Ras Tanura refinery's upgrade has enabled the Eastern Province plant to process higher value products and reduce the amount of lower value heavy fuel oil manufactured by the facility. The upgrade will also lead the way in the Kingdom's move towards unleaded gasoline.The completion of an upgrade programme at Ras Tanura refinery has been the highlight of Saudi Aramco's refining sector in the past year, according to the company.

The project, which came onstream last year, extends Saudi Aramco's drive to increase profit margins by configuring the plant to process higher value refined products from the crude stream and reduce the amount of lower-value heavy fuel oil products of earlier configurations.

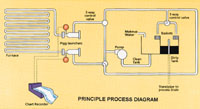

The upgrade included major new conversion facilities, including a 44,000 bpd hydrocracker, a 60,000 bpd visbreaker and a 40,000 bpd continuous catalytic reformer.

It will, according to president and CEO Abdullah Ju'mah, usher in higher capabilities for the Kingdom's refining operations and lead the way to lead-free gasoline.

Before the upgrade, the Kingdom had to import 20,000 bpd of gasoline, demand for which currently stands at around 200,000 bpd and is growing by almost 15 per cent per year.

The upgrade at Ras Tanura is the first of a series of enhancement projects at Saudi Aramco refineries, and the company says that Yanbu and Rabigh plants are scheduled for major development projects ''in the near future.''

But the project has not been completely without its difficulties, and a hydrocracker had to be shut down recently following several false starts.

The unit was originally due to come onstream in August 1998 but was postponed several times.

Traders have said that, as a result of the shutdown, Saudi Aramco had been prompted to use middle distillate supplies from its Rabigh and Jubail refineries to meet domestic demand.

Meanwhile, sources have said that a project for the production of mixed xylenes at Ras Tanura refinery has been cancelled as a result of unsatisfactory bids from potential customers.

The mixed xylenes capacity would have been 11,000 to 12,000 bpd, though some bidders were said to be seeking 16,000 bpd.

Saudi Chevron Petrochemical Company, a joint venture between Chevron Chemical and Saudi Industrial Venture Group, was said to be relying on the project to provide feedstock for a paraxylene facility in Jubail.

Ras Tanura is the oldest and biggest of Saudi Aramco's domestic refineries, coming onstream in 1945 with a capacity of 50,000 bpd.

Additional units were then added to the plant in following decades to raise capacity to 530,000 bpd. A decision was taken in 1983 to modernise the plant, with a new crude distillation unit (CDU) and vacuum unit installed to replace two ageing CDUs and two vacuum units. A sulphur plant was also built with the capacity to process 10.1 million cu ft per day of acid gas.

Sulphur recovery units came onstream in May 1986, followed by a new 265,000 bpd distillation unit in the October of that year. The second distillation unit's output included light and heavy diesel (30 per cent), fuel oil (30 per cent), naphtha (20 per cent) and kerosene (15 per cent).

In October-November 1990, Ras Tanura stepped up its crude throughput to 510,000 bpd, although in December 1990 a fire badly damaged one of the distillation units, cutting the plant's capacity to 265,000 bpd.

Saudi Aramco operates seven refineries in the Kingdom, two as joint ventures. The 190,000 barrels per day (bpd) Yanbu facility, the 140,000 bpd Riyadh facility and a 90,000 bpd Jeddah plant operate principally to meet domestic demand for gasoline, diesel fuel, kerosene and asphalt.

The 300,000 bpd Ras Tanura refinery also meets domestic needs while the 325,000 bpd Rabigh, 320,000 bpd Saudi Aramco Mobil Refinery Company (Samref) and Saudi Aramco Shell Refinery Company (Sasref) refineries are produce goods primarily for export.

Saudi Aramco supplies the refineries with every drop of their crude oil requirements.