The S5000 gas detector is specifically designed to protect workers from hazardous gases

The S5000 gas detector is specifically designed to protect workers from hazardous gases

MSA Safety and Sherbiny’s new local assembly of the General Monitors® S5000 gas detector enhances delivery, support, and safety in the Middle Eastern Oil and Gas sector, aligning with Saudi Arabia’s Vision 2030

MSA Safety, in collaboration with its long-term partner in Saudi Arabia, Mohammed Hassan Sherbiny for Commerce (Sherbiny), has been a key supplier of fixed flame and gas detection products and systems to Saudi Aramco for many years.

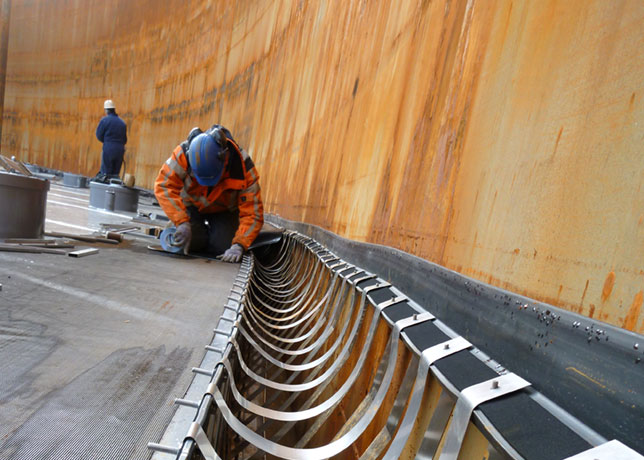

In line with Saudi Arabia’s Vision 2030, Sherbiny has established a new manufacturing division, Atheel, where the General Monitors® S5000 Gas Detector is locally assembled.

This local assembly capability, combined with comprehensive industrial solutions and engineering services provided by Sherbiny, significantly enhances MSA’s ability to serve customers in the region with quicker delivery times and strengthened technical support.

LOCAL MANUFACTURING: A STRATEGIC ADVANTAGE

Local manufacturing through Atheel ensures that the General Monitors® S5000 gas detector can meet the specific demands of the Middle Eastern market efficiently.

By assembling the detectors locally, MSA can quickly respond to customer requirements, drastically reducing lead times and ensuring timely maintenance and support.

|

The General Monitors S5000 gas detector is now locally assembled in KSA |

This local presence not only speeds up delivery but also boosts MSA's capacity to offer tailored engineering and technical services, specifically designed to cater to the unique needs of the region's Oil and Gas sector.

The General Monitors S5000 gas monitor, equipped with advanced XCell® sensors, has garnered significant positive feedback from many leading oil and gas companies in the Middle East.

These organisations have reported substantial improvements in safety and operational efficiency.

The S5000 gas detector is specifically designed to protect workers from hazardous gases such as hydrogen sulfide (H2S CO) and carbon monoxide (CO).

The advanced sensor technology, featuring self-diagnostics and improved performance, helps to lower the total cost of ownership while providing reliable protection.

CUTTING-EDGE SENSOR TECHNOLOGY

MSA’s TruCal® sensor technology offers numerous benefits for users working in hazardous environments. This advanced technology includes:

• Enhanced safety with multiple daily sensor status checks.

• Self-calibrations to adjust for sensor drift caused by environmental changes.

• Extended intervals between manual gas calibrations, up to two years.

• Automatic monitoring for sensor inlet blockages.

• Improved overall performance with better stability and measurement accuracy.

• Longer sensor life thanks to non-consuming ionic electrolyte technology.

• An industry-leading three-year sensor warranty.

• Extended shelf life of up to three years, reducing stocking costs.

Traditionally, gas detectors using electrochemical cells require calibration every 90 days to ensure they can detect target gases and check for blockages. This frequent calibration is necessary because, between these intervals, the sensors might fail to detect gas.

This challenge has historically required labor-intensive and costly servicing. However, MSA’s TruCal technology reduces this burden by performing self-checks four times a day, ensuring real-time accuracy and functionality, thereby minimising the need for frequent manual calibrations.

TruCal technology is integrated into MSA’s patented XCell H2S and CO Electrochemical sensors.

The Pulse Check feature within the sensor provides a reliable method for identifying and correcting changes in output sensitivity (sensor drift). By applying an electronic pulse to the sensor and analyzing the response curve from the last manual gas calibration, MSA’s proprietary algorithms can quantify drift and make real-time accuracy adjustments.

This Adaptive Environmental Compensation (AEC) process occurs every six hours, allowing manual gas calibrations to be extended up to two years.

• Diffusion supervision: Another critical component of TruCal is Diffusion Supervision, an industry-first feature that monitors the sensor’s inlet for blockages.

Traditional sensors can become blocked without the user's knowledge, potentially leading to dangerous undetected gas levels.

Diffusion Supervision continuously checks for blockages, ensuring the sensor's inlet remains clear and functional, enhancing safety and reducing the need for frequent manual calibrations.

• Revolutionary sensor design: The S5000’s Electrochemical sensor features a revolutionary design using a new type of electrolyte that reacts with specific target gases without being consumed.

This innovation extends the sensor life to more than five years, significantly longer than the traditional one to two-year lifespan.

Supported by an industry-leading three-year sensor warranty, this new design help to ensure long-term reliability and reduces maintenance costs.

• Robust and user-friendly transmitter: The S5000 features an enhanced Stainless Steel 316 Transmitter with a touch screen display and LED indicators for easy status monitoring.

The device can be retrofitted quickly and easily, sharing the same mounting footprint as the previous model, the S4000 series.

This compatibility means that upgrades can be done without any hot work, using existing installation accessories and cabling, saving time and resources.

• Advanced connectivity and remote access: The S5000 introduces Bluetooth® communication, allowing users to access the transmitter’s menu through the MSA Connect app.

This feature facilitates faster initial configuration and remote access, especially in hard-to-reach locations.

Various XCell sensors can also be fitted with the new X/S5000 CalGard Remote Calibration Adapter, which allows for remote calibration rather than simple bump tests.

This provides safe and accurate calibrations without having to be at the gas sensor location. This becomes especially important for detectors located in hard accessible locations e.g. in pits or under ceilings.

• Dual sensor capability: The S5000’s dual sensing technology doubles the sensing power while reducing CAPEX costs and installation expenses.

This capability reduces the need for multiple transmitters, as less cabling, cable trays, junction boxes, and other installation accessories are required.

One or both sensors can be remotely mounted up to 100 meters from the transmitter, offering greater flexibility and allowing users to position sensors exactly where they are needed while still easily accessing the transmitter.

The S5000’s gas detector comes with comprehensive safety features. MSA’s TruCal technology ensures that sensors:

• Operate normally within sensitivity limits.

• Compensate for sensitivity drift due to changing environmental conditions.

• Recommend full calibrations when necessary.

• Indicate sensor life status as ‘Good’ or ‘Fair’.

• Check for unblocked sensor inlets.

• Alert users if the device can no longer monitor the area.

CONCLUSION & FUTURE PROSPECTS

By assembling the General Monitors S5000 gas detector locally, Sherbiny and MSA are enhancing the level of safety for workers in the Oil and Gas industry in the Middle East.

The combination of local manufacturing, advanced sensor technology, and positive usage experiences reported by major companies, like Saudi Aramco, underscores the reliability and effectiveness of the S5000 gas detector.

This local approach not only supports Saudi Arabia's Vision 2030 but also ensures that the region's Oil and Gas sector has access to cutting-edge safety solutions tailored to their unique needs.

The local assembly capabilities provided by Sherbiny enhance MSA’s ability to deliver high-quality products quickly and efficiently, strengthening technical support and customer service in the region.

The successful local manufacturing and deployment of the General Monitors S5000 gas detector represent a significant step forward for MSA Safety and Sherbiny in supporting the Kingdom’s Vision 2030.

As more oil and gas companies in the Middle East adopt this advanced technology, the region can expect to see improvements in operational safety and efficiency.

The positive experiences of major players set a precedent for other companies to follow, ensuring that the highest safety standards are maintained across the industry.

With continued innovation and a commitment to local manufacturing, MSA and Sherbiny are well-positioned to lead the way in gas detection technology in the Middle East.

For more on MSA General Monitors® FL5000 MSIR Flame Detector, visit: https://ae.msasafety.com/s5000