PFST products ... High pressure turbine meter, HVT-FV Venturi meter and Wedge-type meter

PFST products ... High pressure turbine meter, HVT-FV Venturi meter and Wedge-type meter

PFS Technologies (PFST), a global provider of field-proven solutions for oil and gas, refining, distribution, petrochemical, power, steel, and water applications, offers products including flow meters and monitors, as well as advanced compressed air foam (ACAF) fire suppression solutions.

Having served major producers in the Middle East for decades, the company recently established an office in Dubai. PSFT’s portfolio of clients in the region includes oil and gas majors, refineries and petrochemical producers in Saudi Arabia, Iraq, Oman, Kuwait etc and water markets in Egypt and Iraq, says a spokesman.

This local team works with customers to assess the right technology for their application requirements and deliver the most accurate and reliable flow metering and fire suppression solutions, he says. PFST’s operations comprise three business areas:

• Primary Flow Signal – leading designer and manufacturer of innovative, durable, and accurate differential pressure based flow-metering solutions;

• Turbines – rugged, stainless steel, precision machined turbine meters, monitors, and related instrumentation for a wide range of service requirements; and

• ACAF Systems-PFS Fire Suppression Group – the leading manufacturer of FM-approved compressed air foam-based fire suppression systems.

PFST’s flow meters and fire suppression products are designed to meet strict international standards and ISO 9001 compliance requirements for design, production and service, he says.

The company maintains a global presence with offices located in Rhode Island (headquarters), Houston and Odessa-Midland, Texas; Tulsa and Altus, Oklahoma; Seneca, South Carolina.

“We also have sales offices in Edmonton, Alberta, Canada; Beijing, China; and Dubai, UAE,” he says.

Referring to the importance of introducing efficient production technologies in the oil and gas sector, the spokesman says that according to the International Energy Agency (IEA) the cost of production of a barrel of oil including capital expenditures in Saudi Arabia and Iraq is very low compared to other countries.

In countries such as Algeria, Iran, Libya, and Qatar, field costs are higher, bringing barrel costs up to approximately $10 to $15. With oil prices hovering around $100, producers in Middle East and North Africa (Mena) region are investing in proven measurement technologies that provide longer life, better stability, and high accuracy.

For example a typical high performance venturi like HVT has standard warranty of 25 years which means operators can hedge against lower oil prices and higher cost of production in the future, with added benefit of no downtime thanks to little or no maintenance required for these devices.

“Measurement’s vital role in optimising oil retrieval and production can only be achieved with the industry’s most verifiable and accurate technologies,” he says.

There is a greater potential for return on investment in the Middle East as opposed to other areas, and implementing effective and accurate measurement technology is of the utmost importance from both a business profitability perspective as well as an environmental one.

From start to finish, drilling fluids, ground water, lubricants, asphalt, and the resulting, extracted oil-gas/fluid mix or “slurry” must be monitored. This ensures that companies receive accurate documentation of the amount of gas/oil recovered and also notifies engineers of any problems, such as fluid leaks or fissure expansions.

EFFECTIVE MONITORING TOOLS

To alleviate these issues, engineers and programme managers must implement appropriate measurement devices. For industrial-scale oil and gas retrieval monitoring operations, two flow metering technologies are uniquely proven in terms of high-accuracy results: differential Venturi and wedge-type metering; and turbine metering. These established technologies provide accuracy, value, and reliability monitoring clean and/or vicious fluids where others fail, he says.

DIFFERENTIAL FLOW RATE METERS

Differential flow meters, including Venturi meters and wedge-type meters, unlike many metering technologies, have no moving parts, which means significant operational expenditure and lifecycle savings for operators.

Accuracy is derived from the flow of liquids through their special design, and can be as good as +/- 0.25 per cent of actual rate of flow for Venturi meters that are independently lab calibrated, and +/-0.5 per cent of actual rate of flow in the case of the wedge-type products. As such, they are uniquely suited to provide high accuracy readings and reliability for oil and gas producers.

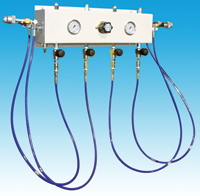

By incorporating sealed pressure sensors, highly accurate multi-variable differential pressure transmitters (including multiple transmitters for wide flow rate range applications) and in-place transmitter calibration options to either the Venturi or wedge-type meter installation; the user can enjoy significant cost savings, high accuracy, and long-term durability, he says.

The main elements for a successful metering system are:

• Modified short form Venturi: such as the PFS-HVT are more tolerant of upstream conditions. These meters have no downstream and shorter upstream straight pipe requirements for standard accuracy, have lower head-loss, and are less susceptible to blockages and plugging as the annular chamber was replaced with a single pressure tap. They are more accurate than most other meters as typical head-loss percentages for modified short form meters range from 3.0 to 10.0 per cent of differential depending on Beta ratio selected. In addition, the meter discharge coefficient is constant from 75,000 pipe Reynolds number and above;

• HBX meters: deliver metering accuracy, performance, and reliability over a wide flow range for a broad array of application requirements. With repeatable +/- 0.25 per cent laboratory calibrated accuracy and a stable linear coefficient, this design is ideal for full pipe flow of gas, liquid, and steam for applications, such as water, wastewater, oil and gas, industrial, commercial, and others. The meter discharge coefficient is constant from 6,600 pipe Reynolds number and beyond so this meter is ideally suited for low flows in an oversized line. In addition, the HBX does not need black box or signal conditioning due to linear coefficient of discharge;

• Wedge-type primary flow elements: differential metering for harsh service, highly viscous or contaminated line fluids, such as refinery fluids, raw sewage, sludge, tar sand, cement, or molten sulphur. In addition, the WedgeX design is derived from the standard wedge flow meter, but allows for a direct coupled differential pressure transmitter, which results in a compact and cost effective unit that virtually eliminates both gauge line induced and plugged tap related measurement errors. The unique advantage of the PFS WedgeX metering system is that it includes a direct mounted DP transmitter and instrument manifold;

• Differential pressure transmitters: provides accurate flow rate and totalisation readings for applications, including gas, water, cryogenic liquids, chemicals, and air as limited by materials; and

• Metering Scada system: shows real time values of pressure, flow rate, and totalised flow, and can display a real time trend for those parameters logging a trend history.

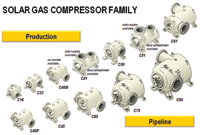

TURBINE METERS

Turbine meters are another technology with a successful reputation for delivering high accuracy for oil and gas applications. Industrial-strength turbine meters consist of a helical steel rotor, mounted on tungsten carbide bearings, that spins within a length of pipe, he explains.

Fluids flowing through it spin the rotor, with higher flows leading to higher speeds. As the rotor spins, a magnetic sensor in the housing picks up its speed by counting the rate at which rotor blades pass it and the output can be analog, serial, or pulse to suit control system needs.

As with differential meters, turbine meters can also be custom designed to fit their applications, and use a variety of materials depending upon the temperature, pressure, flow rate, and flow medium requirements, including level of viscosity. Materials are selected for durability, corrosion resistance, and value.

Turbines serve specific application requirements versus differential pressure devices, and, by nature, have a shorter service life.

By design, turbine meters and their internals are easy to replace. Turbines are meant to provide measurement for applications of a smaller scale than those typically seen in Venturi or wedge-type meters.

SELECTING THE RIGHT FLOW METER

Partnering with a trusted meter supplier is of paramount importance because the quality, reliability, accuracy, and longevity of a metering solution require a commitment to full-service design, manufacture, calibration, and ongoing service.

Faulty or inaccurate measurement can have enormous financial implications and directly correlate to revenue and profit. It’s therefore of the upmost importance that a company focuses on four key areas to ensure cost-effective and accurate flow meters for every element of the oil retrieval process:

• Quality: it’s important that a company designs and calibrates its meters, monitors, and flow controllers to the highest standards using independent verification and meeting all prerequisite certifications;

• Verifiability: independent calibration provides a greater level of insurance against low performance; suppliers who both in-house and independently calibrate offer a more conservative, and reliable option;

• Availability: fast-paced operations and demanding deadlines mean that accessibility to the right parts is imperative. Meter suppliers that can achieve quick delivery are critical to maintain peak production efficiency in the field; and

• Local Support: oil and gas producers have unique requirements and demand application expertise to recommend the right metering solution, and provide timely customer service when needed in the region where they operate.

CONCLUSION

The varying costs of oil production require an intelligent investment in superior technologies to enhance accuracy and reliability.

For the oil and gas retrieval process to remain a viable option for energy harvesting, responsible management and technology that includes proven measurement and monitoring solutions must help producers maximise the efficiency of their processes.

Therefore as measurement plays a vital role in optimising the oil retrieval process, only the most verifiable and accurate measurement technologies should be considered.

.jpg)