Alyousef ... leading Completion Energy

Alyousef ... leading Completion Energy

With in-house engineering, manufacturing and dedicated services to operators, Completion Energy has successfully introduced patented Saudi-designed technology into the international market

Completion Energy, a drilling and completion products manufacturer, has embarked on a manufacturing journey with the aim of becoming one of the first private local companies to support the global oil and gas industry by manufacturing products in Saudi Arabia.

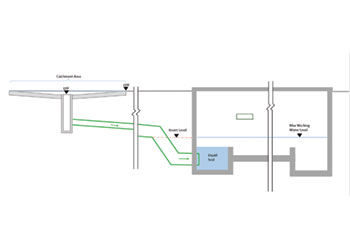

A key component of this strategy is the company’s new factory, which went into operation in Q2 2023. It has a monthly output of over 7,000 products and houses the first 24/7 fully automated machine shop in Saudi Arabia. This is in line with the Kingdom’s Vision 2030.

|

Completion Energy's SolvFrac dissolvable frac plug ... a world first |

"With this facility, we will manufacture products locally and ship them to the US, Canada, Argentina and Russia," says Abdulmuin Alyousef, CEO, Completion Energy.

However, for a global impact, the technology produced must be simultaneously unique and meet Aramco standards.

Completion Energy has thus far been successful in introducing patented Saudi-designed technology into the international market. Its strength lies in the fact that it offers in-house engineering, manufacturing and dedicated services to operators.

"We are the first Saudi company to own patents in well interventions and completions. We already have four in-house technologies patented, and we are in the process of acquiring over 12 more. We are also the first 100 per cent Saudi company to publish two scientific reports in the Society of Petroleum Engineers about our unique technology," says Alyousef.

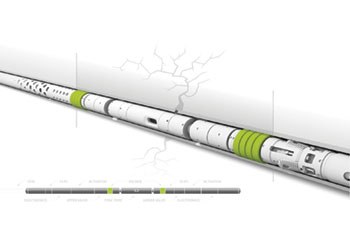

Completion Energy is the main supplier of the dissolvable frac plug, called the SolvFrac plug, and the first company globally with a product like it.

It has supplied a total of 60 plugs to Aramco and the tool has already been run in 21 wells.

Alyousef explains: "Two days after the fracking activity is finished, the frac plug material dissolves and fully disappears."

The main advantage, he says, is that it eliminates the requirement for coiled tubing operations. "It saves time and money. It is also the product of its kind in the market that can hold pressure for 48 hours in a well stimulated with 28 per cent HCl acid, and a maximum bottom hole pressure of 18,148 psi," he adds.

|

Completion Energy's state-of-the-art facility |

Completion Energy has a joint venture with Renegade Wireline Services, one of the largest independent wireline services in the US market, to supply the dissolvable frac plug to the US and Canadian markets.

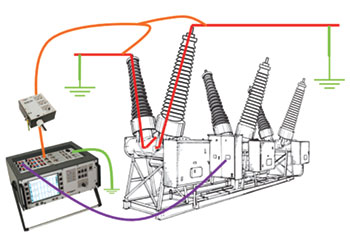

In addition to the frac plug, another of Completion Energy’s flagship products is the high-force extended reach tool, which can help penetrate global markets.

The tool offers a unique solution, as it improves the high frictional forces generated by the flow displacement inside coil tubing in long trajectories, such as in long vertical or horizontal wells.

It generates axial displacement fluctuations and high-flow rates, and can be used in clean-outs or stimulation treatments and high-torque connections that increase strength, which are useful in high-deviated and long-horizontal wells.

Originally designed for Aramco, the high-force extended reach tool has been successfully used in more than 100 projects.

Outside the Kingdom, the US is the biggest market for this type of product.

But reaching this far wasn’t an easy journey for the company, as Alyousef points out.

"Our products received Aramco approval after a lengthy process and this convinced everyone in the market to purchase them, including SLB (formerly Schlumberger), Halliburton, Baker Hughes, Weatherford International, NESR [National Energy Services Reunited] and others. In order to convince end users, we also do aggressive testing according to API requirements," he says.

The company has received government support, and its production costs are currently lower than anywhere in the world, especially with fully automated machine shops.

Outside the Kingdom, Completion Energy already has a presence in Abu Dhabi. This year, it aims to expand its wireline services into the GCC, as a part of its strategy to introduce the dissolvable frac plug in the market.

"Our strategy is to have joint ventures in Qatar, Kuwait, the UAE, Oman, Iraq, Libya and Egypt, among other places. We have two JVs in the process of being set up. Our goal is to take the company public in 2026. So far, the company is employee-owned, meaning that each employee owns a share," says Alyousef.

He adds: "The latest JV, as well as others, will supplement our specialised thru tubing capabilities, allowing us to provide a full package service to our customers, particularly Saudi Aramco under the special LStK type of contract, in which they will only supervise the operations' execution. To achieve this, we must broaden our current capabilities through collaboration with companies that specialise in technologies such as wireline, coil tubing, and snubbing unite services, among others."