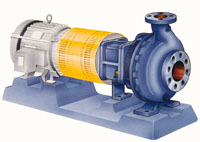

Riyadh-based Saudi Pump Factory (SPF) has taken another innovative step with the introduction of a new line of ANSI pumps for tough applications.

The ANSI B73.1 Process & Chemical pumps are the product of SPF's centrifugal process/chemical pumping plant, and are designed for the erosive and corrosive liquids found in the process and chemical industry.

The heavy duty pumps, known as the ANSIPlus Series, have been developed using SPF's unrivalled experience and design and application know-how and expertise, and are now being used with success in a range of industrial applications.

Featuring heavy duty power frames and casing designs, maximum wear life (giving minimum downtime), high shaft and bearing strength, maximum bearing protection, a semi-open impeller design with pressure relief holes, rotodynamic sealing and available in a variety of material, gland sealing and baseplate options, the ANSIPlus range can generate up to 200 HP on 60Hz or 50Hz power supplies, have NEMA or European Standard Motors and offer full safety guards around all rotating parts.

In the chemical and petrochemical sectors, applications include non-API610 process/chemical; process transfer and effluent and chemical transfer and effluent. The pumps are also being used in the industrial process, paper and pulp sectors.

The ANSIPlus range is the latest in a long line of high quality fire, API610 process and vertical turbine pumps designed and manufactured by SPF using state-of-the-art technology. The SPF manufacturing facility on Riyadh's Second Industrial City includes two- and four-axis CNC machining centres, as well as a computerised pump testing facility, including NPSH. End suction and split case pump casings of up to 1.3 tonnes can be made.

In addition to its in-house manufacturing capabilities, SPF has technical cooperation agreements with internationally-renowned companies including Aurora Pump of the US and David Brown Union Pumps of the UK. Such agreements enable SPF to widen the scope of its business opportunities, and, together with professional after sales support in Saudi Arabia and a stringent quality policy in force in the manufacturing process, SPF offers a complete service to its clients.

Through a policy of 'Providing Partnership' to its customers, the company says that it is now at the leading edge of valve and pump manufacturing technology for the oil, gas, petrochemical and industrial sectors. From Saudi Aramco to Sabic and a host of other satisfied clients throughout the Middle East, this ISO9002 certified manufacturer says that it can help reduce downtime thanks to the build quality and extensive range of products.

By forming strong, dependable relationships with highly respected contractors and consultants in Saudi Arabia, SPF is increasingly specified by name as the recommended supplier. And the company remains the only pump manufacturer in the Kingdom to be approved by Saudi Aramco.