Francesca Rinaldi

Francesca Rinaldi

FPT Industrial excels in powertrain solutions with a strong focus on sustainability, offering cutting-edge engines, ePowertrain technologies, and natural gas options to meet diverse industrial and environmental needs, Francesca Rinaldi tells OGN

FPT Industrial stands at the forefront of the powertrain industry, spearheading innovation with a comprehensive range of high-performance engines and advanced solutions tailored for diverse applications.

As a leading brand within the Iveco Group, FPT Industrial is committed to delivering exceptional powertrains for on- and off-road vehicles, marine engines, and power generation systems.

In an exclusive interview, Francesca Rinaldi, Product Marketing and Portfolio manager for Power Generation at FPT Industrial, tells OGN energy magazine about the company’s diverse product lineup, which spans from robust diesel engines to pioneering electric and natural gas solutions, and reflects on its dedication to meeting the evolving demands of the global market.

In a rapidly changing energy landscape, FPT Industrial is not only addressing current needs but also anticipating future trends.

Its new ePowertrain plant in Turin exemplifies their commitment to sustainability, being the first carbon-neutral facility within the Iveco Group.

By investing in advanced technologies such as hydrogen, biomethane, and electric drivetrains, FPT Industrial is positioning itself as a key player in the transition to zero-emissions mobility, ensuring they continue to lead in innovation while supporting global green goals.

|

The R24 engine ... specifically designed for emergency and prime power applications |

Below are excerpts from the interview:

Please elaborate on your company’s scope of operations.

FPT Industrial is a world-leading Iveco Group brand specialised in the design, production, and sale of powertrains and solutions for on- and off-road vehicles, as well as marine and power generation applications.

FPT Industrial’s extensive product offering includes six engine ranges with power outputs from 42 hp to over 1,000 hp, transmissions with torque up to 500 Nm, and front and rear axles from 2.45 to 32 tonne Gross Axle Weight.

Sustainability is at the heart of our operations, since we offer the most complete line-up of natural gas engines for industrial applications on the market, with power outputs ranging from 50 to 520 hp, as well as electric drivelines, battery packs, and battery management systems, designed and produced in our dedicated ePowertrain plant in Turin, Italy.

Biomethane, hydrogen, and HVOs are the other energy carriers we are investing in to accelerate the path towards net zero-emissions mobility.

How do you see the region’s energy market evolving in the coming years?

The evolution of the energy market will be driven by three main factors. First, increasing energy demands for daily life, highlighted by the Covid-19 lockdowns, emphasise the importance of energy and connectivity. Second, energy security will become more critical as people seek backup energy during grid disruptions. Lastly, new emissions limits in various regions will impact production strategies. Success will depend on offering differentiated products to meet diverse market needs.

Given the scale of projects under way, what differentiates your company and offerings from competitors in the regional market?

FPT Industrial prioritises customer needs by evaluating power requirements across various sectors and aligning projects with these trends. We offer exceptional flexibility in customising engines for specific uses. Our engines are known globally for their performance, low TCO, reliability, and innovative solutions, such as the Common Rail technology we pioneered in the 1990s.

With sustainability being a key focus, how do your company’s products and services help the region further its green goals?

|

FPT has introduced fully sustainable trade fair stands |

Sustainability is central to our operations. Through our R&D centres, we lead in sustainable propulsion and power solutions. We’re committed to minimising the environmental impact of our products, processes, and even trade fair stands. For instance, starting with Agritechnica 2023, we introduced a fully sustainable stand, designed in collaboration with Polytechnic University of Milan. We analysed its carbon footprint, including transportation and energy use. Materials were transported by IVECO S-Way trucks with FPT Industrial Cursor 13 NG engines, powered by bio-LNG from Shell. We offset residual emissions with certified carbon credits after each exhibition.

What are the biggest opportunities and challenges you see for your company in the market?

The engine market is constantly evolving, every year seeing the entry of new players, often particularly aggressive ones, who "fight" to establish themselves.

For our part, we offer customers not only technological excellence but also and above all proven reliability which is able to make a real difference.

The biggest technological challenges lying ahead of us are the adaptation of our engines to new alternative fuels and future emission limits.

In this regard, I am convinced that governments and international institutions should engage in constant dialogue with engine manufacturers in order to agree on feasible road maps that take into account the state of the art and the needs of customers.

How has business been for your company over the past year? Have there been any significant developments at your company recently?

Over the past year, FPT Industrial has made significant strides with the introduction of the new four-cylinder G-Drive R24 engine. This addition enhances our already extensive engine range for power generation, which spans from 2.4 to 16 litres. The R24 engine is specifically designed for emergency and prime power applications within the 20 to 40 kVA range, offering a compact and efficient solution. It features an integrated engine, radiator, and air filter, which helps minimise its footprint. The R24 is user-friendly with its simple mechanical pump and single-side servicing, making maintenance both straightforward and quick. It is available in both naturally aspirated and turbocharged models, and its ability to switch between 50 Hz and 60 Hz provides flexibility for efficient stock management.

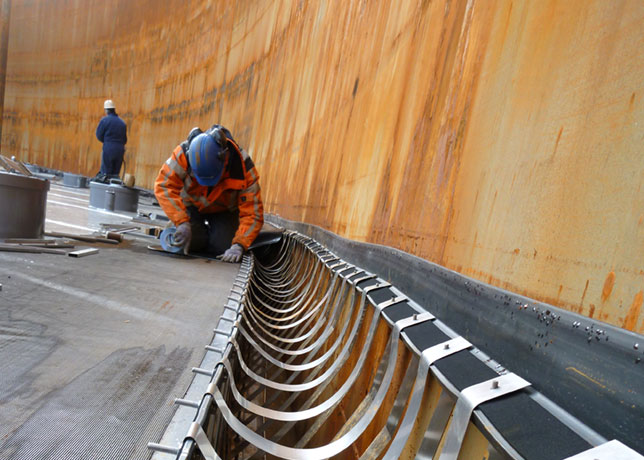

In addition to this product development, a major milestone for us was the opening of our new ePowertrain Plant in Turin in October 2022. This plant is notable as the first carbon-neutral, Industry 4.0 facility within the Iveco Group. It focuses on producing eAxles, batteries, and battery management systems for a range of vehicles, including light commercial vehicles, heavy commercial vehicles, buses, minibuses, and high-performance sports cars. A highlight of this new plant’s output is the Maserati GranTurismo Folgore. This car, equipped with a 100 per cent electric powertrain, boasts cutting-edge 800 V technology and three 300-kW electric motors, delivering over 1,200 hp and marking a significant leap in Maserati’s electrification journey.

What are some of the major orders your company has received in the region?

For us, each and every customer is important and unique. That’s why we proudly serve both large OEMs and regional customers through our extensive global network and thorough customer service. We are always open to welcoming new customers, assessing their present and future needs together in order to deliver genuinely tailor-made solutions.

What are your company's plans for the future - any expansion of production capacity, diversification into new areas, establishment of new offices or plants?

FPT Industrial focuses on two main areas: optimising internal combustion engines (ICEs) and developing future ePowertrain technologies. We continue to invest in diesel, natural gas, and hydrogen fuels to meet current and medium-term needs. Our goal is to provide the best fueling solutions, balancing availability, sustainability, and cost, while improving our engine lineup with state-of-the-art technology.

Our diesel Stage V / Tier 4 Final engines are fully compatible with HVOs without requiring changes to fuel or operation. We also lead in natural gas engines, with products like the N67 engine for tractors, driving a transition to sustainable models. Hydrogen is seen as a promising zero-CO2 solution, though the competition between ICE and fuel cell electric vehicles (FCEVs) remains open.

In the realm of zero-emission solutions, FPT Industrial views electricity as a key alternative energy source. We have proactively developed our own electric powertrain solutions, leveraging our extensive expertise in the field. This approach ensures that we remain at the forefront of technological advancements while meeting evolving market demands.

Anything else you would like to add about your company's activities and products?

As a global leader in industrial powertrains, FPT Industrial serves customers worldwide with a workforce of over 8,000 across 10 production sites and R&D centres. We are committed to providing effective and sustainable solutions for all propulsion and power generation needs. Our renowned customer service includes remanufacturing, technical support, warranty, parts, connected solutions, and serviceability, ensuring maximum uptime and efficient support so our customers can operate with minimal worry.

By Abdulaziz Khattak