An ammonia production workshop at a petrochemical plant

An ammonia production workshop at a petrochemical plant

Decarbonisation and solutions serve as a lever for chemical companies to address existing burdens and bring benefits to the communities in which they operate, says a report by the Renewable Thermal Collaborative

The chemical sector is integral to our daily lives, producing many essential materials, such as fertilisers for our food and the plastics we use every day. It’s also a major contributor to industrial greenhouse gas emissions, responsible for about 20 per cent of the US’ overall industrial emissions.

Taking a deep dive into possible solutions to this challenge, the Renewable Thermal Collaborative (RTC) released the ‘Chemical Sector Decarbonisation Roadmap’ last month, with support from Accenture Development Partnerships.

The report offers a comprehensive analysis of decarbonisation opportunities within the US chemical industry and zooms into the three critical basic chemicals where emissions are most concentrated, laying out a clear and achievable roadmap for each.

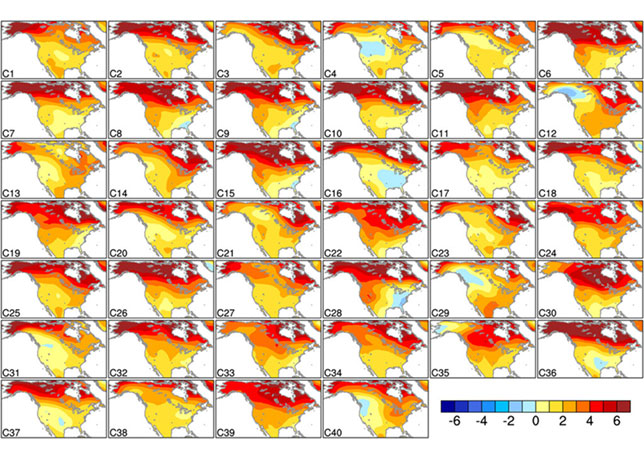

|

Emissions in the chemical sector are concentrated on these three basic chemicals |

If implemented, these strategies which prioritise switching to low-carbon feedstock and deploying renewable thermal solutions could deliver over 60 per cent decarbonisation of the key production processes behind these chemicals alone by 2050.

The biggest takeaway from the assessment, however, is just how achievable it could be to implement these solutions.

When many people think about decarbonising the chemical sector, they may imagine it to be an impossible task.

And while it’s true that this industry has long been considered "hard-to-abate" and the complexity of the processes involved has historically proven a significant challenge, there are readily available technologies and actions companies can take today.

Implementation may not be simple, but the solutions themselves are straightforward especially if chemical companies, downstream corporate consumers, and policymakers act together in pursuing a net-zero pathway.

KEY INSIGHTS

The most emissions-intensive processes for producing the three critical basic chemicals are:

• Steam methane reforming (SMR) and the Haber-Bosch process for producing ammonia primarily used in fertilisers.

• Steam cracking to create the high-value chemicals (HVCs) essential for making plastics.

• SMR for producing methanol, a common chemical for fuel and industrial feedstock. Looking ahead, the demand for products from these three basic chemicals is only expected to grow, highlighting the urgent need to tackle those emission intensive production processes to meet decarbonisation goals.

THE PATH FORWARD

The assessment outlines a two-pronged approach to decarbonise emissions from both fuel and chemical feedstock by prioritising low-carbon feedstocks like clean hydrogen and biobased feedstock and utilising complementary technologies, such as electrification, thermal storage, and carbon capture, utilisation, and storage (CCUS).

Implementing these solutions will not only reduce greenhouse gas emissions, but also offer broader health and economic benefits.

By adopting a low-carbon feedstock and electrifying SMR and steam cracking, chemical companies can enhance health outcomes, spur domestic job growth, and drive the economic revitalisation of surrounding communities.

According to this RTC report, industrial decarbonisation could result in approximately 14,000 fewer premature deaths by 2050, 35 per cent of which would be from disadvantaged communities. This is due to improved air quality from pollution reduction (for example, particulate matter, sulfur dioxide, and nitrogen oxides).

A net-zero pathway in chemicals and refining production could create up to 5.5 million good paying jobs per year while adding about $700 billion to the economy by 2050.

The report also advocates for chemical companies to adopt a "System Value Framework" approach, which actively engages local communities including disadvantaged communities and incorporates community benefits in investment decisions. This approach empowers chemical companies to address existing burdens, like social and environmental impacts of thermal decarbonisations, while delivering tangible benefits to the communities in which they operate, allowing them to accelerate the deployment of decarbonisation solutions and enhancing their social license to operate.

* Co-founded by the World Wildlife Fund (WWF), the Center for Climate and Energy Solutions (C2ES), and David Gardiner and Associates (DGA), the RTC serves as a global coalition for companies, institutions, and governments committed to scaling up the use of renewable heating and cooling to dramatically cut carbon emissions. The coalition is comprised of leading companies, institutions, and governments and collaborates with its Members and Solutions Providers to accelerate industrial decarbonisation by identifying and addressing ways to overcome the technology, policy, and market challenges that large thermal energy users face.

By Abdulaziz Khattak