Khurais ... a company showpiece

Khurais ... a company showpiece

ALL the people at Saudi Aramco are working toward the same goal — to remain the world’s most reliable supplier of energy while transforming into a world leading integrated energy and chemicals company. Roughly one in every eight barrels of oil produced around the world today comes from Saudi Aramco.

Saudi Aramco’s upstream operations continue to lead the industry in scale of production, operational reliability and technology development.

In the past years, the company has increased its crude oil production when needed to address market supply imbalances, providing crucial stability to the global market, and it continues to make massive investments to maintain the world’s largest spare oil production capacity.

Saudi Aramco continues to maximise the potential of its hydrocarbon resources by focusing on sustainability and using technology to maintain its positive trajectory of improvement in reservoir recovery, reliable operations and production.

The year 2013 also saw the company make significant progress on two offshore developments: Manifa, the world’s fifth largest oil field, and Karan, the kingdom’s first nonassociated offshore gas field. The company added new oil and gas reserves as it continued to implement the largest exploration programme in its history.

Saudi Aramco added three oil and two gas discoveries to its portfolio, bringing its total number of discovered fields to 121, Aramco says in its Annual Review 2013.

This included exploration and drilling operations in the deep waters of the Red Sea, where the company made a new oilfield discovery at Al Haryd, in addition to its previous gas find at Shaur within this frontier region.

In Saudi Aramco’s core operational areas, it found oil in Duhul and Salsal and discovered new conventional gas fields at Turayqa in the Rub’ Al Khali and at Mihwaz in central Saudi Arabia.

These discoveries are integral to supporting the company’s critical gas business, which is geared toward meeting the kingdom’s domestic energy needs and powering industrial development. Saudi Aramco’s unconventional gas programme also became fully operational in 2013, offering a promising new resource for the kingdom’s energy needs.

The company’s world-class research and development facilities have furthered its ability to explore for and maximise extraction of the kingdom’s resources, especially in challenging, complex environments. This work lays the foundation for exciting opportunities both in the present and the future.

In 2012, Saudi Aramco’s frontier exploration programme in the Red Sea resulted in a significant gas discovery at Shaur, which it viewed to be a potential game changer in the future of the kingdom’s energy mix.

In 2013, the company continued exploration and drilling operations in the Red Sea’s deep waters, where it made a new oilfield discovery at Al Haryd. Also in 2013, the first deep water Drill Stem Test operation for the company was successfully executed at Duba-1, located in the Northern Red Sea.

Tests conducted in sea water at a depth of 2,127 ft indicated tight reservoirs for potential future development.

MANIFA

The Manifa crude oil increment has been a monumental achievement in company history in terms of production, technology and manpower.

For the first time in the company’s history, a programme has combined onshore, offshore and a causeway in a single project.

In addition, the project has broken world records in reservoir engineering, drilling and well servicing.

Two world records were set in the Manifa field by drilling the deepest 61/8-inch hole section to over 37,000 feet and deploying the longest 7-inch liner with a length of over 18,000 feet to a depth of 26,000 feet.

The Manifa field was successfully put into production in April 2013, three months ahead of schedule, and achieved 500,000 bpd capacity by July 2013. By the time it reaches its full potential at the end of 2014, the Manifa field will have the capacity to produce 900,000 bpd of Arabian Heavy crude oil, 90 million scfd of gas and 65,000 bpd of condensate.

|

Shaybah ... key strategies in place |

It will also deliver feedstock to Jubail and Yanbu. The project consists of 41 kilometres of causeways, three kilometres of bridges, 27 drilling islands, 13 offshore platforms, 15 onshore drill sites, water supply wells, injection facilities, multiple pipelines and a 420 MW heat and electricity plant. Saudi Aramco hired 360 young Saudis to operate and maintain Manifa under the supervision of more experienced company employees.

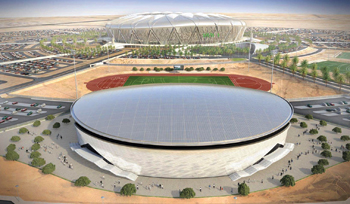

KHURAIS

The Khurais crude oil increment has become a company showpiece to visiting dignitaries and an example of the company’s ability to handle megaprojects with a keen eye on the values of safety and excellence. Commissioned in May 2009, Khurais currently has the capacity to produce 1.2 mbpd of Arabian Light crude oil, 70,000 bpd of condensate and 320 million scfd of gas.

In 2013, Saudi Aramco began a project to expand crude oil production capacity to reach 1.5 mbpd of Arabian Light by 2017.

The expansion project capitalises on the successful design of the Khurais Central Processing Facility to accommodate an additional 300,000 bpd of production and 500,000 bpd of water injection capacity. The facility’s design is engineered according to the highest industry standards and places specific emphasis on sound, environmentally friendly processes.

Khurais wells employ the latest Intelligent Field technologies, including real-time rate measurement and remote control and surveillance capabilities. Its best-in-class reservoir development plan was designed using GigaPowers, Saudi Aramco’s powerful proprietary reservoir modelling technology, to produce a high-resolution model to simulate optimal reservoir performance.

In addition, an accelerated evaluation programme was successfully completed to capture fluid and reservoir properties and performance, allowing Saudi Aramco to develop new reservoir targets.

SHAYBAH

Two major projects were in progress at the Shaybah field in 2013. First was a 250,000 bpd oil production expansion increment, which will be completed by the end of 2015.

The expansion will provide the Shaybah field with a capacity of 1 mbpd of Arabian Extra Light crude oil, double its initial capacity when it came online in 1998.

In 2013, the Shaybah drilling plan continued with two key strategies in place to maximise recovery: the first to place wells at deeper locations away from the gas cap to maximise oil recovery, and the second to increase the average reservoir contact from 6 to 10 km, enhancing production from the deep, tight faces of the reservoir.

Second was the construction of a new NGL recovery plant that will be completed by the end of 2014 with a production capacity of 275,000 bpd in line with the company’s corporate strategy to maximise revenues by significantly boosting the recovery of resources.

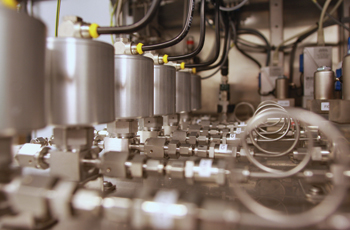

WASIT

Saudi Aramco made major progress on the Wasit Gas Plant in 2013, as site development, temporary facilities and communications were nearly complete by the end of the year. When it is completed in 2014, Wasit will be one of the largest nonassociated gas plants the company has ever built.

As a stand-alone gas plant, Wasit’s integrated facilities will process 2. 66 billion scfd of nonassociated offshore Khuff gas from Arabiyah and Hasbah. Along with Karan, it will raise the kingdom’s gas processing capacity by about 40 per cent.

Under normal conditions, Wasit is expected to supply 1.7 billion scfd of sales gas to the Master Gas System and have inlet facilities potential of up to 3.05 billion scfd of raw gas during emergencies or demand peaks. The plant also includes one fractionation module designed to produce ethane, propane, butane and natural gas.

The cogeneration facility at the plant will generate 750 MW of power and is expected to produce 4,200 metric tonnes per day of molten sulphur. As part of Saudi Aramco’s energy efficiency efforts, Wasit will also be the first in the kingdom to use Sulfinol-M gas treating technology to improve the efficiency of sulphur recovery units from 95 to 99.1 per cent.

MIDYAN

In 2013, Saudi Aramco launched its first project in the Tabuk region in the kingdom’s northwest, where procurement and construction work for a gas plant in the Midyan gas field is under way.

The Midyan field, discovered in the early 1990s during the Red Sea coastal plain exploration, was studied to identify ways to optimise economic production. The facility will be fully operational by 2016, at which time it will be capable of producing and processing 75 million scfd of nonassociated gas and 4,500 bpd of condensate.

The Midyan project will include the establishment of two pipelines stretching 98 kilometres to deliver sales gas and stabilised hydrocarbon liquids to a sophisticated power plant near Duba to generate electricity with high efficiency and to avoid burning high-value diesel. This is in line with Saudi Aramco’s strategic vision to respond more efficiently to the needs of its growing customer base.

FADHILI

One of Saudi Aramco’s goals throughout its strategic transformation is to improve capital efficiency by 20 per cent.

As part of that initiative, in 2013 the company held a workshop of the first Integrated Project Team (IPT), which was formed to plan and execute the Fadhili Gas Plant Programme.

The project team is planning the delivery of a mega-project that brings nonassociated gas from the onshore Khursaniyah field and the offshore Hasbah field.

The Fadhili IPT was joined by members of the newly established Capital Programme Efficiency and Value Assurance organisation in a workshop that focused on capital efficiency.

As Saudi Aramco’s capital expenditures increase to meet domestic and global demands, the 20 per cent efficiency potentially represents billions of dollars of cost avoidance that can be used for the benefit of the kingdom.

HARADH

Haradh Gas Plant successfully increased its capacity by 8 per cent to 1.95 billion scfd following the completion of the sales gas compression relief system, using in-house resources.

This enables the plant to process an additional 150 million scfd when the need arises.

-(3).jpg)