The Crane FKX 9000

The Crane FKX 9000

Crane ChemPharma & Energy, a Crane Co business and leading provider of highly engineered fluid handling solutions, has announced its participation in the Offshore Mediterranean Conference & Expo (OMC), March 29-31. (Hall 2, Stand N31 in the Pala De Andre).

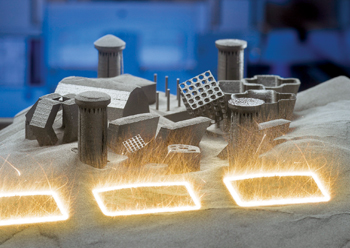

This year, Crane will showcase its latest product introduction, the Crane FKX 9000 Triple Offset Valve.

Engineered to address the inherent dangers of demanding applications, the Crane FKX 9000 adheres to the industry’s most stringent standards, delivering exceptional flow control, optimised Cv and low Delta P, as well as zero-leak shut off in high-temperature applications, hydrocarbon service and emergency shut down (ESD) service.

Featuring an optimised seat angle, metal-to-metal sealing, innovative stem seal and shaft design, and torque seating, this new valve offers numerous cost, safety and performance benefits. Originally available in sizes ranging from 3" to 24", the Crane FKX 9000 will now be available up to 48."

"We are very excited to bring the Crane FKX 9000 to OMC this year, especially with the introduction of the expanded sizes that can prove beneficial to the chemical, power and oil and gas industries," said Ralf Becker, global business line manager – TOV, Crane ChemPharma & Energy. "Crane strives to serve as a dependable business partner to our customers, offering a comprehensive product portfolio of solutions for a wide range of demanding fluid handling applications, and the Crane FKX 9000 is a testament to that mission that we can’t wait to share with the OMC community."

In addition to this new product, Crane ChemPharma & Energy will also display several of its other trusted products, including the Pacific Pressure Seal, Duo-Chek and Noz-Chek energy solutions.

Engineered to provide best-in-class performance to Power and Refining industries worldwide, Pacific® Pressure Seal valves deliver superior solutions in challenging environments. The valve’s self-aligning, spring-loaded discs reduce actuator torque requirements, while positive disc travel stops are cast into the body for uniform seat wear and improved sealing.

With no wedging force, the disc reacts freely to thermal changes, ensuring maximum performance despite changes in temperature.

Duo-Chek wafer valve design is generally stronger, lighter, smaller, and more efficient than conventional swing check valves. To best protect process equipment and deliver the lowest total cost of ownership, the innovative dual-plate design of the Duo-Chek uses springs to increase the valve reaction and response time. This unique design greatly accelerates the valve’s dynamic response time while dramatically reducing the water hammer effect for non-slam performance.