Long recognised as Saudi Arabia's premier manufacturer of black and hot-dip galvanised welded steel pipe, Saudi Steel Pipe Company Ltd (SSP) is presently commissioning a new High Frequency Induction (HFI) welded steel pipe mill in Dammam, according to the company.

This new facility was designed and engineered by DMS-France with technical support from Shinho Steel Company of Seoul, South Korea.

At the heart of the factory is a solid-state HFI welding system (a technologically-advanced version of Electric Resistance Welding) provided by Elva Indukjson of Norway.

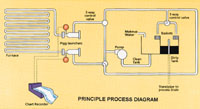

The welder control system has been customised to allow for a continuous monitoring of critical welding variables to ensure product integrity, the company says.

Beyond the welding system, the manufacturing process includes a 200 Mt strip accumulator to allow for steady state continuous feed of material to the forming and welding stations, edge milling of the strip to ensure the cleanest surface interface at joining, and computerised linear forming for precise shaping of strip prior to welding.

Then, too, the best online and offline Ultrasonic Testing equipment has been installed and will be supported by a state-of-the-art metallurgical laboratory.

The lab will be a focal point for collaboration on production matters, product development efforts, and Quality Assurance issues relating to customer and industry requirements, according to the company.

Product from the new mill will be targeted to the oil and gas industry in the Gulf.

In this capacity, the company will manufacture API 5L from GrB through to X70 in diameters ranging from 6" through to 16" in all standard wall thicknesses.

It is also intended that the mill will meet and/or exceed the region's commercial and industrial requirements for ASTM A53 and BS1387.

The plant has a rated capacity of 80,000 tonnes per year (tpy) on a one-shift basis.

This tonnage will complement the existing 80,000 tpy capacity at SSP's existing plant which is focused on black and galvanised welded pipe in the 1/2" to 4" size range, where SSP has served the commercial, agricultural, construction and industrial markets in Saudi Arabia and throughout the Gulf for 20 years.

In bringing this unique HFI mill onstream, SSP has recognised the need to educate the marketplace to the fact that not all welded steel pipe is the same.

There are many approaches to manufacturing the product and, consequently, each producing mill should be evaluated on its own merits.

To this end, the company has taken every opportunity to present a technical overview of the facility and its many unique features to various oil and gas industry events in the Gulf.

This presentation was developed for the explicit purpose of demonstrating that SSP's commitment to Continuous Electronic Process Control, when combined with the best available technologies in mill design, strip preparation and forming, and strong technical support will yield welded steel pipe of the highest integrity.

SSP is an industrial joint venture between Saudi entrepreneurs Rabiah & Nasser Co, Alkhorayef Sons Co and Fahad Mohd Al Saja, and Shinho Steel Company.

For further information, contact www.sspipe.com and/or John Breton, Product Development Manager at johnbreton@saudionline.com.sa