John-Bright,-Operations-Director.jpg

John-Bright,-Operations-Director.jpg

Angus Rodger and John Bright tell OGN the energy transition represents a journey and reliable, efficient oil and gas production, supported by service excellence and asset optimisation, will remain core to the region for years

Late last year in a keynote speech at the Abu Dhabi International Petroleum Exhibition and Conference (Adipec), Dr Sultan Al Jaber, Managing Director and Group Chief Executive of the UAE’s Adnoc, referenced how the global economy cannot ‘simply unplug’ from oil and gas as it ramps up a much-needed transition to more renewable energy sources.

Dr Al Jaber forecast hundreds of billions of dollars of investment to keep pace with anticipated demand and the UAE itself has ambitious plans to lift its output capacity to five million barrels per day within 10 years.

Angus Rodger, the General Manager of leading controls technology company Proserv’s Abu Dhabi operation, recognises change is required rapidly but knows this is a journey.

He says: "The need for the world to transition to greener energy sources is irrefutable and Proserv has its own roadmap for pivoting our business, and harnessing our expertise in controls and asset optimisation, into areas such as offshore wind.

|

Rodger ... the need to transition to greener energy is irrefutable |

"But equally, the taps are not suddenly going to be turned off and we will all require hydrocarbons for some years."

He adds: "When you look at the Arabian Gulf, oil and gas have been the cornerstone of economic growth, so we also have a responsibility to support the gradual move to sustainable energy by making sure we can make on-going production efficient to prevent potential leaks and unnecessary emissions, and extend the life of equipment to reduce waste."

BUILDING THE PORTFOLIO

Proserv’s Middle East service business has earned a reputation for its bandwidth of capability (integrating manufacturing via its site in Dubai) and its maintenance agility – what the team calls being ‘OEM agnostic’.

In 2021, Rodger oversaw the acquisition of Dron & Dickson’s Middle East business, providing electrical engineering services and ex-certified equipment, suitable for use in potentially explosive atmospheres.

|

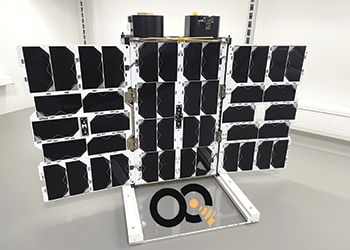

Proserv technicians working on the firm's Smart Box digital solution |

John Bright, Operations Director, who plays a key role liaising and collaborating with Proserv’s major clients, including Adnoc, with whom it enjoys a long-standing partnership, explains the thinking around the deal: "We have always been guided by the voice of our customers and the needs of the market. Over recent years, we have been growing our footprint but our key partners have regularly approached us asking about how we could support them further. So this acquisition was partly instructed by that impetus, and as a result we have expanded our expertise and potential, while reflecting what our clients need."

The Proserv strategy to broaden its service provision is in step with the viewpoint expressed by Adnoc’s top executive at Adipec. With production in the UAE to be increased and sizeable investments to be made, the only way targets will be met is via optimising brownfield assets and this fits into Proserv’s core specialism.

Rodger explains that the addition of the electrical engineering know-how and ability to work in hazardous areas offers advantages throughout the energy value chain.

"We already had a great team of multi-skilled technicians, with broad hydraulics and some electrical capabilities, upgrading and maintaining systems. But the addition of a specialist electrical engineering team, with full Compex certification, means we are more of a ‘one-stop-shop’ service outfit, able to work on a wider array of kit, including in potentially explosive areas.

"The specialist skill set of this team also makes the hazardous areas of our industry safer. From the lighting to wiring and junction boxes, we are upgrading all of this within the production infrastructure so ultimately risks are reduced."

MOVING MIDSTREAM & DOWNSTREAM

Bright describes how the addition of Dron & Dickson’s business is part of Proserv’s natural evolution: "Five years ago, our focus was the wellhead, but we have gradually expanded our abilities ever further. What this acquisition means is that we can now reach into midstream and downstream areas of the industry, such as production facilities and refineries, enhancing the intrinsic electrical reliability and safety during planned shutdowns. This enables us to go to the next level as a service partner."

The certification of the components provided by the new electrical team lends itself to the kind of hazardous zones found within gas processing plants and both Rodger and Bright anticipate more demand from their top-line clients in these areas.

Both also underline that, via this purchase, Proserv has become the principal distributor in the UAE for several globally recognised hazardous area product manufacturers, including Wolf Safety and Weidmüller.

WELL MONITORING TECHNOLOGY

With ambitious production targets mapped out for the UAE, Rodger believes his new electrical team’s expertise will play a core part in upgrading Proserv’s highly effective well monitoring solution – Smart Box.

He emphasises the same rigorous standards around materials and safety certifications, applied to wiring and junction boxes, are being integrated within this accessible and cost-effective device.

Smart Box can make a substantial difference to real-time fault detection, allowing asset managers the ability to be alerted to problems before they occur, simply via an SMS on their cell phone, and able to shut down a well remotely if required.

Rodger stresses the challenges facing the world’s major producers around effective condition monitoring:

"The biggest players can have 5,000 onshore wells, some in inaccessible places, and it is hugely difficult to support the monitoring of these assets. What Smart Box does is provide targeted maintenance interventions if a potential fault is detected, with personnel armed with more information on the nature of the issue, while, with the reassurance offered by the solution’s real-time monitoring, fewer physical visits are then required – saving time and allowing better deployment of resources."

Bright reveals how even a small percentage of outages can impact profitability:

"The NOCs here, Adnoc and Aramco, recognise very well how crucial it is to make sure their towers maintain operations through a joined-up service provision, but any mature asset, producing corrosive fluids for decades, will inevitably develop pain points," he says.

"It is estimated, on average, 2 per cent of wells are out of action at any one time due to various problems. For every million barrels produced, that is 20,000 that could have been but weren’t, and at present prices, that is a seven-figure sum. Downtime quickly mounts up."

ENVIRONMENTAL ANGLE

Bright says Proserv’s Smart Box can be tailored to assess a range of specific parameters that an operator might require and is a perfect monitoring device for remote and ageing wells.

Its simplicity of use means quick decisions can be made and these can have big impacts on both the environment and HSE.

"Around the world, leaks of gases like hydrogen sulphide (H2S) represent a danger to the immediate environment. I know of wells in Europe, close to farmland and residential communities, where this was a major concern. It is an invisible threat to livestock or people that come too close to the leak. Similarly, technicians could approach a well to assess a problem, unaware that H2S is leaking out of it and could be hospitalised, or worse," Bright explains.

"So, in these times where efficiencies need to be improved to reduce emissions and carbon footprints, Smart Box can enable safe, reliable production with an ability to assess potential environmental impacts," he concludes.