NETZSCH NEMO Multiphase pump testing

NETZSCH NEMO Multiphase pump testing

NETZSCH Pumps and Systems, experts in solutions designed specifically for difficult pumping applications, extends its range of NEMO API progressing cavity pumps and NOTOS Multi Screw pumps in the Oil & Gas sector.

The company, which has a major presence in Saudi Arabia and the region, is continuously expanding its products’ range and also its global network. It recently opened new branch offices in Romania, Vietnam and Columbia and also new service centers in Australia, especially providing technical support to the oil and gas industry, says Ulrich Eibl, Global Business Field Manager Oil & Gas for Germany-based NETZSCH.

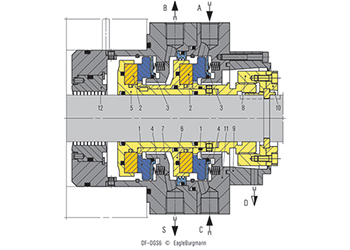

On the product side, NETZSCH has launched a specialised API pump in the region which reduces lead times by up to 50 per cent. The cast design means less risk during manufacturing and less efforts for NDT, to issue documentation and also for document control on the customer side. Additionally the NOTOS Multi Screw Pump range is being continuously extended, using which flow rates of up to 550,000 barrels per day and pressures of up to 1200psi can be achieved, he explains.

NETZSCH delivered its first pumps to Saudi Aramco more than 20 years ago. Besides pumps directly delivered to Saudi Aramco, many pumps have been provided through various business partners and joint ventures to clients such as Sabic, Sumed, KJO (Al Khafji Joint Operations), Marafiq and many others, he points out.

Over the years more than 100 large pumps have been delivered to installations at offshore fields such as Khafji and Hout and onshore gas plants like the Fadhili and Wasit and to refineries and petrochemical plants such as Yanbu, Rabigh, Jazan and others.

The company is currently executing several projects for well-known oil and gas firms in the Gulf countries, which are either under manufacturing, delivery or commissioning. The most prestigious one is the commissioning of the biggest progressing cavity pumps which were ever built. Eight identical pumps are about to be set in operation in a neighboring country, transferring more than 450,000 barrels of crude oil per day.

NETZSCH not only provides pumps as a single product but also offers a comprehensive service around it including documentation and testing.

Eibl says the challenge to work with an organisation like Saudi Aramco is to deal with the high assessment requirements set for their partners. To fulfil these requirements NETZSCH not only provides certified product quality based on high production depth and well educated, skilled workers including in-house Level 3 FROSIO coating inspectors, in-house ASME Level 3 NDT inspectors, WPQR for special materials such as Duplex, Super Duplex up to Titanium and welding facilities according to ISO 3834 among others but also a high expertise in the Oil & Gas Business Field, set up a decade ago to gather industry experts in the sales force.

One major USP (unique selling proposition) which sets NETZSCH apart from many others is its global presence and on-site support, made possible through its own world-wide network of sales and service organisations, many years of experience in the oil and gas industry even in the most challenging applications whether it is upstream, midstream or downstream.

NETZSCH is second to none in its ability to read and interpret complex specifications and provide customised solutions and it has its own global business field organisation and project department for the handling of large and complex projects.

Talking about business prospects, he says it is positive in general as long as the oil price is stable at about 50USD/bbl or above. Certain countries are strongly influenced by political developments which can have either a negative or positive impact.

The oil and gas business has recovered after the oil price crisis. Increasing investments in the industry are reflected in increasing order intake, he adds.