Qamar uz Zaman

Qamar uz Zaman

Addressing long-standing challenges in debris management across horizontal and vertical wells, laser-focused magnets are helping enhance oil production rates, Qamar uz Zaman tells OGN

In oil and gas drilling, debris retrieval remains a persistent operational challenge, especially in high-risk wells where perforation efficiency directly influences productivity.

Traditional cleanout methods, including the use of conventional magnets, often failed to provide reliable results, leading to productivity loss and costly intervention.

However, laser-focused magnets has begun to redefine the approach, offering operators a more effective tool for unholstering well potential using converging shockwaves, Qamar uz Zaman, Operation Manager, Innovar Solution Middle East, tells OGN energy magazine.

FROM CONVENTIONAL CLEANOUTS TO LASER PRECISION

.jpg) |

Figure 1 ... Perforation length versus debris retrieved (kg) |

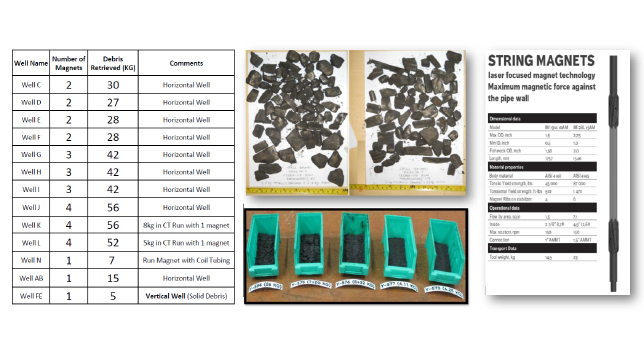

The limitations of conventional magnets became clear during Petroleum Development Oman’s (PDO) early trials in horizontal wells.

With gun assemblies exceeding 1,000 m and perforation intervals between 150 and 700 m, conventional debris recovery tools struggled to match the volume of debris with the actual gun length.

Initial attempts with two conventional magnets yielded inconsistent recovery, with debris weight failing to align with expected perforation lengths (Figure 1).

This inefficiency prompted PDO to collaborate with RAY International on an alternative solution.

Laser magnet technology was developed as a direct response. Unlike conventional tools, laser-focused magnets were designed to enhance retrieval precision and increase debris capture capacity.

Their deployment began with two magnets in trial wells, immediately demonstrating improved results.

In four wells, the technology achieved an average recovery of 28kg of debris per well, effectively doubling cleanout efficiency.

|

Figure 2 ... Debris collected using laser magnets |

Encouraged by this progress, engineers expanded the configuration to three laser magnets, retrieving 42 kg of debris per well, even when perforation lengths were shorter than in earlier jobs.

Eventually, a four-magnet setup achieved up to 56 kg in horizontal wells, with debris samples indicating not only material from perforation guns but also existing downhole debris (Figure 2).

These results marked a turning point: For the first time, operators had a scalable cleanout solution capable of adapting to varied well conditions, with each magnet offering a debris-handling capacity of around 14 kg.

CASE STUDIES HIGHLIGHT PRODUCTION GAINS

Beyond retrieval statistics, the deployment of laser magnets produced measurable improvements in productivity.

|

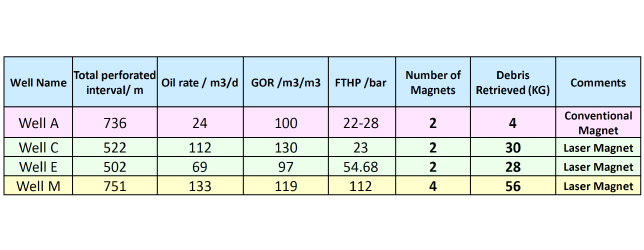

Table 1 ... Productivity data |

In Well C, with 522 m perforated using two laser magnets, the oil production rate reached 112 cu m per day, dramatically higher than Well A, which relied on conventional magnets and delivered only 24 cu m per d despite a longer perforation interval of 736 m (Table 1).

Similarly, Well M, which incorporated four magnets, produced 133 cu m per d, highlighting how improved debris removal directly influenced flow efficiency.

The benefits extended to vertical wells as well. Trials in Well FE demonstrated that even with shorter perforations, a single laser magnet retrieved 5 kg of debris.

Another vertical application confirmed 7 kg recovery, underscoring the technology’s adaptability across completion types.

In certain cases, magnets run prior to tubing-conveyed perforation (TCP) operations using coil tubing revealed pre-existing debris in the hole, further proving their diagnostic value.

PDO’s experience also revealed important operational adjustments. Acid stimulation runs, once considered essential to mitigate debris blockage in YK field wells, were eliminated after laser magnets ensured cleaner perforation tunnels.

This not only reduced intervention costs but also removed a step with potential environmental implications.

The detailed journey—from two magnets to four—illustrates a methodical process of technology validation and optimisation.

It also highlights the importance of examining debris characteristics, which informed decisions to run magnets ahead of perforation jobs, ultimately preventing tunnel plugging and production facility strain.

As case studies accumulated, the operational standard shifted. Engineers began correlating perforation gun strings with the required number of magnet joints, using case history to update standard operating procedures (SOPs).

The transition from experimental application to field-wide adoption demonstrated how rapidly the technology established itself as a new benchmark.

The future scope is also significant. With vertical wells showing promising early results, further studies are planned to refine magnet deployment strategies in these contexts.

The ability to scale across horizontal and vertical environments positions laser magnet technology as a versatile cleanout tool with lasting industry impact.

The success of laser-focused magnets reflects a broader theme in the energy sector: innovation rooted in practical field challenges.

By replacing underperforming conventional systems with precision-based alternatives, operators can unlock greater productivity, minimise operational risks, and reduce reliance on costly interventions.

For PDO and its partners, the technology not only improved performance in specific wells but also set a precedent for cleaner, more efficient well completions across diverse fields.

-is-one-of-the-world.jpg)

-(4)-caption-in-text.jpg)