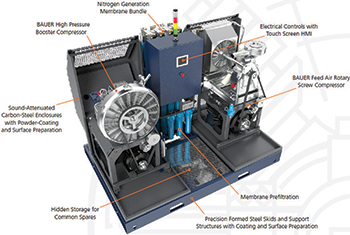

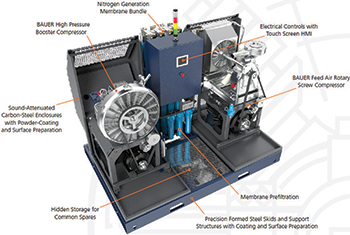

Bauer’s products are cutting-edge

Bauer’s products are cutting-edge

Whilst the recent challenges of the oil and gas sector in the Middle East region has had an impact on the firm’s business, the overall global business was not materially affected thanks to the broad range of industry sectors it serves

Bauer Kompressoren, a leading manufacturer of high pressure compressors and components, has tackled the oil and gas sector downturn during the last three years by refocusing its attention to other market sectors, which have developed favourably.

'With the recent oil price trending upwards, we expect the levels of business in the oil and gas sector to grow steadily this year, which we are confident will deliver a solid growth for us in 2018,' says a company spokesperson.

Bauer had experienced a noticeable upturn in enquiry levels in 2017, which the company is very optimistic will translate into firm orders in 2018.

Year 2017 started slowly as a result of unstable oil prices the previous year. However, with some strategic decisions taken in GCC oil and gas market, business grew well from the second quarter onwards.

'The reason for our success was catering to customer’s requirement instead of focusing on standard equipment. Bauer Kompressoren has always strived for the latest technology which make our products suitable for each generation of operators,' she says.

Bauer’s global business is dominated by European and North American activities geographically, so whilst the recent challenges of the oil and gas sector in the Middle East region has had an impact on the firm’s business, the overall global business was not materially affected thanks to the broad range of industry sectors it serves, and the geographic spread of its customer base.

Bauer Kompressoren GCC is supporting customers in the UAE, Saudi Arabia, Oman, Bahrain, Qatar, Kuwait, Jordan and Lebanon. The major market segments where its compressors were supplied in 2017 were oil and gas (onshore and offshore), government (fire stations at civil defence, police search and rescue) dive-centres, shipping and commercial diving. Compressors are used for producing breathing air, industrial grade air, inert gases and natural gas.

'We supported all these customers not only by selling them compressors but also making sure that there has been after sales support provided by the local distributor in each country. All our distributors are well trained on the product to ensure continuous support,' she says.

TECHNOLOGY TRENDS

The latest product developments are centred round connectivity. 'We now live in a digital and wireless world. In response to this we have introduced new ways to interact with our compressors remotely. One example of this is the B-App which allows owners or operators of our equipment to monitor the performance on their smartphone while sitting at home or even on the beach, in fact wherever there is an internet connection,' she explains.

They can even remotely turn the compressor on and off using the app which is available for IOS or Android devices. Furthermore, with the inclusion of B-Detection built in to Bauer’s latest compressors it is possible to continuously monitor the quality of air being produced. Last year Bauer also introduced Lab on Locale for not only monitoring the air quality continuously but also to provide third-party certification through on line connection with its laboratory in the US.

'We also noticed that the enquiries are generated through EPC contractors who specialise in writing the appropriate specifications for each product,' she says.