The Anabeeb Group of Companies provides a range of specialist contracting and industrial services to the oil, gas and petrochemical industries within the GCC and India.

The Group has evolved through 16 years of strategic growth and joint ventures into a market-leading, well respected business, having achieved ISO9002 accreditation since 1995.

Through this strategic expansion, Anabeeb is able to offer its services from facilities in Jubail and Yanbu in Saudi Arabia, Doha in Qatar, Abu Dhabi, Kuwait, Bahrain, Oman and India.

Anabeeb Services b.v was created in 1993 to assist the Middle East operations for overseas sourced quality procurement and other logistics and technological requirements.

To further strengthen the capabilities and technical expertise of the Group, Anabeeb has formed a series of partnerships with other world leading specialist companies, including Mourik International b.v in Holland; Teaminc, USA; Compagnie Technique des Petroles (CTP) of France; Kenny Manta, US; Contract Resource Services Ltd (CRSL) of Singapore; and DDT of Canada.

Anabeeb specialist services are provided through the industrial services division; chemical cleaning division; sludge treatment services; mechanical/maintenance division; leak repairs division; flare and chimney division; refractory engineering division; thrustboring services and pipeline services division.

Anabeeb is looking towards closer relations with its clients in the form of 'alliance partnership' agreements for maintenance which are linked to productivity incentives.

A vital model which Anabeeb is actively promoting is Total Productive Maintenance (TPM), which allows a plant to increase production without expanding production facilities by increasing service levels.

Thus, the optimum efficiency of plant equipment and availability is determined systematically with improvements and enhancements developed accordingly.

This optimum efficiency is linked to equipment maintenance procedures and procurement policies for new and to be replaced equipment. The established preventive maintenance procedures translate into production increases and lower plant costs.

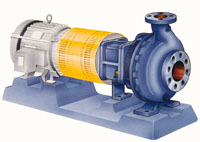

Anabeeb has available an extensive range of modern equipment for industrial cleaning work. High pressure cleaning and water hand-operated equipment (spraying guns and lances and crawling hoses) as well as mechanical equipment (rotating washers, drilling and lance equipment and sewerage cleaning equipment) are used.

Anabeeb cleans heat exchangers, condensers, reactors, storage tanks, furnaces, transport pipelines, sewerage systems, towers, vessels etc. in an efficient way. Specialised operations, such as water grit blasting, pressure testing of piping and vessels, high pressure ejection and catalyst removal, can also be carried out with the aid of different types of high pressure installations.

For bundle pulling, the Hydraulic Tube-Bundle Extractor is a self contained unit, which is lifted into position by just one crane. Using the extractor, it is possible to free most bundles in as little as 30 minutes. Once a bundle is resting completely on the extractor, the load is trimmed using the special hydraulic balancing cylinders.

Anabeeb has successfully pulled, cleaned and replaced well over 1,000 bundles of all diameters using its highly specialised personnel and equipment.

Vacuum cleaning services include the extraction of sludge, the emptying of towers, storage tanks, vessels, septic tanks and sewage systems, the exhaustion of separators and the removal of spilled oil. Large watering vacuum pumps collect dust and very light particles. The outgoing gas flow is cleaned, so that the exhausted gas can be recirculated or guided to a discharge system.

To complete the maintenance service lines, Anabeeb provides services for leak sealing, hot/cold tapping, internal line cleaning (decoke descale pigging), external online cleaning in combination with chemical cleaning, bolt tensioning and torquing and fabricating and the installation of plant parts or plant components.

In this context, Anabeeb has technical cooperation agreements/partners for specialised maintenance such as catalyst loading licenses, waste handling and sludge treatment/oil recoveries.

The DDT Service

This safe, simple method works better than steam-air decoking and chemical cleaning.

The DDT Service is an extremely effective, proven process which removes even the hardest coke and scale from furnace tubes. Instead of trying to remove these deposits by burning or dissolving them, the DDT process scrapes build-up away in a series of highly controlled incremental cleaning runs.

Because the DDT process is much more effective than steam-air decoking and chemical cleaning, you gain the economic benefits of increased run lengths, longer tube life, lower fuel usage and improved furnace reliability.

CTP On-Line Cleaning

A proven maintenance investment with a pay back of less than 30 days.

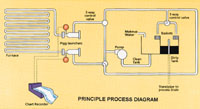

On-Line Anhydrol Process

Heaters are found in atmospheric distillation, vacuum distillation, visbreaking and hydrocracking units.

When they get fouled, the inlet flow to the reactor decreases, the tube metal temperature increases and the fuel oil consumption increases.

Anabeeb proposes the CTP On-Line Patented Anhydrol process. It consists of spraying with nozzles using a powerful air or steam jet as a support for a chemical product.

The Anhydrol process is double acting: a chemical action by oxidising the different deposits components and a mechanical action with compressed air which allows deposits to be carried away and eliminated.