The HiP management team ... committed to continuous improvement

The HiP management team ... committed to continuous improvement

EVERYONE is a leader in the company. Everyone shows responsibility for their part of the team effort and tries to improve it. This is the philosophy at High Pressure Equipment Company (HiP).

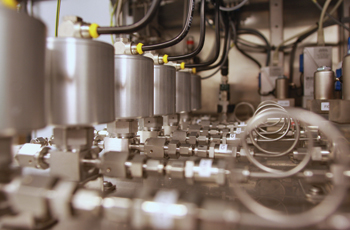

High Pressure Equipment Company (HiP), a manufacturer of specialty valves and fittings for elevated pressure applications, was located at a small manufacturing plant in west Millcreek, with just under 50 employees in 2012. That year Wasserstein & Co, an independent private equity and investment firm based in New York City, invested in a majority ownership of the company. The James family, long-time owners of the company, and the management team retained a minority share of the business as a commitment to the employees.

Under the new ownership, the company moved to a much larger facility during the spring of 2013 and expanded its organisational structure by almost doubling the workforce. Employees from within the company were promoted and professional positions were created to fill the new structure.

During the change, president, Larry Loper, and CFO, Larry Serafin, had a vision and goal of increasing their own leadership ability along with that of the entire plant. President Loper says: “My goal is to create a new climate in our company. I want everyone to take leadership responsibility for their job and treat it like it is their own company. I want them to think as if they owned the company, and try to improve it.”

Loper and Serafin’s vision led them to hire business consultant, Dr Bruce Swanson.Dr Swanson, worked as a human resource and training manager at Lord Corporation for over 20 years. He understood the manufacturing industry and its people, having worked as a machinist early in his career. Most importantly his passion for teaching leadership and emotional intelligence, along with his belief that Everyone is a Leader, made Swanson the best fit for HiP.

President Loper’s vision to create a new culture in the company and to create an entrepreneurial workforce that looked upon their individual jobs as if it was their own company, required a major investment in time, money, and limited resources for a small company that was growing and competing in a global marketplace. However, with the efforts of all, this investment in people is changing the culture at HiP.

How did HiP do it? The consulting team along with the management, decided to take a Top-Down approach. Top management, including both Loper and Serafin, were trained on the same basic principles as those on the production floor.

A unique customised leadership training programme was designed by the consulting team to accomplish HiP goals. The major goal of the programme is to create value for the customer and eliminate waste. Trainees are taught that the customer will only pay for “value”.

Seven HiP Leadership Principles were created to be a guide and a focus for the trainees. These principles are: Everyone is a leader; leadership begins with an awareness of one’s self; leaders should have an entrepreneurial outlook; leadership is situational and dynamic; leaders are trainers; leaders are change agents; and leaders have vision, both professional and personal.

|

Larry Loper, president (left), Donald Glover, machinist (centre), and Sarah |

Seven HiP continuous improvement principles were also created to focus employees on “Creating Customer Value.” These principles are: everyone works to create value for the customer; teamwork is essential. Everyone works together to help each other; everyone is a leader and follows the HiP seven “Leadership Principles”; everyone takes responsibility to eliminate waste in the process; improving processes and eliminating waste is the goal; the focus each day is on the customer/supplier relationship and each individual takes responsibility to improve his/her value and to become more effective and efficient.

The training is designed to be very interactive with case studies based on real situations and everyday issues in the plant. Every week participants engage in spirited questioning and discussions. Trainees are taught a variety of quality and management tools to solve issues and problems in their areas, while competing in a dynamic, global marketplace. Personal responsibility, continuous improvement, quality, and adding to customer value are expected. The focus on the fundamentals and improving the process are keys to success. The great basketball coach, John Wooden, said: “The secret to success is a lot of little things done well.” This is one of the philosophies at HiP.

The following is the basic typical training that everyone (managers and production employees) receives:

• HiP seven leadership principles;

• HiP seven continuous improvement (customer value) principles;

• Emotional intelligence: self-awareness, self-discipline, self-motivation, understanding/caring and interaction principles;

• Goal setting/planning;

• Basic business principles (value streams, profit margins, etc);

• Effective listening and communications;

• Leadership and life management programme;

• Avoiding conflict; and

• Teamwork.

The management team also received additional training in the following areas: performance review process/evaluations; coaching and mentoring; performance improvement; managing conflict; motivation; presentations to small groups; 360-deg evaluations; and team leadership.

Everyone has gone through, or is going through, a basic leadership training programme with the management team receiving more training as is appropriate for the position.

The basic programme is designed to be delivered during a sixteen-week timeframe with the trainees meeting approximately one hour per week, while the management team meets every week for continuous training and development.

One of the keys to success at HiP has been the fact that the entire management team has personally gone through the training programme. The management team has also conducted a 360-deg review process for each team member in the leadership area. The management team continues to meet each week and to focus on continuous improvement.

Anonymous surveys have been conducted for the first three classes. Ninety-six per cent of the participants rated their satisfaction with the training very high. Some of the anonymous comments were:

• Learning how to deal with people, change, and working together as a team was very valuable to me.

• Learning how to work together to accomplish goals on my job was very helpful;

• Learning to take a leadership role and solve problems was a very good experience; and

• I felt the class was very comprehensive in relationship to leadership.

All participants responded that they would like to have more training in a variety of work areas.

HiP will continue to train small groups (eight to ten people) of employees over the next eighteen months until all employees have been exposed to the leadership principles mentioned above. The management team favours smaller groups for training to facilitate good discussion and individual coaching.

One of the best ways to judge the success of this investment are the following comments from participants of the programme:

• “This is an investment worth making for HiP. If you limit your company’s training, you limit your company’s growth. I’ve acquired reassurance and quality knowledge needed to address current situations with employees,” says Mark Kaiser, second shift, supervisor/machinist, nineteen years of service;

• “I like it that the company has let us all know that our opinion matters,” says Seamus Louis, sales engineer; and

• “I had reservations when I first started the programme, but midway through I found the information interesting. I really found goal setting to be helpful both personally and professionally,” says Donald Glover, machinist, nine years of service.

HiP, celebrating 60 years in business this year, has a solid beginning to a bold experiment. President Loper’s goal of creating a new climate at HiP is well on its way to completion. Employees are learning to be leaders and take responsibility for their jobs, and creating customer value is the focus. Lifelong learning, continuous improvement, and individual leadership are processes that will make American manufacturing successful. The process has begun and will continue into the future at HiP.

-(3).jpg)