Mutlaq H Al-Morished

Mutlaq H Al-Morished

The Titanium Sponge project in Yanbu is a joint venture between AMIC (Advanced Metal Industries Cluster) which owns 65 per cent and the Japanese Toho Titanium Company Limited that has an equity stake of 35 per cent

Saudi Arabia’s National Industrialisation Company (Tasnee) plans to expand into titanium manufacturing, soon after its Sponge Plant starts operations later this year.

The Titanium Sponge project in Yanbu is a joint venture between AMIC (Advanced Metal Industries Cluster) which owns 65 per cent and the Japanese Toho Titanium Company Limited that has an equity stake of 35 per cent. AMIC is 89.5 per cent directly and indirectly owned by Tasnee.

“We started on the Titanium Sponge project in February 2016 and expect it to be completed in the second half of 2019, producing 15,600 tonnes annually of titanium sponge mainly used in aviation, space, sports and medical industries and 3D printing powders,” says Tasnee CEO Mutlaq H Al-Morished in an exclusive interview with OGN.

Tasnee’s Taldeen Plastics Solutions Company has developed one of the first plastic pallets to replace wood, which will preserve the environment and relieve the pressure on natural resources.

“Plastic is inert and recyclable. Our current capacity stands at 1.5 million units a year, and we will expand according to demand dynamics,” says Al-Morished.

Excerpts from the interview:

What part does Tasnee play in Saudi Arabia’s industrialisation, which is one of the focus areas of Vision 2030?

Tasnee is one of the leading industrial companies in Saudi Arabia and the Middle East. It was established in 1985 adopting industrialisation as the best way forward for diversifying and developing the national industrial base. Tasnee took this bold initiative way back in 1985. Tasnee focused first on downstream industries before it was allowed among other private companies to invest in petrochemicals. Tasnee intends to play a prominent role in supporting the Saudi Vision 2030 by diversification into the downstream industry clusters like mining and metallurgy projects and adding value by developing the local content.

Tasnee’s major activities being investing in the industrial field and transferring advanced industrial technology to Saudi Arabia, how much have you invested so far in the industrial sector? What is the investment plan for the current year? How many advanced technologies have you transferred to Saudi Arabia so far? Which are the key ones?

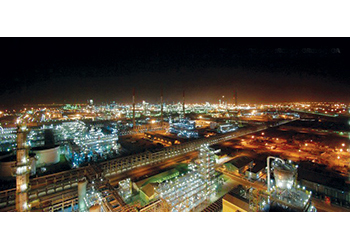

Tasnee petrochemials Complex in Jubail, Saudi Arabia

In the petrochemical sector, Tasnee collaborated with BASF (later on the share transferred to LyondellBasell) to establish the Saudi Polyolefins Company in 2001 to produce polypropylene and the Saudi Ethylene and Polyethylene company in 2006 to produce HDPE and LDPE. In addition Tasnee partnered with Evonik to establish the Saudi Acrylic Polymers Company to produce super absorbent polymers. One of the latest technology transfers by Tasnee is its partnership with the Japanese Toho Chemicals Company to establish ATTM in 2016 to produce Titanium Sponge.

Additionally, Tasnee has established its Plastic Applications Development Center in Jubail to provide technical support for production and marketing activities and to develop new products and technologies. Last year National Technology Company (NNTC) was established as a specialised and independent company to market the technical services, providing technology and expertise, and troubleshooting of production problems in addition to developing new products.

Having made a net profit of SR1.2 billion last year and also achieved a revenue increase of 6 per cent, what are Tasnee’s profit and revenue targets this year? How do you see prospects for your company over the coming year?

Tasnee has overcome difficult financial situation with a successfully executed restructuring programme and strategy. This helped Tasnee to improve its operating performance, boost sales volumes and cut general and administrative costs, turning from a significant loss in 2015 back to profitability starting from 2016. We still have certain financial targets to accomplish in a sustainable manner and going forward focus on growth strategies. The environment is very competitive especially with shale gas developments as well as international tariffs regime and economic uncertainties which currently prevail. We are aware of these challenges, but we can’t control, impact, or even predict. However, we still can improve our performance, decrease our operating costs, increase our production to the maximum, improve our products’ quality, try to expand domestically or internationally, and be ready to embrace market dynamics. All these objectives stated should only strengthen our positioning in the market to face competition and enhance sustainable profitability.

How much worth of projects are you executing currently? When did you start work on them and when will you complete your order? Could you give us details of work carried out recently?

Currently we are working on two main mega projects – The first one is the Titanium Sponge project in Yanbu which is a joint venture between AMIC (Advanced Metal Industries Cluster) that owns 65 per cent and the Japanese Toho Titanium Company Limited having an equity stake of 35 per cent. AMIC is 89.5 per cent directly and indirectly owned by Tasnee. We started on the Titanium Sponge project in February 2016 and expect it to be completed in the second half of 2019 - producing 15,600 tonnes annually of titanium sponge mainly used in aviation, space, sports and medical industries and 3D printing powders.

The second project is the Titanium Ilmenite Smelter, which is 89.5 per cent directly and indirectly owned by Tasnee, producing 500,000 tonnes of high grade Titanium feedstock and 235,000 tonnes of pig iron. The project started in 2013. The smelter being the largest of its kind and using a new technology in the field has faced some technical issues. Now we are working together with our partner “Tronox” under a technical services agreement and the technology provider to overcome those problems and re-start the first furnace in the next six months. Also, the second furnace is intended to be commissioned (after completion of the commercial production of Furnace 1).

What are your petrochemicals production targets this year? How do you manage to excel despite there being other petchem players in the kingdom offering stiff competition?

In 2018 our petrochemical sector contributed significantly to the sustainability of our growth achieving a number of successes in terms of safety, environment-friendliness, operational efficiency, increased production, quality standards, increased sales and localisation of jobs. Most of our production plants in the Tasnee petrochemical complex worked at the maximum production capacity with high production levels while maintaining the highest occupational safety standards. We always target excellence in operational performance, production, quality and safety standards - all at the same time, benefiting from the advantages we have and trying to do the very best on all fronts to maximise our profitability.

Referring to competition, it is not a local competition but it is mainly an international competition to all of us in Saudi Arabia and even in Gulf area. Locally, we have the same advantages and face the same challenges, like the increased price of ethane and methane, losing some of the significant advantage we used to have over others. Now we are almost at par compared to the shale gas situation in the US and to China’s coal chemical Industry. Both the US and China producers have the advantage of good feedstock and access to big markets. We have the advantage of good feedstocks, but not market access. On the contrary, we are facing the additional shipping cost which adds to our cost base with logistics and market access.

With Tronox having completed its acquisition of the titanium dioxide (TiO2) business of The National Titanium Dioxide Company Limited (Cristal), what more developments do you see for Tasnee’s Titanium business? Do you think that you are on a stable wicket?

After the Tronox deal, we are still a large investor in Titanium Dioxide in the world, currently with an equity stake of 26 per cent in the new enlarged Tronox, a much bigger combined entity of global scale. It is a ‘win-win’ deal. Tronox is big in the mining of Ilmenite, Rutile, and Zircon. By merging the two businesses we shall accomplish synergies within the downstream and upstream spectrums in a fully integrated manner. Another significant benefit for both companies is that we use a superior chloride-based technology in the world. Normally, combining technologies of two big companies can be complicated. However, as we are both chloride-based we have great synergy together. Our combined global footprint is now second to none in the world. We are now all over the globe in US, UK, Australia, South Africa, China, The Netherlands, France, and Brazil.

What were the various developments within the company over the past year? For example, have you added new products, expanded into any new area of activity?

In our Taldeen Plastics Solutions Company, which is embedded in our Downstream Strategic Business Unit, we have developed one of the first plastic pallets to replace wood, which will preserve the environment and relieve the pressure on natural resources. Plastic is inert and recyclable. Our current capacity stands at 1.5 million units a year, and we will expand according to demand dynamics. We are also the largest pipe-making facility in the world, with diameters up to 3 metres. Taldeen also started production in most of its plants there to provide a varied portfolio of products including water, handling, pipes s and agricultural solutions.

Also, we are considering expanding into titanium manufacturing, as the Sponge Plant starts its operations. Titanium manufacturing is a speciality industry. Furthermore, we are focusing on growing our petrochemical business in the near future. Our NIPRAS company is developing a very important soil enhancer (DIBAL) which is currently expected to transfer from pilot plant to commercial scale.