INTECH's control and safety systems are tested through in-house FATs

INTECH's control and safety systems are tested through in-house FATs

The company pioneers KSA’s industrial future with advanced integration, cybersecurity, and sustainability solutions, aligning with Vision 2030 to enhance local content and drive technological innovation across the Kingdom

As Saudi Arabia advances towards Vision 2030, INTECH is leading the charge in transforming the Kingdom’s industrial sector.

The company is redefining industrial processes through cutting-edge automation, cybersecurity, and sustainability solutions.

In an exclusive interview with OGN energy magazine, a spokesman says INTECH’s role is pivotal in addressing the challenges and opportunities presented by Industry 4.0, ensuring that Saudi Arabia remains at the forefront of global industrial innovation.

INTECH’s strategic investments in expanding its electrical and mechanical infrastructure portfolios reflect its commitment to improving project efficiency and supporting local economic growth.

By enhancing its local content development and aligning with the iktva programme, INTECH is not only contributing to Saudi Arabia’s Vision 2030 goals but also setting new benchmarks for industrial excellence and technological advancement in the region.

Below are excerpts from the interview:

INTECH is primarily known as a US-based system integrator, and has been in the international energy industry for over 30 years. What is the future of system integration for the Saudi Arabian landscape and what role does INTECH see itself playing in that future?

INTECH has been at the forefront of industrial control and system integration for over two generations, evolving from simple punch cards to sophisticated IT/OT integrated networks and remotely operated assets.

|

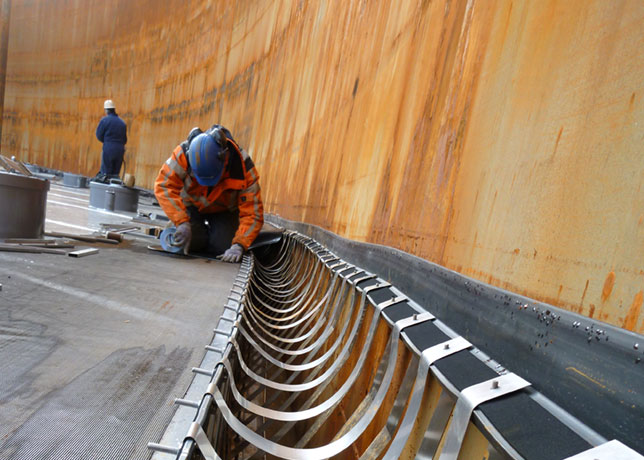

INTECH's single and multi-well WHCPs are robustly built for withstanding extreme offshore and onshore environments |

Our core principle at INTECH is that the pursuit of excellence is perpetual, evolving with technological advancements. Our success hinges on adapting to industrial changes and helping customers embrace new technologies.

We are at a critical juncture with the widespread adoption of Industry 4.0, bringing both opportunities and challenges, particularly in cybersecurity, data intelligence, and user relevance.

In the Saudi industry, multiple factors are making this situation more interesting. These include:

• Expo 2030, offering significant investment and growth opportunities but also bringing economic, political, and security risks.

• The Future Factories programme from the Ministry of Industries and Mineral Resources, aiming to modernise and digitise the Saudi industrial landscape based on the Smart Industries Readiness Index (SIRI).

• The global climate change challenge, demanding strict net-zero Scope 1 and 2 emission targets by 2050.

These challenges also present significant opportunities for leadership and technological innovation.

With the urgent need for solutions focusing on security, efficiency, and modernisation, it is an ideal time for INTECH to thrive as a consultation and integration company in Saudi Arabia.

How is INTECH contributing to the OT cybersecurity landscape in Saudi Arabia? What is INTECH’s approach to securing critical assets without disrupting or affecting OT processes and operations?

|

Remote data acquisition infrastructure from INTECH enables real-time monitoring of distant and remote oilfield |

INTECH’s OT Cybersecurity division features one of the largest in-house teams dedicated to Saudi clients, leading efforts to protect the Kingdom’s vital infrastructure from cyber threats. Our expertise has led to over 150 successful projects.

Our award-winning OTCS team works closely with Saudi cybersecurity partners to deliver customised solutions suited to industrial contexts.

We also focus on developing the skills of the young Saudi workforce in OT Cybersecurity. Our approach involves creating customised frameworks, implementing advanced security technologies, segmenting facility control networks, and establishing zero-trust architectures.

Our non-disruptive project management philosophy includes phased assessments and simulations before deployment to minimise interference with existing OT operations.

We provide 24/7 protection through dedicated SOCs and automated incident response, integrating secure remote access, endpoint protection, and vendor controls to safeguard interactions with OT systems while strengthening OTCS postures.

INTECH recently won awards for Innovation and System Integrator Partner of the Year from Rockwell Automation. How do these accolades reflect on your approach to delivering cutting-edge solutions in automation and cybersecurity?

INTECH’s recognition from Rockwell Automation highlights our long-standing partnership with leading automation system vendors. These awards are part of a broader trend of accolades from major vendors like Honeywell, Siemens, Emerson, ABB, and Schneider Electric.

Our focus on the energy industry has enabled us to build deep expertise in automation and cybersecurity.

Our long-term clients include major national oil companies like Aramco, Adnoc, KOC, and PDO, as well as global oil and gas supermajors like Chevron, Shell, TotalEnergies, and BP.

This experience has reinforced our commitment to adhering to industrial standards and best practices, earning the trust of clients and OEM partners.

INTECH is making significant investments in developing its electrical and mechanical infrastructure portfolios across the Middle East, what implications does this expansion from system integration hold for its position in the industry?

Our expansion into electrical and mechanical infrastructure aims to address inefficiencies and contractual overheads in traditional project approaches.

By managing diverse project scopes in-house, we offer fully integrated solutions, reducing overheads and enhancing efficiency.

We focus on skid-based and portable building solutions, providing mobility, flexibility, and reusability.

We pioneered hybrid e-houses and control buildings integrating electrical and control infrastructure, which have proven successful in brownfield expansions and early production well sites.

Our expertise in Industry 4.0, digitalisation, and cybersecurity has facilitated the modernisation of aging electrical systems.

Additionally, our experience in delivering wellhead control panels and expanding control solutions to include chemical injection, metering, and HIPPS has strengthened our position in surface oil and gas solutions.

How does INTECH contribute to Saudi Vision 2030’s goals, particularly in local content development and advancing iktva objectives?

INTECH’s commitment to Vision 2030 involves investing in local industry by establishing manufacturing capabilities, developing local resources, and participating in energy and infrastructure projects. We align with the iktva programme’s components to enhance our local presence.

We focus on localising automation systems, fabricating control panels, and wellhead control systems.

We employ SIRI-certified digitalisation and cybersecurity consultants in our Saudi workforce, advancing research and development to enhance safety and productivity. Over 20 per cent of our Saudi workforce are nationals, benefiting from extensive training and development.

Our local manufacturing facility in Al-Khobar, set to expand by the end of 2024, will significantly increase our production capacity, supported by a robust local supply chain.

Could you discuss INTECH’s investment plans for 2024 in the Saudi energy sector? How are you partnering with key players to foster clean and efficient energy solutions?

In 2024, INTECH will launch a new 22,000 sq ft manufacturing facility to support clients, improve manufacturing exports, and shorten lead times. This facility will be integral to our global supply chain operations.

Our investments include developing Saudi engineering talent and training our workforce to meet SIRI standards, contributing to the technological advancement of Saudi enterprises.

We will enhance our OT cybersecurity partnerships and develop software solutions to optimise maintenance and supply chains for better facility reliability and readiness.

In what ways does INTECH’s innovation address the evolving challenges in personnel training and promoting sustainability within the energy industry across the GCC?

INTECH’s innovation addresses GCC oil and gas sector challenges through specialised training in industrial automation. We equip personnel with skills in advanced automation technologies, control systems, and process optimisation.

Our training on energy-efficient automation supports compliance with environmental regulations, improving operational efficiency and reducing costs.

Given your extensive experience in the region, how does INTECH ensure the quality and reliability of its wellhead control panels and other automation solutions across geographically diverse locations and extreme production environments?

We ensure quality through robust design, in-house manufacturing, rigorous testing, and multi-stage design approvals.

Our approach includes extensive product inspections and adherence to international standards like ATEX and IECEx.

With over 150 man-years of experience and the trust of leading clients like Aramco, our wellhead control panels are customised for extreme conditions and operational pressures.