Kurt Keam ... committed to KSA growth

Kurt Keam ... committed to KSA growth

The company leverages 17 years of expertise and new technologies to expand its role in Saudi Arabia's energy sector, focusing on local partnerships and sustainable practices for future growth, Kurt Keam tells OGN

Packers Plus is making substantial investments in Saudi Arabia's energy sector, while emphasising localisation and sustainability. The company's innovative technologies and local partnerships are designed to boost efficiency while advancing the Kingdom’s economic and environmental objectives.

In an exclusive interview with OGN energy magazine, Kurt Keam, Middle East Director, Packers Plus, discusses the company's commitment to establishing a standalone presence in the Kingdom, which includes setting up a manufacturing and service centre, a quality control lab, and local R&D capabilities.

Keam highlights how these investments align with Packers Plus' broader goals of strengthening local partnerships and driving growth within the region.

Below are excerpts from the interview:

Packers Plus has been a significant player in Saudi Arabia’s oil and gas completions. How does your experience determine your strategy as you continue to expand resources to support the operations in Saudi Arabia?

Our experience drives our strategy, with our 17 years as a leader in Saudi Arabia's oil and gas completions for the past, particularly in open hole multistage fracturing (OHMSF).

Our extensive experience in this market drives our strategy as we continue to expand our resources to support operations in Saudi Arabia.

We are now strategically entering the liner hanger and sand control markets, leveraging proven technologies and methodologies across our product lines.

Our agility in optimising and enhancing efficiencies in challenging environments will be crucial as we expand our operations in Saudi Arabia.

Can you elaborate on Packers Plus' investment plans for 2024 in the Saudi Arabian energy sector, particularly in partnerships with local entities?

|

The HPHT Titanium XV eliminates full-length cementing |

In 2020, Packers Plus made a significant investment in Saudi Arabia with a promise to establish a standalone presence by 2024.

This commitment includes a fully independent manufacturing and service center, a quality control lab, and in-kingdom research and development capabilities.

In addition to this investment, we are focused on localising our workforce, supply chain, and strategic partnerships to enhance our regional presence and capabilities.

Saudi Vision 2030 emphasises localisation and sustainability in the energy sector. How is Packers Plus aligning its innovations and operations with these goals?

Our efforts are closely aligned with Saudi Arabia's iktva (In-Kingdom Total Value Add) programme and Vision 2030 initiative, reflecting our dedication to supporting the Kingdom’s goals of economic diversification, innovation, and sustainable growth.

We have built a strong foundation for a long-term vision and are committed to serving the Eastern Hemisphere from KSA.

Could you explain how Packers Plus' advanced completion technology, such as the 15K HPHT Open Hole Titanium StackFRAC and 15K TREX Diffusor Cemented systems, addresses the unique challenges of long laterals and high-pressure stimulation in Saudi Arabia?

The Packers Plus 15,000 PSI 400 F, Open Hole Titanium StackFRAC System was introduced to Saudi Arabia in 2017, building on a decade of success with the legacy StackFRAC systems.

This advanced technology addresses the unique challenges of long laterals and high-pressure stimulation by offering several key advantages:

• Elimination of full-length cementing: By removing the need to cement the entire length of the lateral, operational complexity and costs are significantly reduced.

• Precise fracture placement: The system enables precise placement of fractures along the lateral wellbores, optimising stimulation efficiency.

• Isolation of fracturing stages: Utilising RockSEAL II packers and Drillable Closable FracPORTS, each fracturing stage is isolated, ensuring targeted stimulation and preventing communication between zones.

• High flow rate and pressure accommodation: Designed to handle 15,000 PSI and 400F temperatures required for effective fracturing in long laterals, this system also minimises the risk of casing deformation, a common issue in HPHT applications.

The Cemented TREX Diffusor System, introduced in 2022, caters to customers requiring cemented liners for certain wells traditionally completed using the Plug and Perf technique. This system offers:

• Advanced cementing techniques: The use of high-quality materials and sophisticated cementing methods ensures long-term well integrity and reliable operation under extreme pressures typical in HPHT conditions.

• Enhanced well integrity: By providing robust zonal isolation, the system ensures the integrity of the wellbore, crucial for long-term production.

• Access post-fracturing: The system allows for re-entry into the completions after fracturing, facilitating ongoing well management and intervention.

Together, these technologies from Packers Plus provide comprehensive solutions for the challenges of long laterals and high-pressure stimulations in Saudi Arabia, enhancing operational efficiency, well integrity, and overall production performance.

The 15K HPHT Open Hole Titanium StackFRAC and Diffusor Cemented system has been pivotal in enhancing completion efficiency. How do you foresee this technology evolving to meet future demands in the Saudi market?

The 15K HPHT Open Hole Titanium StackFRAC and 15K TREX Diffusor Cemented systems have significantly enhanced completion efficiency.

As we look to the future, Packers Plus is committed to continuous innovation and adaptation to meet evolving demands in the Saudi market.

As reservoir conditions and operational requirements evolve, we will further enhance the capabilities of our systems to deliver even greater efficiency, reliability, and adaptability.

We are dedicated to staying at the forefront of technology design, and our upcoming releases over the next eighteen months will reflect this commitment.

At Packers Plus, innovation is at the heart of what we do. We anticipate that our customers will be highly satisfied with the new technologies we are developing.

By continually pushing the boundaries of what is possible, we aim to provide advanced solutions that address the unique challenges of the Saudi market, ensuring optimal performance and long-term success.

In what ways does Packers Plus promote clean and efficient energy sources through its innovations?

Packers Plus promotes clean and efficient energy sources through its continuous innovations in several impactful ways:

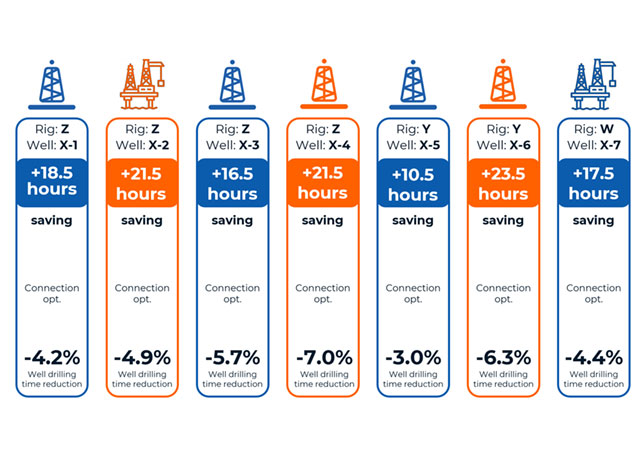

• Enhanced operational efficiency: Our technologies are designed to reduce operational time and improve efficiencies.

By requiring fewer trips in and out of the well, we minimise environmental footprints and reduce surface disturbances associated with multi-stage operations.

• Localised facilities: Establishing localised facilities and manufacturing processes significantly reduces our carbon footprint.

This approach eliminates the need for extensive supply chains from North America, further promoting sustainability.

• Reduced environmental impact: Our innovations focus on delivering solutions that lower material usage and waste, ultimately decreasing the overall environmental impact of our operations.

Through these measures, Packers Plus is committed to advancing clean and efficient energy sources, ensuring that our operations are both environmentally responsible and highly efficient.

Given the complex operational environments in Saudi Arabia, how does Packers Plus ensure the reliability and integrity of its downhole tools, especially in long laterals exceeding 3,000 m?

Packers Plus ensures the reliability and integrity of its downhole tools in complex operational environments in Saudi Arabia, especially in long laterals exceeding 3,000 m with our worldclass R and D teams capabilities, high quality standards such as our API Q1 and Q2 certified QMS standards.

Reliability and Integrity isn't just about meeting industry standards; it's a testament to how Packers Plus delivers quality products and operational excellence from concept to completion.

Could you describe how the collaboration with a major operator in the Middle East influenced the development of the PrimeSET Liner Hanger's anti-preset features, and what specific challenges were addressed during this process?

Our collaboration with a major operator in the Middle East influenced the development of the PrimeSET Liner Hanger's anti-preset features.

The operator had encountered issues with liner top packers from other vendors setting prematurely while being run-in-hole before reaching total depth (TD).

To address this challenge, we developed a solution that isolates hold down slips and elements from any upward force without changing the liner hanger design or operational procedures.

This design eliminated the risk of setting the liner top packer and prevented costly remedial operations. The success of this solution enabled us to scale these features across all our liner hanger product lines with ease of modularity.

With sustainability becoming increasingly important, how does Packers Plus ensure its operations in Saudi Arabia are environmentally responsible and contribute positively to local communities?

Packers Plus is committed to environmental responsibility and positive contributions to local communities in Saudi Arabia.

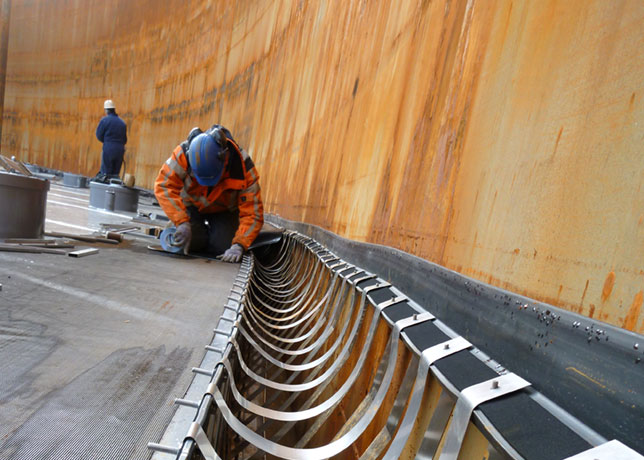

We have embarked on a significant CSR initiative aimed at cleaning up industrial waste and restoring natural landscapes.

Over 2022 and 2023, Packers Plus, in collaboration with Eastern Eamana and supported by various local businesses and educational institutions, spearheaded six cleanup events in the Induscom industrial area adjacent to Mudon Industrial Park 2.

These efforts resulted in the removal of a total of 4500 cu m of waste, setting a new standard in environmental responsibility for the region.

In 2023, the initiative expanded significantly, with participation reaching over 100 volunteers per event.

This growth underscores the community's increasing engagement and commitment to environmental conservation.

Looking ahead, Packers Plus plans to continue these impactful initiatives into late 2024 and 2025, aiming to further enhance environmental awareness and encourage sustainable practices within Saudi Arabia's industrial sectors.

Join us in making a lasting impact on our environment and community let's work together for a cleaner, greener future.

By Abdulaziz Khattak