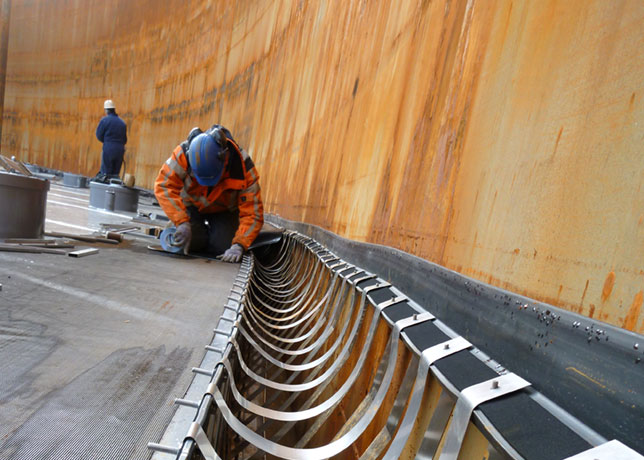

The plug-and-play capability of the iDT allows for easy deployment

The plug-and-play capability of the iDT allows for easy deployment

Interwell's innovative Iconic Digital Transponder revolutionised well operations by providing real-time, accurate downhole pressure and temperature data, eliminating unnecessary rigging, cutting costs, and marking a Middle East first

A major operator in Qatar required real-time pressure monitoring below the back pressure valve (BPV) in a closed well with no perforations while rigging up coiled tubing.

The operation’s success depended on precise, live data to avoid unnecessary rigging of PCE, which would save rig time and reduce costs.

Traditional monitoring methods were insufficient, and the client needed a solution that could provide accurate, real-time insights without disrupting the operation’s timeline or budget.

SOLUTION

To address this challenge, Interwell deployed the Iconic Digital Transponder (iDT), a state-of-the-art acoustic downhole monitoring system featuring two-way communication and a plug-and-play design.

|

Interwell's iDT is a state-of-the-art acoustic downhole monitoring system |

This marked the first use of the tool in the Middle East.

The system was quickly integrated into the operation, providing continuous, real-time monitoring of pressure and temperature below the BPV.

This real-time insight confirmed that there was no pressure below the BPV, negating the need to rig up PCE and ensuring the operation proceeded without delays or additional rig time.

The plug-and-play capability of the iDT meant it was easily deployed, minimising downtime and ensuring seamless operations.

Interwell’s exemplary support also ensured the data was accurately interpreted and that the client was continuously informed. This innovative approach not only addressed the immediate challenge but also demonstrated the potential for future applications in similar scenarios.

VALUE CREATED

The implementation of the iDT delivered significant value to the customer. By confirming that there was no pressure below the BPV, the tool eliminated the need to rig up PCE, directly saving the client considerable time and costs.

|

The real-time monitoring capability of the iDT delivers significant value to customers |

The real-time monitoring capability ensured that the operation proceeded without delays, reducing the overall rig time and enhancing operational efficiency.

The customer can now rely on this innovative technology for similar challenges, confident in its ability to deliver precise, real-time data and significant cost savings.

Moreover, the successful deployment of this technology in Qatar marked a milestone as the first of its kind in the Middle East.

It demonstrated the potential of acoustic downhole monitoring systems to revolutionise well management practices, particularly in complex well operations.