More complex shapes: Traditional processes such as casting and drilling have reached their limit

More complex shapes: Traditional processes such as casting and drilling have reached their limit

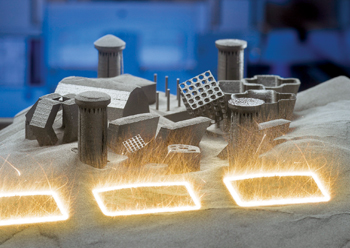

Following the integration of 3D printing as part of its digital services portfolio, Siemens has achieved an industry breakthrough with the first successful commercial installation and continuing safe operation of a 3D-printed part in a nuclear power plant. Because of the stringent safety and reliability requirements in the nuclear sector, achieving this qualification is a significant accomplishment.

The replacement part produced for the Krško nuclear power plant in Slovenia is a metallic, 108mm diameter impeller for a fire protection pump that is in constant rotating operation. The water pump provides pressure for the fire protection system at the plant.

The original impeller was in operation since the plant was commissioned in 1981; its original manufacturer is no longer in business. Obsolete, non-OEM parts are particularly well-suited for this new technology as they and their designs are virtually impossible to obtain. This technology thus allows mature operating plants to continue operating and achieving or, as in the Krško case, even extending, their full life expectancy.

Siemens’ team of experts in Slovenia reverse-engineered and created a "digital twin" of the part. The company’s additive manufacturing (AM) facility in Finspång, Sweden, then applied its advanced AM process using a 3D printer to produce the part.

"We continue to push forward our investments and cutting-edge advancements in additive manufacturing and 3D printing," said Tim Holt, CEO of Siemens Power Generation Services division. "This achievement at the Krško nuclear power plant is another example of how the digital transformation and the data-driven capabilities we have are impacting the energy industry in ways that really matter. Additive manufacturing’s reduced lead times and faster production optimises parts replacement and creates real value for our customers."

Meeting the Krško NPP’s stringent quality and safety assurance requirements required extensive testing that was performed jointly.