Jason Villarreal

Jason Villarreal

Asset performance management is optimising operations within the Middle East’s energy sector by enhancing operational efficiency, reducing downtime, and achieving sustainability goals through advanced data analytics and proactive maintenance strategies, Jason Villarreal, Director of Product Marketing, AspenTech, tells OGN

In today’s rapidly evolving industrial landscape, asset-intensive companies face many challenges in maintaining operational efficiency and reliability.

The Middle East, renowned for its thriving energy sector, is no stranger to these challenges.

From ensuring the uptime of critical machinery to optimising maintenance schedules, companies in the region are constantly seeking solutions to enhance their asset performance while minimising costs and mitigating risks.

This is where asset performance management (APM) emerges as a game-changer.

BALANCING EFFICIENCY, RELIABILITY, AND SUSTAINABILITY IN ASSET-INTENSIVE INDUSTRIES

Asset-intensive industries such as refineries, chemical plants, power generation, mining, and mineral processing facilities rely heavily on complex machinery and equipment to drive their operations.

However, ensuring these assets’ optimal performance and reliability throughout their lifecycle while maintaining a commitment to sustainability poses a significant challenge.

Frequent breakdowns, unexpected downtime, and inefficient maintenance practices disrupt operations, incur substantial costs, and pose safety risks.

Moreover, in an era where environmental stewardship is paramount, companies must find ways to minimise their carbon footprint and reduce resource consumption while maximising operational efficiency.

INTRODUCING ASSET PERFORMANCE MANAGEMENT

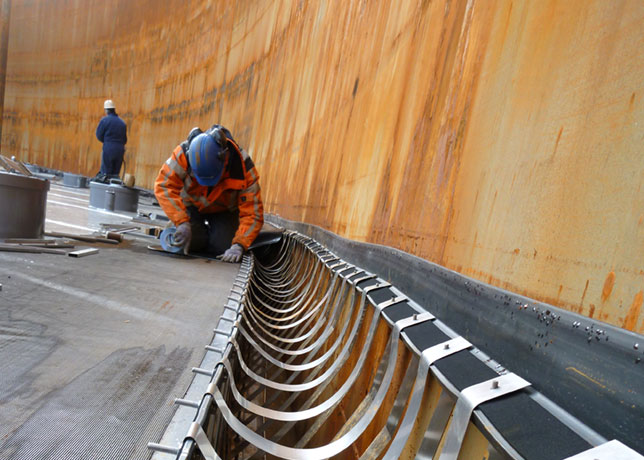

|

Optimal asset performance while maintaining sustainability is a significant challenge for plants |

APM refers to a strategic approach focused on optimising the performance, reliability, and availability of physical assets throughout their lifecycle.

APM aggregates data from diverse sources, including sensors, yield metrics and product quality parameters, and applies advanced analytics to evaluate risks, improve asset and process health, reduce downtime, increase operational efficiency, and ensure safety and compliance.

The goal is to maximise the return on investment (ROI) of these assets while ensuring they operate within the desired performance parameters while minimising their environmental impact.

At its core, APM significantly aids management, maintenance, and operational processes in the following ways:

• Management: APM provides a comprehensive view of process, operations, and maintenance health across entire plant or facilities, enabling informed decision-making at the management level, and providing the insights needed for leaders to take rapid action.

It aligns the organisation’s maintenance and operational strategies with broader business goals, ensuring that asset investments are optimised for maximum return while mitigating risks.

• Maintenance: APM complements existing maintenance strategies, enabling a shift in the maintenance approach from reactive to proactive and predictive approaches.

Leveraging data and advanced analytics, it predicts equipment failures before they occur and recommends mitigation strategies.

For every mitigation option input by the user, the solution conducts a financial impact assessment, furnishing the user with informed recommendations designed to minimise disturbances to production and delivery commitments.

This foresight allows for timely intervention, minimising unplanned downtime, extending the lifespan of assets, and reducing maintenance costs. It also helps in optimising spare parts inventory, thereby reducing capital locked in unused inventory.

• Operations: APM enhances operational efficiency by continuously monitoring asset and process performance and identifying areas where performance can be optimised.

Real-time insights enable operational adjustments to ensure consistent product quality, improve process yields, or make operational adjustments to avoid equipment degradation. As a result, APM solutions improve productivity, enhance product quality, and reduce energy consumption and waste, contributing to sustainable operations.

Thus, APM can contribute to achieving the organisation’s sustainability goals by reducing energy consumption, minimising waste, and achieving environmental compliance.

APM IN ACTION

Across the Middle East, asset-intensive companies are best suited to the use of APM solutions.

Industries like oil and gas, chemicals, metals and mining, power generation and polymers are prime candidates as unexpected downtime or unplanned events can be very costly across these markets.

Additionally, discrete manufacturing sectors such as automotive, electronics and heavy machinery also benefit from APM’s ability to help maintain production assets at peak performance levels over the long-term.

For instance, OCP Ecuador utilised an APM solution to enhance the availability and reliability of pumps and generators, resulting in a 20 per cent increase in uptime and a 25 per cent reduction in maintenance expenses.

Similarly, Oryx GTL implemented an APM solution to minimise flaring and enhance yields in its fractionator, leading to notable reductions in flaring, CO2 emissions, and off-spec product.

Furthermore, a Latin American pipeline company successfully deployed APM for comprehensive system modelling and maintenance strategy assessment, safeguarding substantial value.

These examples underline the versatility and effectiveness of APM solutions across various industries, highlighting their role in improving operational efficiency and reducing costs.

A SUSTAINABLE FUTURE WITH APM

As companies in the Middle East continue to prioritise sustainability, the role of APM in driving sustainable operational practices will only grow.

With advancements in technology and analytics, APM solutions are becoming increasingly sophisticated, enabling companies to achieve new efficiency, reliability, and sustainability levels.

In conclusion, APM offers a sustainable solution to the challenges faced by asset-intensive companies in the Middle East.

By aligning operational excellence with sustainability goals, APM empowers companies to optimise asset performance, reduce environmental impact, and ensure a sustainable future for future generations.