Gould ... a sustainable strategy combines the best of software and hardware

Gould ... a sustainable strategy combines the best of software and hardware

The key to creating a truly sustainable digital oilfield strategy is combining the best available software and hardware. After all, hardware and software go hand in glove, says Howard Gould, Chief Executive of HMi Elements

State-of-the-art, bespoke hardware is playing a more important role than ever in helping companies deliver digital oilfield solutions and extract more oil and gas.

Multinationals including BP, Shell, Chevron, Schlumberger, Halliburton and Baker Hughes have harnessed digital oilfield technologies for some time and are now increasing these significantly.

While the adoption of digital oilfields has gained impetus in the past 15 years due to technological software advancements, hardware is equally vital.

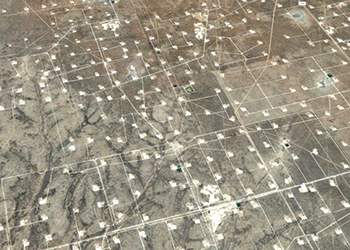

In essence, a digital oilfield aims to create a ‘digital twin’ – a replica based on data from sensors in the oilfield.

Yet hardware is central to the use of robotics, automation, sensors, AI, connectivity, control systems and the Internet of Things (IoT).

Hardware and software go hand in glove with wider benefits resulting in significant improvements to processes, workflow and productivity. Reliability is an essential part of digital oilfield technology.

At HMi Elements, we spent five years carrying out extensive research, development and testing for our new ground-breaking computer, the 1301-Z1.

Some may query the length of time taken but we were aiming to achieve a number of global firsts including glass edge-to-edge touchscreen and in-built firmware to monitor the health of the asset.

Relatively lightweight compared to all Zone 1 products that came before, easy access to the inside for easy maintenance, a futuristic appearance and multiple certification to Class 1, Zone 1.

You simply do not make IT hardware with ATEX, IECEx and AEx certification quickly.

From our experience – over 30 years as a specialist in the oil and gas sector – we know the amount of money and time we have dedicated to the 1301-Z1 is a wise investment and will pay dividends for customers because from this comes superior performance, quicker speeds, greater liability and product longevity.

For example, HMi computers have been used for 15 years in some of the harshest and most hazardous environments in the world.

They keep going and are incredibly reliable while at the same time easy to use and intuitive.

A key consideration relating to digital oilfield solutions is reducing costs and improving efficiencies so we have also taken measures to safeguard against any downtime by improving equipment diagnostics.

The unique hinged-front enclosure of the 1301-Z1 means for the first time computer hardware can be maintained in Zone 1 (a potential explosive gas atmosphere).

Another key consideration in developing a digital oilfield environment is health and safety, something that is quite rightly always a primary concern and likely to see a more powerful spotlight shone on it as we emerge from the COVID-19 pandemic.

Hardware is a prime consideration because of the very nature of where computers are used.

These are mission critical products being used by humans so must be capable of operating in temperatures ranging from -40°C to +60°C (-40°F to +140°F) and in conditions that see severe vibration and dirty power supplies.

Furthermore, all six sides must be waterproof and ingress protected to IP66/NEMA 4X standard given the presence of gas.

These are purely safety imperatives but the computer must be usable and serviceable with longevity providing spectacular return on investment.

In the 1301-Z1 this means glove-friendly touchscreen controls, edge-to-edge glass, a high resolution 1,000 nit display so it can be used in the brightest of environments, a choice of operating voltages, have tailored input connections and portability.

When all these factors are considered, the key to creating a truly sustainable digital oilfield strategy is combining the best available software and hardware.

Those who have adopted this approach are already seeing a significant boost in production and financial performance, improved efficiency and enhanced health and safety.

HMi Elements has over 30 years’ experience designing and manufacturing hazardous area-approved computers. It supplies the world’s leading oil services companies with its products and has a strong reputation for innovation, reliability and excellence. The company offers a range of Zone 1 and Zone 2 products suitable to help the sourcing and extraction of oil and gas. All HMi Elements products undergo the most rigorous of testing complying with ATEX, IECEx, AEx and CSA.

-is-one-of-the-world.jpg)

-(4)-caption-in-text.jpg)