Solving sample challenges with probes

Solving sample challenges with probes

Innovative HAG and ASR probes ensure safe, efficient sampling of toxic gases like H2S and SO2, with single-connection design, integrated safety features, and tailored sulphur management for reliable analysis, writes Niravkumar Patel, Technical Sales Support Specialist, AMETEK Process Instruments

Sampling toxic gases like hydrogen sulfide (H2S) or sulphur dioxide (SO2) for analysis poses significant challenges, primarily due to the high toxicity of these gases, the presence of high water or sulphur dew points, and the disposal of the hazardous analysed sample.

These challenges often lead to the abandonment of analysers due to safety concerns rather than mechanical failures.

An ideal solution to address these issues is a probe designed to require only a single process connection for both sample extraction and safe return.

Integrated with a built-in aspirator, AMETEK Process Instruments’ heated acid gas (HAG) and advance sulphur reduction (ASR) probes use instrument air, nitrogen, or steam as the driving force, managed by the analyser.

|

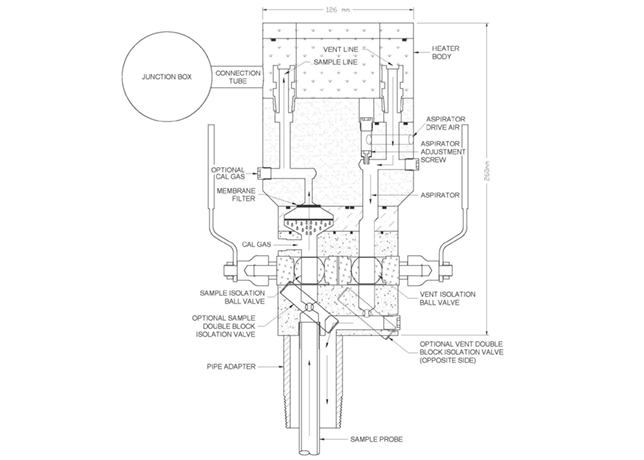

Figure 1 … heated acid gas sample probe |

When the analyser operates in the measuring/sampling mode, without faults or alarms, it draws the sample through heated lines from the process pipe to the analyser.

After analysis in the sample cell, the sample is returned safely back through the same connection.

This streamlined process ensures both efficient sampling and safety, making the system a comprehensive safety solution.

The probes are designed to effectively isolate and purge the entire analyser system before maintenance, eliminating the risk of H2S exposure.

HEATED ACID GAS (HAG) PROBE

The HAG sampling probe (Figure 1) is an advanced, electrically heated probe designed for seamless integration with AMETEK’s hydrogen sulfide analysers, such as the IPS-4 feed gas analyser.

It features integrated shut-off valves and a serviceable membrane filter to protect downstream analysers from liquids and ensures sample integrity with temperature control to prevent condensation.

|

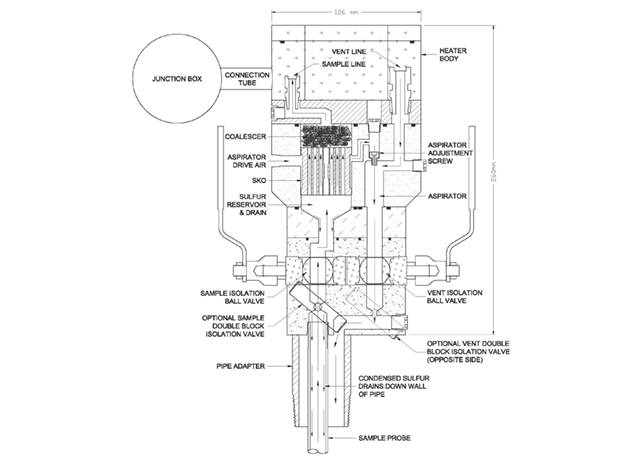

Figure 2 … basic ASR9000 |

With a single process connection for sample extraction and return, the HAG probe simplifies installation and maintenance, providing reliable sample circulation through its heated aspirator.

Compliant with NACE MR0175-2002, it is ideal for sour gas and sulphur recovery unit (SRU) tail gas treatment unit applications, combining efficiency and safety in a compact design.

ADVANCE SULPHUR REDUCTION (ASR) PROBE

The ASR probe (Figure 2) is a pivotal component for sulphur gas analysis, providing primary sample conditioning directly at the tail gas pipe.

It effectively removes sulphur vapour, fog, and mist using a centrifugal chamber and demisting mesh pad.

The probe features a temperature-controlled body with integrated components for sulphur reduction, including a condenser, coalescer, and aspirator.

|

Its unique design ensures safe and easy maintenance, with reduced installation costs and flexibility in analyser placement.

The ASR900 is essential for accurate sulphur recovery unit analysis and air demand monitoring, maintaining efficiency and safety in sulphur handling processes.

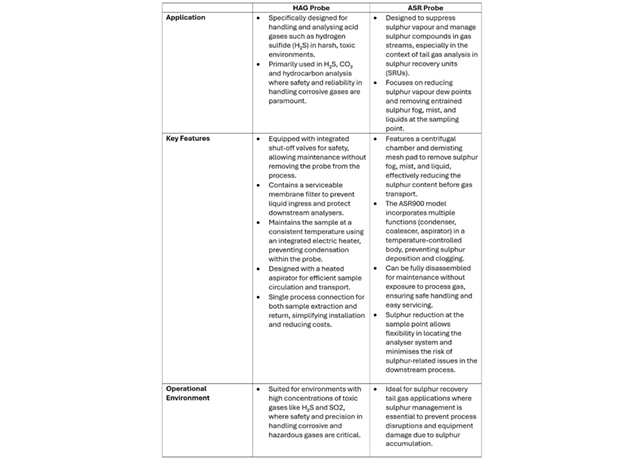

COMPARISON

The probes are designed to handle challenging gas sampling scenarios, but they cater to different applications and have distinct features (Table 1).

SUMMARY

The HAG Probe is optimised for safely handling and analysing corrosive acid gases, focusing on ease of maintenance and preventing sample condensation.

Meanwhile, the ASR Probe excels in managing sulphur in gas streams, specifically designed to reduce sulphur vapour and handle liquid sulphur, making it essential for sulphur recovery processes.

-is-one-of-the-world.jpg)

-(4)-caption-in-text.jpg)