Latest technology keeps company one step ahead To boost productivity and keep its competitive edge in the national and world markets, Saudi Aramco makes use of the best technologies the world has to offer. It has also learned that technology works best when it is applied through team effort. In recent years, the company has overcome major roadblocks and resolved thorny problems by fostering cross-organisational teamwork and bringing a wide range of skills and expertise to bear on difficult challenges.

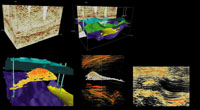

The company's ability to locate new oil and gas reserves and better manage existing ones has been strengthened with the opening of a Three-Dimensional (3D) Visualisation Centre in Dhahran.

The centre is a futuristic tool which allows petroleum engineers and geoscientists to interact with subsurface oil and gas field data in a ''virtual-reality'' 3D environment. The centre uses advanced computer graphics, wide-screen 3D capability and data integration to give teams of company experts an

''inside look'' at what happens in oil and gas reservoirs over time. The 3D Visualisation Centre - the first of its kind in the region and one of only a few in the world - encourages multidisciplinary teamwork and speeds up the decision-making process.

The POWERS reservoir simulator - developed in-house - has registered a quantum leap in its ability to provide detailed multimillion-cell reservoir description models, accurate reservoir characterisation and substantially shorter job execution times.

POWERS has been continually updated and enhanced with mathematical formulations and state-of-the-art visualisation technology. The simulator, which utilises parallel processing technology, is recognised in the industry as second to none.

Meanwhile, at Ras Tanura Terminal, one of the busiest petroleum tanker ports in the world, a new port control centre has been completed, enhancing safety and with it environmental protection.

As the centre of port piloting operations, the facility also acts as a focal point for the highly sophisticated vessel traffic management system (VTMS). This system allows for safer, more efficient tanker operations by preventing ship accidents and greatly reducing the risk of an environmental mishap.

Ju'aymah Gas Plant has also boosted its performance capabilities by commissioning a new power monitoring system (PMS) - the first of its kind in Saudi Aramco.

The system tracks power disturbances - both internal faults and those from the electric utility - and ranks them according to impact. Alarms are generated when necessary.

Elsewhere, Saudi Aramco's Oil Supply Planning and Scheduling Department (OSPAS) has completed an upgrade of its central dispatch system (CDS) which is managed totally in-house.

The CDS provides dynamic displays, diagrams and real-time data acquisition from both computers and remote field sensors. The system supports normal operations and planning, but it also alerts planners and dispatchers to any abnormal or dangerous field conditions.

The CDS has been expanded to include four additional company refineries and three bulk plants.

To improve operational safety and performance, a state-of-the-art Inspection Technology Centre has opened in Dhahran. Engineers can evaluate and develop new inspection technologies, train company employees and conduct nondestructive testing certification.

A separate building houses a specially shielded linear accelerator that generates industrial radiography energies of up to six million electron volts, allowing highly refined inspections of metal in pipelines and process equipment.