Unique diamond wire pipe cutting services

Unique diamond wire pipe cutting services

UNIQUE Wellube, a division of Unique Maritime Group (UMG), which is one of the world’s leading integrated turnkey subsea and offshore solutions provider, offers specialist engineering services and associated products to a diverse range of industries.

“The services are focused on ensuring plant and pipeline operability and avoiding costly unplanned shutdowns by allowing intervention and plant critical maintenance work to be carried out in a safe and cost effective manner,” says Sahil Gandhi, managing director, Unique Wellube.

Unique Wellube’s range of products and services includes: hot tapping and line stopping; on-site machining; under pressure leak sealing; Uni-Test online valve testing; uniseal pipeline repair clamps; on-line valve maintenance; composite wrapping; portable onsite machining sales and rentals; custom pipeline fittings; pipeline pressure testers; and wellhead and platform decommissioning services.

RECENT ACHIEVEMENTS

The company has received several high profile projects over the last year from some of the major companies in this area. A few of the projects are the following:

• Successfully completed four off 8-inch Class 600 subsea line plugging operations, Offshore Saudi Arabia at a depth of 50 meters;

• A 24-inch Class 900 double position line stop project has also been awarded for the repair of a high pressure natural gas pipe in Kurdistan;

• 500 UniSeal self sealing pipeline repair clamps of sizes ranging from 2-inch to 48-inch of pressure classes up to 1500 # were supplied to clients in Qatar, Oman, Kuwait and Iraq. Some of these were special builds with 2+ metre seal lengths;

• Leak sealing operations on 10,000 psi rated leaking wellheads in Iraq were successfully completed;

|

660 by 5t Unique Seaflex modules on swamp pull of 2,300 m of 3-pipe bundle |

• 18-inch class 900 subsea hydrocarbon leak sealing at a depth of 75 metres in Malaysia;

• Flange and tube sheet machining of 8 amine regeneration reboilers in Kazakhstan including planarity check and In–situ machining of heat exchanger gasket seating area of tubesheet (front and back side) channel flange and shell flange;

• Design, manufacture and successful testing of extended mechanical seal plugs to replace defective section of the 8-inch oil riser at OCCP platform. The plugs had to be installed 2 metres from the open end of the pipe to facilitate cutting and re-welding.

MAIN PRODUCTS

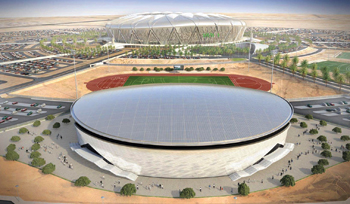

The company offers specialist hot tapping and line stopping equipment for numerous live interventions on pipeline systems. From the smallest bore emergency operation to large project planned interventions, Unique Wellube can successfully carry out live insertions into the plant without any need for production down time or interruptions in service.

These services come with the following features and benefits: services available with local expertise and equipment for hot taps up to 84-inch diameter; full size on size or reduced branch size on any pipeline materials and line mediums; topside and subsea; offshore and onshore; at any orientation – vertical/horizontal/offset/lateral; high pressure and high temperature capabilities; thermowell and probe installation online or tapping into storage tanks; extruded or fabricated fittings designed to client standards and requirements; and highly reliable and cost-efficient for all applications.

“All equipments are based within the region to meet emergency client requirements to cover all standard hot taps as well as single or double position line stops with/without bypass,” says Gandhi.

Unique Wellube has recently added the diamond wire saws to its existing range of products. These are typically used for subsea and topside multi-string casing and structure cutting. The wire saws have the following features: rigid frame makes repeatability and back-cutting easier and more accurate; operates in the most challenging environmental conditions; powerful dual drives cut through the toughest steel and aggregates, with less hang-up from pinching; compact and lightweight design takes less deck space and is easy to handle; continuous loop diamond wire resists breaking, makes multiple cuts with a single wire and small footprint saves deck space, reduces excavation for BML cuts.

It also maintains a stock of clamshell pipe cutting machines, flange weld testers and pipeline plugs. The clamshell pipe cutting machines find their usage in the oil and gas, power generation, shipbuilding and other industries that provide spark free, precision cuts and weld preps.

Some of its prominent features include: precision cutting and beveling of all pipe sizes, schedules and materials; highest industry standards for quality and cost; heavy duty, fully portable and can fit almost anywhere; sizes available locally from 2-inch up to 63-inch; pneumatic or hydraulic drive as required; and special options include: counter-bore attachment module, single point module and axial feed weld overlay removal module.

The flange weld tester (FWT) is used to test the integrity of a new weld joint by hydrostatic testing methods. It allows for a fast and efficient operation to be carried out using standard hand-tools for hydrostatic testing of a new weld.

|

Gandhi ... ‘our next stop will be at Adipec’ |

Pipeline plugs (PP) are widely used for hydrostatic test applications. This range includes low, medium and high pressure pipeline plugs. Apart from being used in a testing scenario, these pipeline plugs are also used for isolation and in some cases for very basic pig launching.

“The design of the FWT and PP has been created to make the tool efficient and simple to use as well as extremely cost effective to the operator in terms of time and money. There are easily installed and simple to use. They are also applicable in any pipeline material, reduce operational costs and minimise downtime,” Gandhi explains.

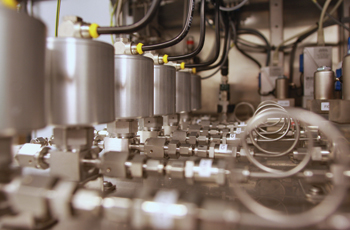

Unique Wellube also offers the Uni-Test on-line safety and relief valve testing system which is ideal for testing valves without the need of increasing the line pressure and removing the valve.

“The primary device used to prevent over-pressurisation in any onshore or offshore installation is the pressure safety valves (PSV). The primary function of a PSV is, therefore, to protect life and property and it is paramount to ensure that the PSV will operate as designed. The Uni-Test system is used to verify the set pressures of the PSV and also to ensure that it lifts when required, thus, eliminating the need to remove the valves from the system. Uni-Test can be used for testing when the plant is operational or even during shut down,” Gandhi says giving the details.

“The principle of the on-line valve testing is to apply a force to the valve spindle to overcome the spring tension of the valve. This is achieved using a hydraulic power pack in conjunction with an electronic force transducer linked to a digital recorder that controls and records the force applied. The recorder data together with knowledge of the valve seat area and the line pressure of the valve enables the set pressure to be calculated. Unique Wellube tests the valve with no interruption to plant production, thus, achieving considerable cost savings and operational advantages,” he adds.

“Additionally, the valve is also free to function normally throughout the testing operation. In addition to its ability to keep the process systems operational even during the testing, Uni-Test enables the recording and verification of the set pressure, reseat pressure, spring rate and valve displacement,” he says.

Some of the benefits of using Unique Wellube’s Uni-Test system include: TÜV and DNV approved; BV certified system; certificate issued for every valve tested; all spring operated and pilot operated valves can be tested; enables testing of response pressures without increasing the operational pressure; avoids down time and labour costs associated with valve removal/replacement; eliminates costs for transport of the valves and avoids possible damage to valves whilst in transit; efficient digital management of test data including settings and results; only valves that require overhauling can be removed from the line; and temperature compensation is not necessary for set pressure as the test is being executed at actual site operating conditions.

Unique Wellube is participating in the upcoming Adipec exhibition. “During the event, a host of products and services will be exhibited. These include the flange and pipe weld testers; Uni-Test online valve testing equipment; diamond wire equipment and the pipe spool which includes the hot tapping machine,” Gandhi adds.

-(3).jpg)