Andrew Mogford

Andrew Mogford

With the regional refined oil products market set to grow, Nalco Water continues to bring new innovative fuel additive solutions to support customers across the region, Andrew Mogford, Regional Account Lead IMEA Downstream, tells OGN

The Middle East is flush with new refinery capacity at a time when Europe, OECD Asia and the US continue to rationalise older, less competitive capacity, often converting to biofuels.

Adding to the mix, the demand for oil products in Asia continues to increase along with the need for Europe to replace oil product flows from Russia.

Middle East refiners are perfectly positioned to pick-up this demand after having invested in the last decade and continuing to invest in new capacity through facility expansions and grassroots facility construction.

These projects not only include increasing distillation capacity but also boosting conversion capacity.

Most of the conversation capacity additions, have and will be in new desulphurisation units to produce high quality, ultra-low-sulphur (ULS) fuels for both domestic use and international markets.

|

Nalco Water has more than 55 years of experience providing over 100 approved fuel additives |

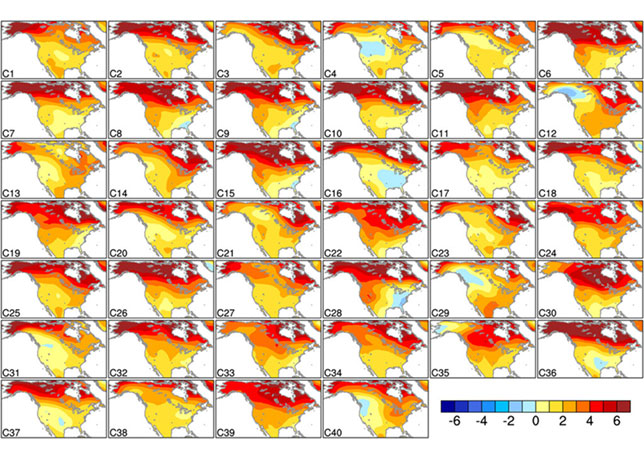

From 2024–2027, it is predicted that the Middle East will continue to increase supplies of oil products (ultra-low sulphur diesel, jet fuel/kerosene) to Europe and Asia, with the Middle East forecast to add approximately 1.6 million barrels per day (bpd)of new distillation capacity by 2027.

To supply refined oil products to Europe and Asia, Middle East refiners will need to meet market and regional product specifications.

The meeting of some product specifications (for example, diesel lubricity or jet fuel conductivity) can be achieved through chemical additive addition to the finished oil products.

Even after a finished oil product is processed, problems can arise in handling, transportation and storage but these can be corrected through chemical additives.

Chemical additives that are added to finished oil products (diesel, jet fuel, etc) must have market/industry specific approvals, obtained through rigorous laboratory and field testing of the additive to ensure there is no negative impact on the finished fuel.

|

Table 1 … Nalco Water offers a solution for every process stream through its diverse portfolio of fuel additives |

The typical additive approvals required for use in diesel are EI1535, Multi-Product Pipelines, DGMK No-Harms and Platts Listing. Meanwhile, Def Stan 91-91 approval is a typical requirement for jet fuel additives for Europe and Asia.

Finished fuel additives are available from multiple sources. As a global leader in additive products and expertise, Nalco Water maintains a diverse portfolio of fuel additives (Table 1) with the required market and industry approvals.

Fuel additives and services help the world’s refiners, terminals and traders continuously produce specification fuels safely and profitably.

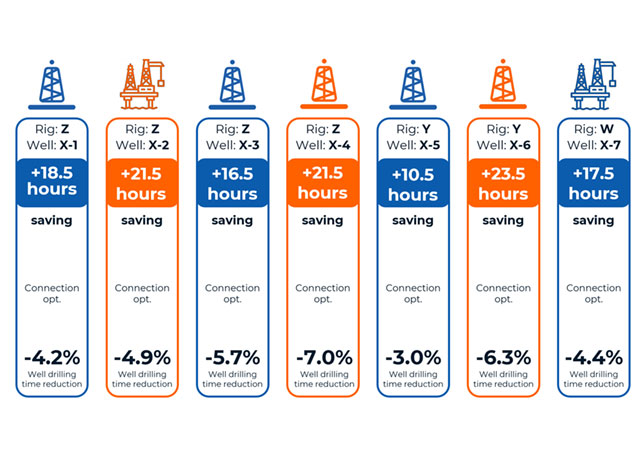

Guided by a thorough understanding of fuel specifications and testing requirements, leading companies like Nalco Water develop comprehensive fuel additive programmes that include additive selection, specialised dosing and injection equipment, safe on-site application by trained personnel and deep expertise available on-demand when needed.

|

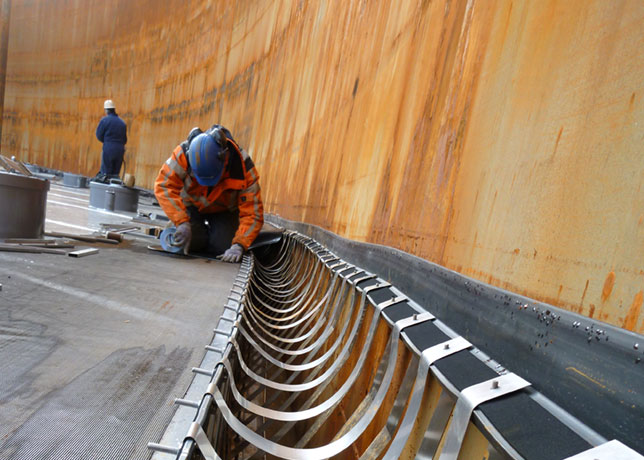

Nalco Water undertakes rigorous testing of fuel additives |

Nalco Water has over 500 sales and service personal based throughout the Middle East. With manufacturing facilities in Saudi Arabia, headquarters in the UAE and with operations throughout the Middle East (Kuwait, Oman, Qatar, Iraq, Egypt, Bahrain); Nalco Water is well position to support the Middle East refiners with their refined oil product challenges and fuel additive requirements.

As the refined oil product market in the Middle East continues to change, Nalco Water will continue to bring new innovative fuel additive solutions to support customers across the region.