Industrial application ... the V-Gard C1 hard hat and V-Flex safety harness

Industrial application ... the V-Gard C1 hard hat and V-Flex safety harness

Enhancing safety in the oil and gas industry requires strategic investments in PPE, hazard detection, and employee training to mitigate risks and improve workplace productivity and safety outcomes, according to MSA Safety

It is hardly necessary to remind anyone that the oil and gas industry is hazardous, but what actions can be taken to address these risks?

MSA Safety emphasises the crucial role that personal protective equipment (PPE) and hazard detection play in mitigating the inherent dangers of this sector.

With the right attitude, careful planning, and informed equipment choices, companies can significantly enhance their efforts to create a safer workplace.

The human tragedy of death at work is brought home powerfully through individual incident descriptions gathered by IOGP (International Association of Oil and Gas Producers).

Published in June 2024, IOGP’s ‘Fatal incident reports’ document covers 26 fatalities worldwide that occurred in 2023.

Of these, seven workers were victims of violent crime rather than industrial accidents. Five others lost their lives during road transport.

While working, four were drowned, three were burned, two were poisoned by gas, two were struck by a moving object, one was crushed, one was electrocuted, and one fell from height.

In some cases, businesses may have a duty to help protect their workers. Many choose to go above and beyond simply complying with the minimum legal standards.

In fact, they view worker safety as a profitable investment, resulting in a more productive workforce, greater operational continuity and less accident-related expense.

TOP HAZARDS

To see where investing in worker safety will count most, we should explore the main risks and challenges.

|

A worker wearing the V-Gard-950 protective cap and holding a ALTAIR-io4 portable gas detector |

The US’ Occupational Safety and Health Administration (OSHA) gives a useful summary of safety hazards associated with oil and gas extraction activities. This includes extensive lists of links to further information in each case.

According to OSHA, three out of every five on-site fatalities result from being struck by, caught in, or caught between something. This could be a falling item, a vehicle, or some other piece of moving equipment.

Blowouts in high-pressure lines are amongst the more specific hazards mentioned by OSHA.

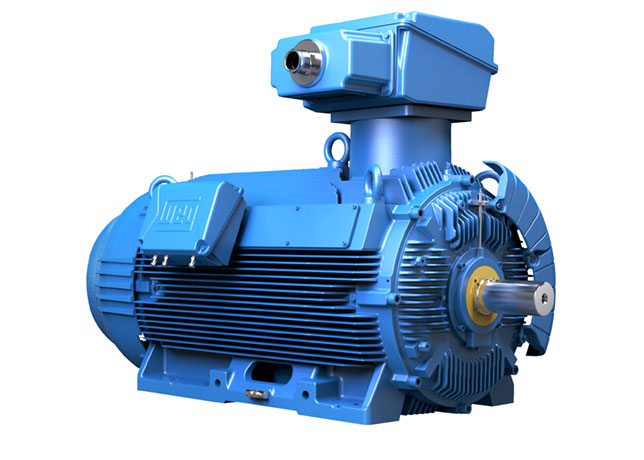

PPE, including protective headgear, footwear and gloves, can be an important line of defence in some of these instances.

A related hazard category is electrical and other hazardous energy, including mechanical and hydraulic.

PPE may be relevant here, too, although procedures such as lockout and tagout may also be used when appropriate to help minimise exposure to these risks.

OSHA also highlights explosion and fire risks due to ignition of volatile and flammable vapours or gases.

Gas and flame detectors can be an important tool to help mitigate or avoid such disasters.

A further threat which we would like to highlight is the toxicity of some gases and chemicals. PPE, such as breathing apparatus, along with portable gas detection equipment, may in certain circumstance help to reduce this threat.

Across industries, falls from height are a leading cause of death. In the UK, for example, falls accounted for 50 out of 138 worker fatalities (36 per cent) in 2023/24.

Fall protection PPE can play a significant role here.

The OSHA hazard summary includes a category on confined spaces, such as storage tanks, pits, pipes and shafts.

Fall protection devices are amongst the PPE used to help keep works safe during confined space entry.

Other hazards in these environments include head bumps, strikes from falling objects, asphyxiation, toxic gases, fires and explosions – each presenting unique considerations for selecting the appropriate PPE.

INVEST IN SAFETY

From the above, one may conclude that there are three key areas in which increased safety investment can have especially strong impacts:

• Gas and flame detectors: Checking for harmful, flammable or explosive gases and vapours is an important first step in workplaces where these hazards are present.

|

Working offshore at height using the V-FIT harness, V-Gard 500 mounted hearing protection |

For the ultimate in productivity and safety, an employer may choose portable, digitalised and connected gas detectors.

These link workers and managers to each other and to a cloud-based software programme, via wireless connectivity.

Their many advantages include prompt device location, quick assignment to users, automatic record-keeping without reliance on the user, and remote monitoring of equipment compliance, condition, and proper use.

The Connected Work Platform driven by ALTAIR io™ 4 Gas Detection Wearable is designed to meet all these needs and more.

Fixed flame detectors can provide another important layer of safety confidence. A difficulty with some flame detectors is their susceptibility to interference from various environmental factors, which can lead to false alarms.

This not only disrupts work but risks desensitising workers to alerts. Today’s most advanced flame detectors use technologies including artificial neural networks (ANNs) to distinguish between real flames and sources of interference.

These technologies, as used in MSA Safety’s latest-generation FL5000 Multi-Spectrum Infrared (MSIR) Flame Detectors, can result in fewer false alarms.

• Headgear: In certain situations, protecting the worker’s vulnerable head and brain is a significant priority. Head protection, such a hard hats, must meet the appropriate legal standards for the specific type of work and environment involved.

When buying head protection or other PPE, you may wish to consider more than just the price.

Higher-quality PPE, while often not the lowest-cost alternative, may well exceed the minimum legal standards, perform better, last longer, require less maintenance, and reduce the whole-life cost of the equipment.

Specific head protection considerations may include choice of non-vented designs for chemical, hot liquid and electric shock hazards, insulated materials for work near electrical equipment, and compact shape for work in confined spaces.

Accessories such as chin straps, liners, eye and face protection, and ear defenders, should be compatible with the selected head protection and should be tested in combination with it.

As with all PPE, comfort and good fit are essential. Uncomfortable, ill-fitting equipment may distract the user, may limit his or her performance, and may be less likely to be consistently worn.

Good suspension, balance and adjustability can be particularly important considerations for head protection.

And don’t forget that the ‘look’ of a hard hat and other PPE may also affect workers’ willingness to wear them. The V-Gard® range of safety helmets is a good place to start your search.

• Fall protection: If collective fall protection, using barriers for instance, is not possible, fall restraint PPE may be the next approach.

This aims to stop a worker from reaching a position where a fall could happen. If this is not feasible, fall arrest PPE may be appropriate to ‘catch’ the worker if he or she falls.

In both cases, this usually entails use of a full-body harness connected via a lifeline – often known as a lanyard – to an anchor point.

Again, equipment should be selected that is appropriate for the specific circumstances.

When choosing any PPE, employers often consult with their workers and take their feelings into account. Issues like ease of use, comfort, fit and styling matter to workers.

Good choices include V-FORM safety harness and V-TEC® Self-Retracting Lifeline (SRL).

Employers often provide training, demonstrations, clear instructions and timely reminders to help reinforce proper use of the equipment. In the case of confined space entry, specific fall protection kits may be appropriate to arrest falls and to rescue fallen or injured colleagues.

A well-established and rehearsed rescue plan can also help increase worker safety.