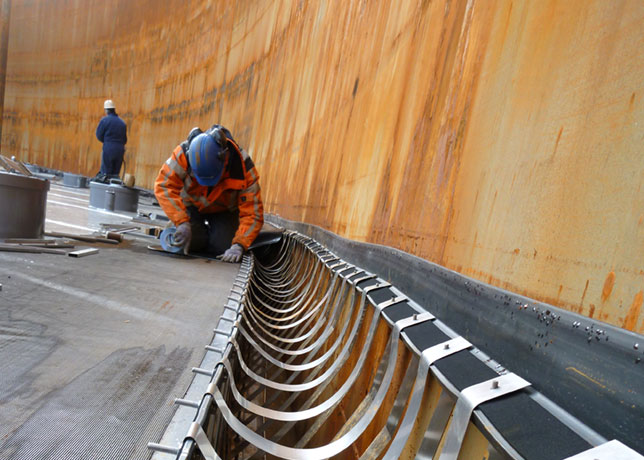

EMC delivers a full spectrum of systems for lifting, pulling, securing, and conveying materials to the offshore industry

EMC delivers a full spectrum of systems for lifting, pulling, securing, and conveying materials to the offshore industry

The company, in partnership with CMCO, offers tailored material handling systems and comprehensive support, ensuring high-quality solutions for industries like automotive and offshore

Eastern Morris Cranes Company (EMC) in Dammam Industrial City has solidified its reputation as a leading provider of integrated material handling solutions.

Established in 2000, the company is known for its commitment to safety and quality, and company delivers a full spectrum of systems for lifting, pulling, securing, and conveying materials, designed to meet the specific demands of industries such as automotive and offshore.

EMC operates under stringent quality control measures, and has been a key player in producing top-tier lifting equipment for over a decade. Continuous research and development ensure its products maintain high reliability and performance.

As a partner of Columbus McKinnon Corporation (CMCO), a global leader headquartered in Charlotte, North Carolina, EMC benefits from a vast international network.

CMCO’s extensive presence spans North America, Latin America, Europe, the Middle East, Africa, Asia, and Oceania, enhancing EMC’s capabilities in delivering superior material handling solutions.

EMC, powered by CMCO, offers a diverse range of products, including STAHL CraneSystems, CM Hoists, Magnetek, and Dorner Conveyors.

The company specialises in creating tailored, complete systems that integrate lifting, pulling, securing, and conveying solutions, ensuring they meet the unique requirements of various sectors.

In addition to its product offerings, EMC provides comprehensive after-sales support through its inspection, spares, and service divisions, reinforcing its commitment to customer satisfaction and operational excellence.

It has the largest crane maintenance service team in the Kingdom with more than 50 employees in 4 service centres across all major cities.

As a manufacturer of EOT cranes, EMC can supply spare part requirements for all major crane brands.

EMC experts conduct regular crane maintenance, offering companies a valuable return on investment as it prevents catastrophic incidents that may result in loss of life, injury and property damage, as well as expensive downtime in production.

By staying ahead of potential issues through a comprehensive preventive maintenance program, the company enhances safety and reliability while ensuring that equipment operates at peak efficiency.

EMC’s proactive approach identifies and addresses wear and tear before it impacts operations, safeguarding assets and supporting continuous, uninterrupted productivity.