Chemistry expertise is crucial to the success of the carbon capture process design

Chemistry expertise is crucial to the success of the carbon capture process design

Vineeth Ram from OLI Systems tells OGN about how their latest investments in developing new chemistries and capabilities will help improve operations efficiency and environmental sustainability in O&G

For the last five decades, OLI Systems’ skilled subject matter experts have drawn upon their deep industry-specific domain expertise to deliver a portfolio of electrolyte modeling software solutions and consulting services.

These services and solutions have established OLI as a trusted advisor for a complex range of industrial water chemistry applications.

Over five hundred global clients use OLI’s solutions to design and operate industrial equipment and processes, more efficiently and effectively.

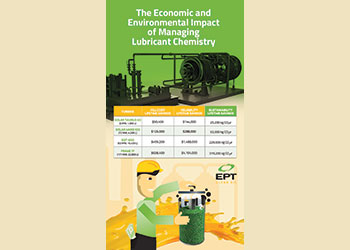

By using OLI’s solutions, operators and their service providers can optimise materials selection, improve equipment reliability, enhance environmental sustainability, and minimise operations risk.

OLI understands the ongoing difficulties that oil and gas service companies and operators encounter daily.

The increasing need to improve operational efficiencies and drive improved environmental sustainability across the industry brings its own set of challenges.

These challenges require OLI to continuously enhance its predictive insights in water chemistry applications.

|

Mineral scaling can hinder fluid flow and jeopardise upstream production |

OLI’s team of expert chemists and application engineers continually research and invest significant resources to help the industry to predict phenomena such as corrosion, scaling, fouling, chemical equilibria, phase changes and toxic contamination.

In the last three decades alone OLI has invested more than $150 million, in a demonstration of its deep, long-term commitment to technological innovation.

With this investment, OLI is positioned as the primary software solution provider that offers first-principles based, highly accurate thermodynamic and kinetic electrolyte-focused modeling to address a broad range of complex challenges across multiple different operating conditions.

The latest round of innovations is captured in the most recent release of the OLI Platform v11.5. New chemistries and capabilities have been added to OLI Studio, OLI Flowsheet: ESP and OLI Alliance Engine.

ANALYSE MINERAL SCALING RISK AND OPTIMISE CHEMICAL TREATMENT

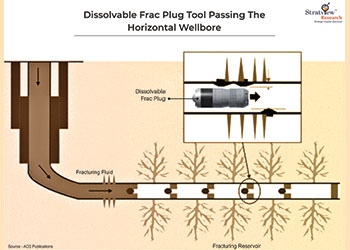

The formation of mineral scaling can hinder fluid flow and jeopardise upstream production, causing production losses and inability to meet demand, resulting in higher operations costs.

V11.5 includes new chemistries to predict nucleation of calcite, barite, gypsum and celestite, the most common mineral scales.

The nucleation model accurately calculates the induction time for these minerals in the presence or absence of common chemical inhibitors in brine to help analyse scaling risks in upstream production and wastewater treatment.

Five new scale inhibitor (DTPMP, EDTMP, PBTC, MLA, PMLA) chemistries and kinetics with the common scaling minerals are included in the v11.5.

These capabilities help to evaluate how scaling can be prevented with the minimal use of chemical inhibitors, helping to optimise chemical treatment programs and accelerate operations efficiency in oil and gas production and water/wastewater treatment.

MORE RELIABLE CO2 TRANSPORT, CAPTURE AND STORAGE

Globally, countries are aiming for net-zero greenhouse gases by 2050. Carbon capture, utilisation, and supply (CCUS) is one of the most practical solutions available for large-scale emissions reductions.

The development of CO2 transport and storage networks for industrial CCUS is now being supported by governments and happening at scale in many parts of the world.

Effective process design requires domain expertise along with a sound technical understanding of the chemistry, not only to design and operate but also optimise and troubleshoot operations.

The insight gained in examining behaviour like CO2 solubility and other acid gases in water as temperature, pressure, and composition change, especially in extreme conditions is essential.

OLI’s continued investment in R&D has allowed it to improve its capabilities in a wide range of chemistries.

A key focus of OLI’s innovation in v11.5 has been on addressing the complicated issues that surround CCUS.

The v11.5 is the only simulation software in the market that can successfully predict corrosion behavior in pipelines and storage containers that transport CO2.

Corrosion in CO2 transport: A key challenge with CO2 transport in carbon steel pipelines and storage containers is corrosion due to impurities trapped in the CO2. These impurities, when in contact with each other react to form highly corrosive acids.

Since carbon steel is the most cost-efficient material for CO2 pipelines, mitigating risk requires the management of impurities within safe limits in dense flow conditions.

OLI’s unique simulation capabilities have been significantly expanded in v11.5, providing state-of-the-art predictions of corrosion and solids formation that significantly impact equipment reliability during CO2 transportation.

Four new categories of CO2 transportation chemistries enable the prediction of the formation of nitric and sulfuric acid, which are extremely corrosive to carbon steel.

This allows for accurate risk assessments in pipelines as well as optimal materials selection that makes CO2 transportation and storage safe and reliable for the oil and gas and power generation industries.

The new and unique sulphuric and nitric acid chemistries and additional carbonyl sulfide, ammonia, and acetaldehyde chemistries, accurately predict the potential of pipe failure in CO2 transportation by modeling the impact of SOx, NOx and other impurities on corrosion and solids formation.

Design of novel CO2 capture processes: CO2 capture process design and operations continues to be a major challenge in the future economics and sustainability of CCUS.

OLI has devoted considerable research and development on improving the efficiency of innovative and CO2 capture processes such as the mixed salt process which are more sustainable compared to the existing processes.

The new mixed salt plus amine system – a combination of ammonia, potassium carbonate and MDEA - chemistry models CO2 capture with existing unit operations that enhance cost effectiveness, and is unique to OLI’s software.

Only OLI has the combination of ammonia, CO2, and urea chemistries to accurately model the CO2 partitioning to the vapour phase and other non-aqueous liquids, as a function of temperature, pressure, and acid concentrations, to effectively capture CO2.

The ammonia/sodium hydroxide amine solvent in v11.5 provides accurate predictions of the solubility of ammonia in caustic solutions helping to enhance process design

OLI EXPERTISE IN CCUS PROCESS DESIGN

Chemistry expertise is crucial to the success of the carbon capture process design due to the multifaceted nature of the practice.

Complex chemical behaviour of multi-component chemical systems and their associated process flow are often unpredictable leading to unreliable, hazardous, and costly operations.

Along with the development of new chemistries available in v11.5, OLI has created a team of expert consultants in thermophysical modeling, process simulation and domain understanding to develop custom models of capture processes for design, optimise materials selection, improve asset integrity, and maximise operational efficiency.

ENHANCED CORROSION PREDICTION

Further R&D has resulted in the expansion of the existing iron oxide and hydroxide chemistries in this release, which enables the accurate prediction of iron chemistry in steam generating plants to prevent flow accelerated corrosion (FAC) of carbon steel.

Updates to the nitric acid chemistries enable better prediction of thermophysical properties of this important chemical.

V11.5 also includes updates to the corrosion rate predictions for Alloy 304 in water, a unique capability of OLI.

Also, new boron chemistry and related lithium hydroxide chemistry improvements deliver more accurate corrosion predictions in nuclear energy reactors.

SOFTWARE ENHANCEMENTS

This release updates OLI Studio, OLI Flowsheet: ESP and OLI Alliance Engine Windows editions to operate in 64-bit, resulting in an increased performance when executing calculations.

The default thermodynamic framework for OLI Studio and OLI Flowsheet: ESP has also been set to MSE framework which delivers improved simulations.

ACCELERATE DIGITAL TRANSFORMATION

The new capabilities in v11.5 can be leveraged by OLI’s Cloud Platform (Cloud APIs and Cloud AppBuilder) to expand access to all stakeholders regardless of expertise in electrolyte chemistry, these capabilities are ideal for real-time monitoring and automation to improve operational performance in digital transformation projects.

OLI Systems platform v11.5 is now available to download for existing users.