Abdulaziz Alsuayyid

Abdulaziz Alsuayyid

A paper by Aramco staff highlights the advantages of the Partial Mechanical Completion (PMC) process, including accelerated delivery, schedule flexibility, and operational readiness, while also acknowledging its potential challenges

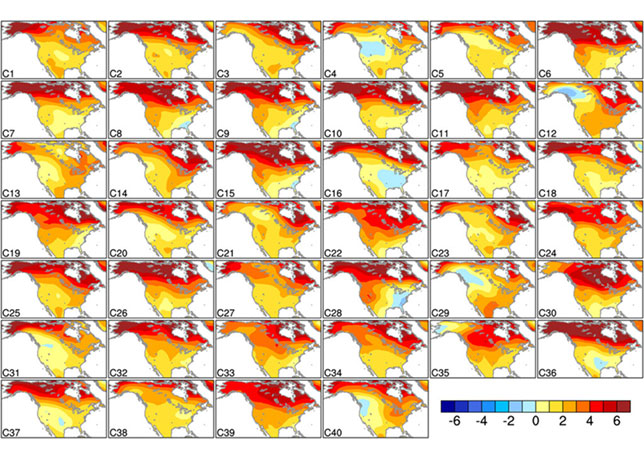

Partial Mechanical Completion (PMC) is a method for delivering mega projects in phases (Figure 1) that allows the execution agency to hand over each phase to the end-user after completing construction, testing, and pre-commissioning for that phase. The critical and common systems of the facility, including their isolation boundaries, are a key consideration, says Abdulaziz Alsuayyid and Abdullah Alghamdi, Project Engineers, NGL Recovery and Fractionation Division, Tanajib Gas Plant Program Department, Saudi Aramco, in a paper, entitled ‘Projects Delivery with Partial Mechanical Completion Approach.

Constructability follows in defining system boundaries, with geographical location and system layout also being important.

|

Abdullah Alghamdi |

PMC is effective for managing risks and opportunities in large projects, particularly with multiple interface points between various agencies or operational facilities.

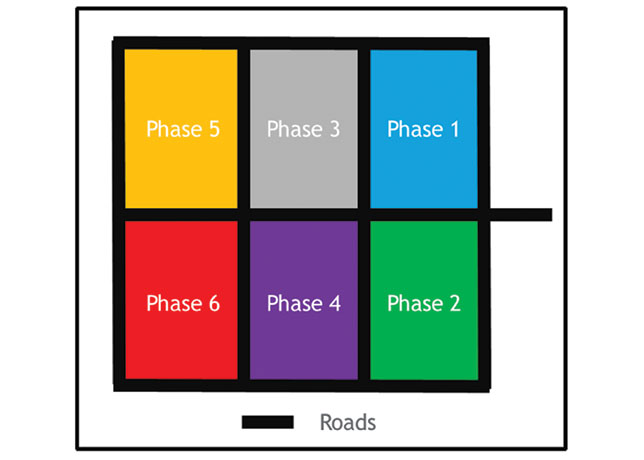

The PMC approach is adopted during the project planning phase (Figure 2) and continues through the project lifecycle, including execution (engineering, procurement, construction), monitoring, controlling, and close-out (handover and acceptance of PMC). To implement this, facility systems boundaries must be defined, phases agreed upon with stakeholders, and contents of each phase determined. The project team must consider stakeholder agreements and the PMC approach while developing the project schedule and activity sequence. Clear criteria, procedures, roles, and responsibilities must be established to ensure the applicability of Partial Mechanical Completion and manage the handover process effectively.

EXECUTION

As plans were set towards PMC approach such as project execution plan and project schedule, the execution shall leverage the partial handover approach, through the typical mega project Engineering, Procurement and Construction (EPC), focusing on the following items through each step:

• Detailed design for PMC: Defining boundaries and interfaces for the mechanical system is crucial for Partial Mechanical Completion (PMC). This involves identifying the equipment, components, and interconnections included in the handover, supported by clear drawings and schematics.

The commissioning team’s expertise is essential in identifying areas for improvement, optimizing processes, and determining key isolation points and interfaces. This ensures effective independent testing and commissioning of the PMC-eligible portions and is vital during the development of production processes.

|

Figure 1 ... PMC allows delivery of mega projects in mutiple phases |

Safety considerations for PMC must be addressed by incorporating robust isolation and lockout/tagout provisions for safe isolation and energization of systems. Activities should be managed under Simultaneous Operations (SIMOP), which oversees concurrent construction, testing, and commissioning activities within overlapping construction areas and live facilities to ensure safe and seamless execution.

Effective PMC requires comprehensive documentation and record-keeping. Establishing standardised templates, checklists, and utilising digital platforms with search engine support is essential for tracking and managing project documentation. This documentation process must adhere to project quality requirements throughout the project lifecycle.

• Procure for PMC: Develop detailed delivery and installation schedules during planning, synchronized with PMC milestones, to ensure timely availability of equipment and materials. Prioritize vendors based on experience, capacity, timely delivery records, and alignment with PMC needs. Evaluate their ability to meet PMC objectives and collaborate effectively. Leverage procurement tagging to support monitoring and expedite delivery processes by aligning bulk-procured materials with engineering drawings, enhancing the efficiency of PMC phases.

• Construct for PMC: Regularly reviewing and updating the construction schedule is crucial for tracking PMC-related activities and addressing conflicts or delays. Effective scheduling and coordination provide visibility into PMC progress, enabling proactive decision-making and timely mitigating actions.

During construction, adherence to organizational and international standards is vital. Detailed inspection and testing plans must be developed to ensure activities are completed correctly and on schedule, minimising rework.

Clear communication and collaboration are essential for PMC. Establish defined channels and reporting structures between the construction team and other project stakeholders. Roles, responsibilities, and decision-making authorities should be clear, with regular meetings and updates to maintain alignment and address issues proactively.

|

Figure 2 ... the various phases of the PMC |

Logistics should facilitate smooth PMC execution. Design site layouts and access routes to optimize material handling and movement. Include strategically placed lay-down areas, storage, and equipment staging zones. Implement traffic management plans to manage construction traffic after partial facility handover and within the operating facility, ensuring safety with temporary fencing as required.

MONITORING & CONTROLLING

Monitoring and controlling focus on progress and quality, which must be continuously tracked throughout the project lifecycle. Conduct detailed progress review meetings weekly, using reports to monitor performance. Key performance indicators (KPIs) with predefined thresholds and triggers, as outlined in the risk assessment report, help manage progress and quality for PMC interests. Project team adaptability and schedule flexibility are crucial for successful phase handovers. This may require frequent reallocation of manpower and resources to address changes as per risk responses.

HANDOVER & ACCEPTANCE OF PMC

The handover stage, integral to the project lifecycle, must adhere to a fixed schedule aligned with the overall project timeline to fully leverage the PMC approach and avoid delays.

Acceptance criteria are crucial during close-out, requiring clear, agreed-upon terms among stakeholders to meet end-user expectations and ensure a smooth handover. Stakeholders should use checklists, site visit assessments, and quality document verification to confirm completion of all construction and pre-commissioning activities.

The handover package must include all necessary drawings, procedures, test results, special acceptance approvals, and warranties for future maintenance or upgrades. Clearly defined roles and responsibilities, along with planned communication channels, are essential for addressing clarification requests before and during the sign-off stage.

PMC ADVANTAGES

• It allows for an early startup due to the progressive completion and handover of the project, leading to project duration enhancement.

• Schedule flexibility, as the resources can be allocated based on the magnitude of the activity due to the parallel execution.

• As the learning curve develops with each phase, it improves productivity, minimises the need for rework and ultimately reduces the overall project cost.

• Promotes an early startup to accelerate the timeline and enable quicker revenue generation for the end-user organization.

CHALLENGES & CONSIDERATIONS

• A detailed SIMOP document needs to be developed and reviewed by all stockholders to maintain a safe environment at the construction site adjacent to the handover phase.

• The project team needs to develop a detailed stakeholder management plan that outlines the communication strategies and engagement mechanisms for all key stakeholders involved in the PMC process.

• The project team must proactively engage with all relevant stakeholders to ensure alignment, transparency, and collaboration during the execution of PMC activities.

• Define boundaries, systems and subsystems of each phase that will be handed over to the end-user along with the acceptance criteria.

• Engineering documents need to be issued in a sequence that serves the PMC approach, which is ready for construction (IFCs) and free of holds to avoid modification and rework.

• Conducting a frequent meeting with material suppliers to ensure on time delivery of the material delivery time for each phase.

• Maintain document control process for a smooth handover of procurement, engineering and quality documentation for the end-user records.

• To have a record of lessons learned, which will aid in improving the learning curve for the upcoming phases.

REFERENCES

• Ramanathan, K., & Varma, A. (2019). Partial Mechanical Completion (PMC) - A Strategy for Faster Project Delivery. International Journal of Engineering Research and Technology.

• Memon, A. H., Rahman, I. A., Abdullah, M. R., & Azis, A. A. A. (2014). Factors affecting construction cost performance in project management projects: Case of MARA large projects. International Journal of Civil Engineering and Built Environment.

• Nandurkar, P., & Patil, V. (2022). Partial Mechanical Completion (PMC) - A Paradigm Shift in Project Delivery. International Journal of Engineering Research and Technology.

• The Molenaar et al. (1999).

This is an edited version of the original paper, which can be read online: www.ognnews.com