Louis Pietranek ... technology focus

Louis Pietranek ... technology focus

Cutting-edge ROVs are transforming offshore work with AI, eco-friendly designs, and compact technology, enhancing efficiency, safety, and sustainability in the oil and gas industry, Louis Pietranek, Westerton Access Managing Director, tells OGN

The oil and gas industry are continuously evolving, driven by the need to balance operational efficiency, cost reduction, and regulatory compliance.

Recent advancements in robotics and manipulation systems have significantly expanded the operational potential of offshore remotely operated vehicles (ROVs).

State-of-the-art sensors and precision and agile robotic arms now allow these vehicles to undertake intricate tasks such as subsea repairs, maintenance, and even construction projects with remarkable efficiency.

As offshore operations grow in complexity, the demand for ROVs outfitted with advanced robotic technologies is escalating rapidly.

The development of sophisticated small ROV tooling extends beyond inspection capabilities, encompassing pipeline survey equipment, geoscience tools, scanning technologies, and photogrammetry.

|

Falcon ROV from Saab Seaeye |

These strides enable ROVs to replace functions traditionally performed by divers or larger work-class ROVs, minimising environmental impact and enhancing operational safety.

Conducting surveys and maintenance activities without downtime ensures continuous operations and eliminates revenue losses for offshore asset owners. As operators and asset owners increasingly utilise ROVs for subsea tasks, here are three trends helping to shape the future of offshore operations.

AI-ENABLED ROVS

The subsea ROV market is transitioning towards autonomous ROVs, driven by advanced artificial intelligence (AI) and machine learning (ML).

These technologies enable ROVs to execute complex tasks independently, significantly enhancing their operational efficiency.

Analysing vast amounts of data and adapting to changing underwater conditions in real-time, AI and ML allow ROVs (and their operators) to make better, informed decisions, improving their ability to handle dynamic subsea environments.

Going a step further, in the future AI and machine learning will allow ROVs to operate more independently and will integrate additional business intelligence systems coupled with real-time data delivery, further reducing the need for human intervention.

|

A Westerton ROV team |

This development is crucial as companies strive to maximise productivity while managing risks and expenses effectively.

Additionally, adopting autonomous ROVs facilitates more frequent inspections, allowing for proactive maintenance and early detection of potential issues.

This approach extends the lifespan of offshore assets and ensures compliance with stringent regulatory standards.

ENVIRONMENTALLY CONSCIOUS ROVS

As the global focus on sustainability intensifies, and governments worldwide are implementing stricter environmental regulations, the development of ROVs with minimal environmental impact is gaining substantial momentum.

This involves the use of eco-friendly materials and strict adherence to environmental regulations.

Companies are increasingly setting ambitious emission reduction targets, aligning their operations with global sustainability goals such as Conference of Parties (COP) standards.

The pressure on energy firms to innovate and create solutions for a future with reduced fossil fuel reliance is mounting.

Small ROVs offer the industry an opportunity to conduct oil and gas extraction more efficiently and with a lower environmental footprint.

By deploying small ROVs for tasks traditionally performed by divers or larger work-class ROVs, the reliance on diesel-burning vessels is lessened and minimises the environmental impact of such operations. Smaller, more agile ROVs can significantly reduce carbon emissions.

|

An ROV undertaking NDT |

We on the service side are committed to reducing our environmental footprint in the design and manufacturing processes of ROVs as well.

Companies are exploring biodegradable and recyclable materials to construct ROV components to ensure minimal environmental impact throughout the ROVs lifecycle.

COMPACT & PORTABLE ROVS

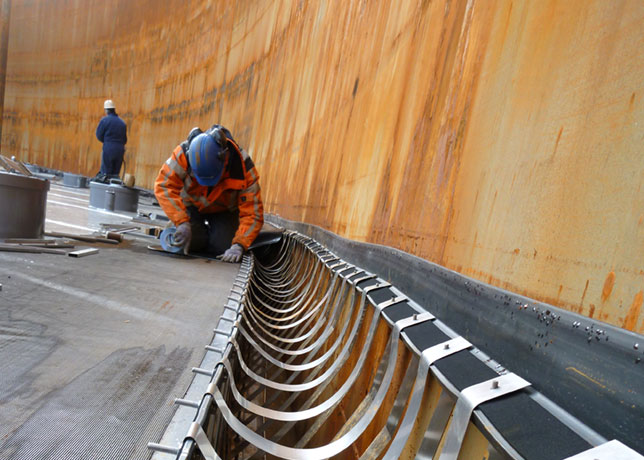

There is a ongoing shortage of work class systems in the oil and gas and renewables markets, so a versatile and easily deployable solution is driving a surge in demand for compact and portable ROVs. These smaller, more nimble vehicles are invaluable in applications, such as weld testing NDT; flooded member detection (acoustic and ultrasonic); ultrasonic thickness gauging; cathodic protection; marine growth removal and jacket structure cleaning; visual inspection (general and close visual inspections); remote crack monitoring sensors; and pipeline inspections.

Smaller machines are now also capable of replacing many tasks traditionally carried out by work class ROV systems, such as drill support; salvage works; pipeline surveys; decom services; and seabed surveys.

These compact ROVs are already revolutionising the industry, significantly altering traditional inspection methodologies.

Due to their small size, compact ROVs facilitate rapid deployment, often directly from offshore platforms or smaller support vessels, eliminating the need for larger, resource-intensive ships.

This reduces logistical complexities and also cuts down on associated emissions and costs. As a result, companies can conduct more regular and detailed inspections without incurring significant additional expenses or environmental impact.

Moreover, the enhanced maneuverability of compact ROVs allows them to access areas that larger vehicles cannot reach.

This capability is particularly beneficial for detailed pipeline inspections and maintenance in complex subsea structures.

Performing high-resolution imaging and precise manipulation in these challenging environments ensures that potential issues are identified and addressed promptly.

The subsea ROV market is witnessing transformative trends driven by advancements in technology and a heightened focus on sustainability.

A GLIMPSE INTO THE FUTURE

So, what will these trends lead to?

In the coming years ROVs will continue to radically change the Energy Industry by becoming smarter, more autonomous, and seamlessly integrated into the broader digital ecosystem of operations.

These advanced underwater machines will no longer merely support subsea tasks; they will drive new efficiencies and capabilities that were previously unattainable and unthinkable.

As mentioned, future ROVs will be equipped with advanced AI-driven analytics and machine learning algorithms, enabling them to learn from each mission and continuously improve their performance.

They will also possess the capability to communicate with other robotic systems and surface vessels, creating a cohesive network that helps to manage and optimise the entire offshore operation.

This network will facilitate real-time data sharing and collaborative problem-solving, ensuring that every aspect of the operation is synchronised.

Moreover, ROVs will play a crucial role in predictive maintenance strategies. By continuously monitoring the condition of underwater infrastructure and utilising sophisticated data analysis, they will be able to foresee potential failures and recommend maintenance actions before issues escalate.

This predictive capability will significantly reduce unexpected downtime and maintenance costs, enhancing overall operational efficiency.

The integration of augmented reality (AR) and virtual reality (VR) technologies will further enhance the utility of ROVs.

Operators will be able to pilot these vehicles with unprecedented precision using immersive AR/VR interfaces, making complex underwater tasks easier and more intuitive. This will not only improve the accuracy of inspections and repairs but also reduce the training time required for new operators.

As the offshore oil and gas industry continues to embrace digital transformation, ROVs will be at the forefront of this evolution. Their ability to operate in harsh environments, combined with their growing intelligence and connectivity, will make them indispensable assets.

* Louis Pietranek is Managing Director of Westerton Access. He was appointed to the company’s Board of Directors in April 2024.

By Abdulaziz Khattak