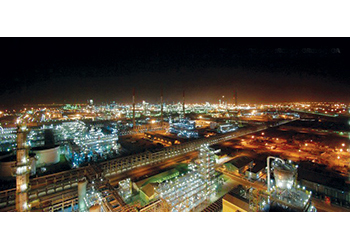

Wasit Gas Plant is one of the largest gas plants Saudi Aramco has ever built

Harnessing the power of natural gas allows Aramco to save crude oil for higher value uses, grow its chemicals business, and increase the use of this cleaner-burning fuel source in the kingdom’s energy mix.

Wasit Gas Plant is one of the largest gas plants the firm has ever built, and was brought onstream in October 2015. It was designed to process solely non-associated gas and it reached full operating capacity in mid-2016.

Adding Wasit to its portfolio represents a significant increase in Aramco’s gas processing capacity. The project reflects its commitment to increasing supplies of cleaner-burning natural gas, reduce emissions, support new industries, and free up more crude oil for value-added refining and export.

VISION FOR DEVELOPMENT

A significant portion of Aramco’s business portfolio centres on crude oil and its many uses. However, natural gas is an increasingly important product for power generation and encouraging industrial development in the kingdom.

Wasit allowed Aramco to take a significant step forward in its ability to develop and supply a much sought-after product in its local market.

The Wasit programme inspired a wide range of innovative solutions. To accelerate the project development cycle, Aramco made the most of its Event Solution Centre, bringing together multidisciplinary experts to develop unique strategies for the project.

This integrated model resulted in streamlined work processes and technologies, while ongoing assessments gave our project managers more clarity, saving time and costs.

Another outcome was the deployment of ‘big bore’ well completions - high-capacity wells, capable of producing gas at very high rates. This tactic significantly reduces the cost of production and gives it greater flexibility to meet demand.

Aramco chose a site close to Jubail to be in easy reach of existing infrastructure, as well as other related projects, such as the Fadhili Gas Plant and the railroad project connecting Ma’aden to Ras Al-Khair.

The Wasit project team could therefore control costs and increase efficiencies. For example essential utilities, such as electricity and water, were already available at Jubail and nearby Khursaniyah. Access roads from the Dhahran-Khafji Highway could also be readily extended to the site.

Today, much of Aramco’s nonassociated gas comes from offshore fields such as Hasbah and Arabiyah, so positioning the plant next to the coast was also a priority.

“We started this project from scratch. The entire area was a desert, but we managed to turn it into busy work fields,” says Fahad F. Al-Rashid, in charge of completing the mechanical works of the project.

Wasit is part of the Master Gas System (MGS), a kingdom-wide gas gathering, processing, and distribution infrastructure network. Gas produced at Wasit, travels through the MGS to reach its customers in different locations throughout Saudi Arabia.

Aramco began building the MGS in the 1970s to capture gas and use it as a new source of energy to fuel the fast-growing industrial sector, while setting the stage for greater up and downstream integration.

As all of its oil and gas producing infrastructure resides within the Kingdom of Saudi Arabia, the MGS created a unique source of competitive advantage.

To accommodate growing domestic demand, Aramco is expanding the capacity of the MGS. Phase I of the expansion project was completed in January 2018, adding 1 billion scfd of capacity, raising the total capacity of the MGS to 9.6 billion scfd. The expanded system delivers increased supplies of natural gas to customers in the King Abdullah Economic City and the Rabigh area in the Western region.

Phase II of the expansion project is designed to raise capacity to 12.5 billion scfd. When complete, Phases I and II are planned to add more than 1,600 km of pipelines to the system.

Wasit’s design reflects our plan to become self-sufficient in power generation. By converting waste heat to steam, Wasit can generate enough energy to satisfy the plant’s needs and still export power for use at other Saudi Aramco plants.

This process, known as cogeneration, allows Aramco to produce electricity as a natural byproduct of our operations. Cogeneration means less fuel is needed to produce energy, enabling it to reduce its emissions.

Behind the power of cogeneration is the power of people. More than 400 employees led the design and construction of the Wasit Gas Plant and its cogeneration facilities, many of whom were young graduates of Aramco’s apprenticeship programme.

This young team shouldered a big responsibility, as the cogeneration plant had to deliver power and steam to support the commissioning activities preparing for Wasit.

Aramco aims to source as many goods and services as possible from local businesses for its construction projects. Approximately 40 per cent of Wasit’s materials were bought and manufactured locally, advancing the diversification of the kingdom’s economy and creating employment opportunities for Saudis in manufacturing plants.

Wasit, together with our Midyan, and Fadhili gas plants, will create opportunities for a wide variety of Saudi industries, such as steel, aluminium, petrochemicals, water desalination, and electricity production. It will also enable downstream value-added industries to produce antifreeze, solvent, fuels, and other advanced materials.

The combination of these delivers on Aramco’s commitment to encouraging progress and prosperity, safely and sustainably.