Interwell’s Medium Expansion Retrievable Bridge Plug

Interwell’s Medium Expansion Retrievable Bridge Plug

Advanced retrievable plugs and autonomous systems ensure safety, maximise uptime, and boost operational efficiency in complex, high-stakes well interventions

A cross diverse, high-pressure environments, Interwell utilised advanced retrievable bridge plugs and autonomous SAP management systems to ensure robust well integrity, minimising operational downtime, and optimising production efficiency under stringent time and safety constraints.

A client in the North Sea required temporary isolation of gas lift mandrels across nine wells to facilitate the safe replacement of gas lift valves.

The operation needed to be executed within a tight schedule and in a single mobilisation, with zero tolerance for tool failure, well integrity risk, or operational delays.

Maintaining efficiency while ensuring plug integrity, pressure validation, and a smooth retrieval process was critical to project success.

• Precision technology deployment: To meet the isolation requirements, Interwell utilised its Medium Expansion (ME) Retrievable Bridge Plug (RBP), selected for its proven field longevity and excellent operational track record across numerous deployments.

The system is known for its robust sealing performance and reliability in varying casing conditions.

The ME plug was deployed in each of the nine wells, providing secure and validated isolation across all targets.

Each ME RBP was pressure tested after setting to confirm wellbore isolation before valve changeout operations began.

The gas lift valves were then replaced safely and efficiently. Upon completion, all ME plugs were successfully retrieved without incident.

The ME plug’s simple and efficient design enabled fast deployment, effective sealing, and smooth retrieval; significantly reducing the risk of stuck tools or delays.

The operation was conducted within the planned timeframe, with zero mechanical failures or HSE incidents.

• Operational excellence achieved: This operation highlights Interwell’s ability to deliver high-efficiency Plug & Pull services under time constraints and without compromise to safety or performance.

By completing all nine wells in one go, the client minimised rig time, reduced logistics costs, and avoided multiple mobilisations.

Furthermore, the flawless retrieval of all plugs with zero NPT eliminated the risk of fishing or remedial operations; significantly enhancing operational uptime.

The success of this campaign clearly demonstrated the Interwell team’s capability to execute complex, multi-well gas lift interventions with consistent and repeatable results.

A-PRO MAXIMISING PRODUCTION ON SAP WELL

|

A-PRO is highly customisable can be integrated into an existing SCADA system or |

In a scenario, in the Middle East, wells with sustained annulus pressure (SAP) were in breach of OPCO well integrity policies.

Some SAP wells could be flowed under dispensation, and others, depending on their location, and the nature of the SAP, had to be closed in awaiting workover, resulting in significant production losses.

The case study describes the use of the PTC A-PRO™ system to address the well integrity challenges and autonomously manage SAP.

It led to eliminating the need to close the well in. The system also provided data to better understand the nature of the SAP.

Numerous alerts were also provided, at times when the well was no longer producing (due to external factors). Thus, further maximising production uptime.

• Well Integrity Issues: A remote location well, capable of producing approximately 1,500 stock tank barrels per day (stbpd), was suffering unplanned SAP.

Consequently, there were a number of locations on the wellhead annulus side outlets (and their associated gate valves/pressure gauges) where only a single barrier existed, to the escape of the pressurised annulus fluid. This breached the OPCO’s well integrity policy.

Concerns also existed that the SAP could, in time, approach the maximum allowable annulus surface pressure (MAASP).

The well was not connected to SCADA and regular OPCO staff visits were impractical. So, the well was to be shut in awaiting workover at a significant production deficit.

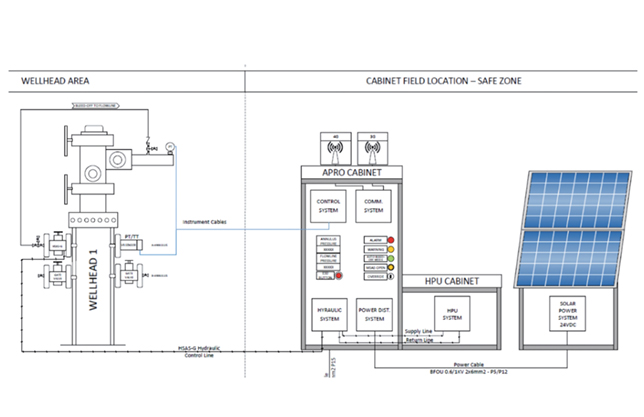

• Autonomous SAP management: PTC’s A-PRO™, the Middle East’s first fully autonomous SAP management system was installed on the well.

The highly customisable A-PRO™ utilises PTC’s VR Sense™ annulus pressure and temperature (P&T) sensor and HSAS™ Annulus Safety Valve, to restore double barrier integrity in the well.

|

A-PRO is Middle East’s first fully autonomous SAP management system |

In cases where SCADA and power is available at the wellsite, the VR Sense™ and HSAS™ can be integrated with existing facilities.

However, in this case, the A-PRO™ system, with solar power, HPU system and GSM communication was required.

The A-PRO™ data logger and control system continuously monitors the P&T data measured by the VR Sense™.

It also automatically manages the SAP between pre-set limits by opening/closing the HSAS™ Annulus Safety Valve, to facilitate annulus pressure blow down to the production flowline.

The system also sends reports, warnings and alerts, via SMS and e mail to the control room and selected operations staff.

• Sustained production benefits: When the A-PRO™ System was commissioned, the VR Sense™ and HSAS™ created the double barrier to prevent the escape of pressurised fluid from the annulus.

As a result, the well has continued to be produced at 1,500 stbpd, instead of being closed in awaiting workover.

Consequently, the system continues to operate reliably, logging data locally every 5 minutes (and at blow down events), then sending compiled data in report format every 12 hours to the field central control room and to selected operations staff, by email and SMS.

Moreover, the system has provided real time, annulus pressure and temperature data along with system status data ‘on demand’ via SMS, when prompted to do so by SMS message.

After 15 months in operation, the SAP reached the blow down trigger pressure (700 psi) and the A-PRO™ system performed as per its design.

Subsequently, the system opened the HSAS™, allowing the annulus pressure to be automatically blow down to 100 psi above the flowline pressure, before re-closing the HSAS™.

Additionally, having coincident annulus temperature data, along with the annulus pressure data, has proved to be very useful.

Through this data, an annulus pressure/temperature relationship ‘signature’ has been established.

In this case: Specifically, there is a consistent shape to the pressure/temperature changes, every time the well starts flowing or is closed in. This indicates the communication causing the SAP to be stable.

Furthermore, the Annulus Pressure increase is primarily due to the average temperature increase in the well, when the well is flowing.

In contrast, the fluid driving the SAP, can only enter the annulus during periods when the well is closed in (when the average temperature in the annulus is lower and the SAP is relatively low).

During production, when the well is flowing, the annulus heats up and the annulus pressure increases to a level, then stabilises.

This suggests that a balance point is reached where the source of the SAP is no longer leaking into the annulus when the well is flowing.

Additionally, annulus Temperature data gives a very clear indication when the well has unexpectedly stopped flowing (usually due to an unrelated downstream issue).

As a result, this data has been used on 18 separate occasions in the first 15 months alone, to alert the operations staff that for some reason the well was no longer flowing. This also contributed to optimising the production uptime of the well.

-is-one-of-the-world.jpg)

-(4)-caption-in-text.jpg)