The Ras Tanura refinery ... a great success story

The Ras Tanura refinery ... a great success story

AS THE kingdom’s economy continues to power forward, it looks to Saudi Aramco to fuel that growth, and the company is proud to play that role. For almost 80 years, it has served as a catalyst for the kingdom’s prosperity and nothing better demonstrates this than the Ras Tanura Refinery (RTR).

It was back in 1941 that the refinery came online as a topping refinery with the purpose of fractionating crude oil at a rate of 3,000 barrels per day (bpd).

It was a historic year for the company; RTR was the kingdom’s first oil refinery. By 1945, its crude unit capacity had increased more than 15 times to 50,000 bpd, making the refinery a shining example of Saudi Aramco’s ability to grow.

Fast forward to 1986, and a new distillation unit had been added, which increased the refinery’s capacity to 250,000 (bpd) – a fivefold increase. And if that wasn’t impressive enough, after further expansion, the plant’s current processing capacity stands at 550,000 bpd – more than 183 times its initial capacity back in 1941.

“Ras Tanura Refinery is the largest complex of its type in the Middle East and one of the largest in the world,” says Omar Bazuhair, executive director of Refining and NGL Fractionation.

“Its growth, in many ways, has mirrored that of the company; it was one of the first installations built by the company, and it is not only going strong, but expanding. It provides the kingdom with a high percentage of its local demand. Based on benchmarking, it is considered to be one of the best refineries in the world. It plays a major role in supplying hydrocarbons that fuel the kingdom’s economy.”

In fact, the refinery meets 31 per cent of domestic demand for refined and natural gas liquid (NGL) products, making it an integral component in the kingdom’s economy.

“The kingdom’s domestic energy needs are growing by the day,” says refinery operations manager Uthman Al Ghamdi. “The refinery is pivotal in keeping local users and businesses supplied with the products that they require. Part of our mission statement is also ‘to pursue the most safe and efficient methods and to economically meet our share of the kingdom’s demand for refined and NGL products’ – so you can see how important we are for the future prosperity of the kingdom.”

In addition, as much as 1.2 mbpd of crude oil can be stabilised at the refinery for shipping to international customers. The refinery complex covers an area of 5.5 million square metres and serves three major operations: Refining, NGL and Oil Processing, and Utilities.

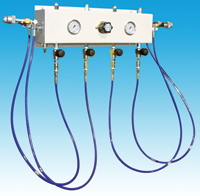

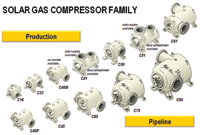

The mega-plant is self-sufficient in utilities, steam, power, compressed air and water requirements. The refinery generates 178 megawatts of power using four steam turbines and two, third-party cogeneration units.

To ensure greater reliability, the refinery electrical power system is tied to the Saudi Electrical Co. Eastern Region power grid. In the northern and southern refining facilities at the refinery, various crude oils are fractionated in distillation units.

These products are then further processed in downstream facilities to produce LPG, naphtha, gasoline, kerosene, jet fuel, diesel, fuel oil and asphalt. Most of the products that are refined in Ras Tanura are for domestic markets; however, naphtha is exported to international customers.

The refinery, like all company refineries, guarantees to supply its customers with the highest quality of products. But actions speak louder than words, and to ensure it lives up to its promise, the refinery relies on the analysis work carried out by the RT Laboratory, Saudi Aramco’s largest refinery laboratory.

Each day, about 90 highly skilled lab scientists, using almost 500 different pieces of equipment, analyse all processed stream fluids and finished products to produce close to 1,000 test results. These tests ensure that all products produced at the plant comply with strict specifications.

The lab received its ISO 9002 certification from the American Petroleum Institute, adding another level of quality assurance to customers. “We go that extra mile to achieve excellence,” says Yaser Sonbul, superintendent at the refinery. “By making sure our products are checked on a daily basis by an internationally certified laboratory, we show how much we care about those products and our customers. We don’t compromise on quality and safety.”

Emerging technologies and the company’s expanding portfolio means engineers and technicians always need to stay ahead of the game. Training and development, therefore, is of the utmost importance at the refinery. “We take the training of our staff very seriously, particularly our younger and new employees,” notes Al Ghamdi.

“Our Professional Development Programme (PDP) employees go through rigorous training. They are assigned a CMAP profile and given an individual development plan (IDP). During the three years of the programme, they are given critical tasks to complete related to their disciplines.

On the basis of their IDPs, young engineers will take short technical courses and assignments to develop them as competent engineers in their areas. “We also ensure that experienced employees have access to all the required training to keep them up-to-date with emerging technologies,” Al Ghamdi says.

For Sonbul, what makes the refinery so successful is its people – a net result of high quality training. “The three operational areas (refining, NGL and oil processing and utilities) are complex, but we have the staff and technology to ensure that operations run smoothly, and there is no disruption to supply.

“There are many key elements that work together to make the refinery what it is, but most importantly, the refinery’s great success is due to the hard work and dedication of its people,” he says.

.jpg)