The PDG will lower carbon emissions across industrial processes

The PDG will lower carbon emissions across industrial processes

Worley said its pseudo dry gas (PDG) liquid removal system can reduce operational CO2 emissions in gas fields by more than 90 per cent, while increasing technical and commercial viability.

The technology removes the need for topsides and costly compression by reducing back pressure in the pipeline and the shape of the resistance curve. This in turn reduces the associated high carbon emissions and allows for greater tie-back distances.

"As the energy industry strives towards sustainability, it’s important to support solutions that enable decarbonisation," said Andy McDonald, Head of Low Carbon Transition at Scottish Enterprise.

"The pseudo dry gas technology developed by the Worley team in Aberdeen and supported by Scottish Enterprise (with $956,000) will contribute to lower carbon emissions across industrial processes and highlights the innovation taking place across the energy industry in the north east of Scotland."

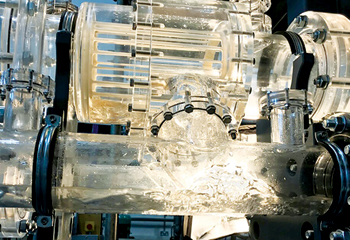

Worley’s pre-production testing will build upon the first prototype. This was created and tested in 2020.

The scope includes the fabrication of a large-scale unit, a magnetic drive subsea pump, and a supporting subsea control system. These are being tested as a system under pressures of more than 130 bar over the expected operational envelope, with a variety of hydrocarbon fluids.

Ahead of this project, Worley conducted several techno-economic concept field studies for various operators.

These studies demonstrated the system’s improved recovery levels compared to competing technology, due to efficiency gains within a tie-back. The studies also showed that upstream CO2 emissions are reduced by the elimination of compression-based systems.

"Driving lower carbon technologies to help our customers is aligned with our purpose of delivering a more sustainable world," said Andrew Berryman, Group President of Technology Solutions.

"It’s significant that PDG has been identified by industry and government bodies as an enabler for emissions reduction and look forward to expanding its use in industry."