The Abqaiq Plants is at the forefront of adopting 4IR technologies

The Abqaiq Plants is at the forefront of adopting 4IR technologies

The company is deploying a proprietary generative AI models and new supercomputing infrastructure to drastically boost efficiency, cut emissions, and lead the sector’s digital transformation

The energy sector is undergoing a profound transformation, and at its heart lies the synergistic power of artificial intelligence (AI) and big data.

This partnership, driven by the unprecedented creation and capture of massive, varied datasets at high speed, with Aramco alone collecting around ten billion data points daily, is enabling AI algorithms to solve highly complex industrial challenges, ushering in an era of unparalleled operational efficiency.

For Aramco, harnessing the combined might of AI, big data, and the Industrial Internet of Things (IIoT) is not merely an upgrade but a central pillar of its ambitious digital transformation programme.

By designing, developing, and deploying innovative smart tools, the company is fundamentally enhancing everything from workers’ safety and decision-making processes to reservoir management and power consumption, all with the strategic aim of remaining the most reliable and affordable energy supplier to meet the world’s growing demand.

Aramco is not simply adopting off-the-shelf AI; it is pioneering the field with bespoke industrial solutions, most notably with the launch of AramcoMetaBrain in early 2025.

This proprietary generative AI model, and the world’s first industrial large language model (LLM), is trained on Aramco’s vast operational data spanning over 90 years.

It is designed to provide actionable, real-time insights, optimise complex operations, and predict product quality.

This level of industry-specific cognitive power is a game-changer for the energy sector, offering transformative applications like SARA, an industrial Gen-AI tabletop voice assistant that provides highly contextualised, on-premise operational guidance.

The company’s drive for technological sovereignty is further evidenced by strategic collaborations with technology giants like Cerebras Systems and Qualcomm Technologies, alongside the deployment of a new AI supercomputer powered by NVIDIA GPUs, which is designed to accelerate complex computing tasks like analysing drilling plans and geological data to recommend low carbon intensity well placement.

FROM GIGABYTES TO GROUNDBREAKING GAINS

The strategic application of AI and big data is delivering tangible, quantifiable improvements across Aramco’s vast operational landscape, setting a new benchmark for digitalisation in the energy industry.

A significant area of impact remains flare monitoring, a critical environmental and efficiency concern.

Flaring, the combustion of excess hydrocarbon gases from pressure build-up, is being proactively managed by Aramco’s in-house-developed AI systems.

Engineers utilise big data from over 18,000 sources to visualise the entire gas processing system in real-time, allowing them to quickly identify flaring sources.

Sophisticated AI algorithms compare this live data to big data-modelled forecasts, predicting when a facility is likely to exceed its flaring targets.

This predictive capability allows for timely remedial action, helping Aramco to maintain an industry-leading flare volume of below one per cent of total raw gas production.

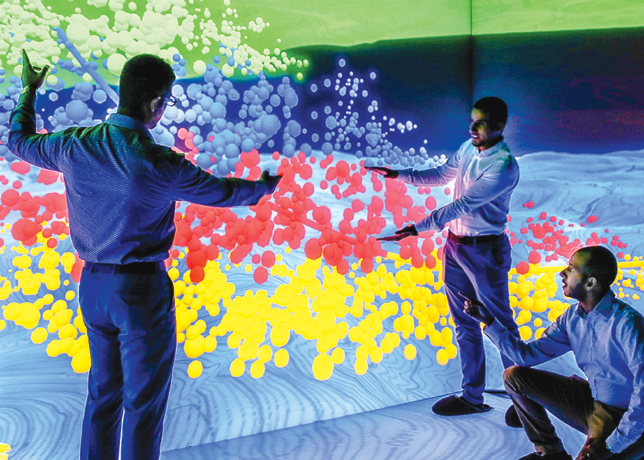

|

Harnessing technology is a central pillar of Aramco’s digital transformation programme |

The same technological prowess is revolutionising how Aramco manages its subsurface assets.

Reservoir modelling employs state-of-the-art digital visualisation and big data to simulate complex reservoir and basin challenges, guiding optimal development plans.

For instance, TeraPOWERS, the company’s reservoir and basin simulator, leverages big data to model the entire hydrocarbon system of the Arabian Peninsula.

These models are constantly refreshed with new drilling and production data, which sophisticated algorithms then analyse to improve access to hydrocarbon resources.

This marriage of massive computational power and real-world data is further enhanced by Dammam-7, one of the world’s most powerful supercomputers, which provides the necessary computational muscle to run detailed 3D seismic models, boosting engineers’ ability to discover and recover oil and gas with greater precision.

The benefits extend far beyond the underground and processing facilities, reaching the very process of drilling.

The Camera-Based Well Space Out system is an innovative IIoT-connected platform utilising smart, high-resolution cameras and sensors.

This system employs AI and machine learning to process imagery and video, automating and optimising the critical placement of the drillstring assembly.

Correct spacing is vital for the quick and easy shutdown of the well in the event of unexpected pressure changes, thus enhancing safety and efficiency during the drilling of new wells.

Furthermore, the company is actively integrating AI on the Edge solutions, working with partners like Qualcomm to deploy industrial generative AI directly onto IIoT devices for enhanced facility monitoring and predictive maintenance using autonomous drones.

This approach improves system security and drastically reduces latency in critical, real-time operations.

DIGITAL TRANSFORMATION IN ACTION

The scale of Aramco’s digital transformation is perhaps best illustrated by the operational improvements at its major facilities, a success story that gained further global recognition in early 2025.

In January, the North Ghawar Oil Producing Complex became Aramco’s fifth facility to be admitted to the prestigious World Economic Forum’s Global Lighthouse Network, making Aramco the only international energy company to be represented by more than three facilities.

This recognition, which follows the inclusion of Khurais and Abqaiq Plants, validates the comprehensive, at-scale adoption of Fourth Industrial Revolution (4IR) technologies.

At North Ghawar, the use of advanced analytics, AI-powered digital twins, and the Aramco LLM led to an 8.44 per cent increase in oil production alongside an 8.21 per cent reduction in Scope 1 and 2 emissions per barrel of oil equivalent.

At the Khurais oil field, one of the largest, more than 40,000 sensors have been deployed to monitor over 500 oil wells, creating the first advanced process control (APC) for a conventional Aramco oil field.

Harnessing big data analytics, machine learning, smart sensors, and robotics has delivered monumental gains, including a 15 per cent increase in oil production and a 100 per cent improvement in troubleshooting response times.

Similarly, the digital overhaul of the Abqaiq Plants has resulted in significant operational improvements.

Robots and smart drones now perform nearly a third of routine operations, reducing reliance on manual field checks.

Crucially, the introduction of machine learning and AI algorithms has enabled the automatic adjustment of the oil stabilisation process, leading to increased power generation performance and a reduction in CO2 emi1ssions at the facility.

Furthermore, a new partnership signed in July 2025 with Cloudera is focused on jointly developing and implementing data-driven solutions and upskilling local Saudi talent in data engineering and AI, cementing the commitment to both operational competitiveness and national technological leadership.

This systematic drive for digital excellence is supported by a robust network of digital development and innovation hubs, including the 4IR Centre, the Upstream Innovation Centre (UIC), and the Saudi Accelerated Innovation Lab (SAIL), which collectively collect billions of data points daily.

Through these strategic investments, partnerships, and proprietary AI developments like AramcoMetaBrain, Aramco is demonstrating how data intelligence is the ultimate catalyst for operational excellence, ensuring the company remains at the cutting edge of the global energy landscape.

-is-one-of-the-world.jpg)

-(4)-caption-in-text.jpg)