is compatible with the management systems of most of today’s industries.

Innovative automation technologies from ABB, combined with our industry knowledge and experience, will provide the Sadara project with the solutions and support it needs to significantly increase productivity, energy efficiency and process reliability, says Veli-Matti Reinikkala, head of ABB’s Process Automation division. We will help ensure that the Sadara chemical complex will be highly efficient and one of the most productive of its kind.

ABB has worked on the Sadara project since October 2011, when it was selected as the Main Automation Contractor (MAC). The scope of supply included process automation systems, safety systems and related services, such as project management, project engineering and other site support activities. The project is currently under construction and is one of the biggest projects ABB will have ever executed when complete.

Established in October 2011, Sadara is a joint venture developed by Saudi Arabian Oil Company (Saudi Aramco) and The Dow Chemical Company (Dow).

With a total investment of approximately $20 billion, the Sadara complex will be one of the world’s largest integrated chemical facilities, and the largest ever built in a single phase.

First products are expected to come on line in the second half of 2015, with all production units coming on line by the end of 2016.

.jpg)