Saudi Aramco Shell Refinery (Sasref) has started up its Thermal Gasoil Unit/Gas Turbine project (TGU project), the first major upgrade of the Jubail refinery since it was built in 1985.

Implemented by Foster Wheeler Italiana, the project was completed as per the planned schedule and within the approved budget, according to Sasref.

It took 26 months, from basic design and construction to start up, utilising three million man hours in the process.

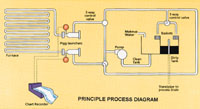

The TGU is operating with an intake of 5,650 tonnes per day (tpd) of atmospheric residue, and has the ability to process more than 300 tpd of hydrocracker bleedstream.

The cogeneration part of the project is a GT fuelled by natural gas driving a 33MW electricity generator, an equivalent of 60 per cent of current electricity consumption at the refinery.

The hot GT exhaust gas stream is used in a heat recovery unit to provide the process heat for the cracking furnace as well as to generate medium pressure steam.

The advanced Shell Thermal Gasoil Process technology used in the project is the first of its kind in the region. The unique design of the TGU/GT gives 60 to 70 per cent lower emissions and a 20 to 30 per cent overall efficiency improvement, according to Sasref.

The TGU operates on a mix of Long Residue from the crude distillers and surplus short residue from the high vacuum unit.

The TGU's run length is up to 18 months, while the GT cogeneration system will reduce the refinery's demand for electricity from external sources.

The TGU/GT unit will increase the conversion capacity of Sasref by converting long residue into valuable middle distillates, and is thus expected to improve Sasref's profitability and enhance the company's competitive marketing position internationally, according to the company.

The design of the Sasref TGU combines electricity generation with robust residue conversion technology. The TGU features a residue and distillate cracking stage, linked to each other via a so-called Combitower.

In order to obtain maximum distillate conversion, all internal plant cracked residues are vacuum flashed prior to routing to fuel blending.

Both cracking stages are combined in a waste heat recovery unit behind a Frame 6 General Electric Gas Turbine.

Sasref is a 50:50 joint venture between Saudi Aramco and the Royal Dutch/Shell Group.

An export refinery, the refinery processes Saudi Aramco's Arabian Light Crude to produce approximately 300,000 bpd of refined products, which include gasoil, chemical grade naphtha, dual-purpose kerosene and fuel oil. LPG, benzene, mogas, long residue and sulphur are also refined at the complex.

Aside from the TGU, the Jubail complex consists of two crude distillation units each of 150,000 bpd capacity; a 44,000 bpd hydrocracker and an aromatic section capable of producing 5,800 bpd of benzene with a 19,000 bpd continuous reformer at its heart.

Sasref's refined products are lifted by the marketing arms of both Shell and Saudi Aramco.

Excellent terminal facilities and Jubail's proximity to key export routes on the Arabian Gulf give the refinery a competitive edge in exports to the Middle East, Asia and the Pacific.