Factory testing of liquid hydrogen

Factory testing of liquid hydrogen

The existing international standards are inadequate to fully meet the demands of hydrogen energy applications, with valves facing many challenges, Mason Lu, Neway Valve (Suzhou), tells OGN

As the world’s reserves of fossil fuels continue to dwindle, there is an ever-increasing demand for alternative sources of energy that are sustainable and environment-friendly.

Renewable energy, which includes sources such as wind, solar, biomass, geothermal, and hydrogen, is a non-fossil energy source that plays an essential role in the world’s energy supply system.

Hydrogen energy in particular is emerging as a significant form of renewable energy. However, hydrogen energy presents unique challenges to valve production due to its unconventional working conditions.

The existing international standards are inadequate to fully meet the demands of hydrogen energy applications, with valves facing challenges such as hydrogen corrosion, ultra-low temperatures below -253 deg C, stringent welding performance requirements, and the need for special material control. Failure to address these challenges adequately can lead to valve deformation and pipe explosion, posing serious risks to human safety.

Therefore, it is imperative that we develop internal guidelines, conduct meticulous material selection and testing, in order to ensure the utmost safety of valves.

EXTERNAL AND INTERNAL LEAKAGE RATE CRITERIA

|

Mason Lu ... overcoming challenges |

The ISO 28921-1 standard (Industrial valves, isolating valves, for low temperature applications, design, manufacturing and production testing) is widely apply for cryogenic valve testing but it only covers isolation valves for use in cryogenic temperature service where the design is –50 deg C down to –196 deg C. The valve external leakage for the valve packing and the outside perimeter of the bonnet shall not exceed 1.78 × 10¯6 mbar·l·s–1 per millimeter stem diameter for the packing.

The Specification, SAE-J2579 (Fuel Cell and Other Hydrogen Vehicles) defines design, construction, and operation requirements for hydrogen fuel storage and handling systems in on-road vehicles.

The standard defined the hydrogen system automation valve external leakage should not exceed 2.78x10-4~8.33x10-4 Pa·m3·s-1 and hand operation valve external leakage should not exceed 2.78x10-4 Pa·m3·s-1.

Additionally, No 406/2010-EU (European Parliament and of the Council on type-approval of hydrogen-powered motor vehicles) mentioned seat leakage should not exceed 2.78×10-9 m3·s-1.

So considering above standards and safety, we general prefer level A/B (Approximately 1/3 BS 6364) as acceptance seat leakage class shows in Table 1.

BODY TEST PRESSURE

GTR13: Global technical regulation on hydrogen for fuel cell vehicles mentioned testing acceptance criteria, parties may select to adopt the GTR.

|

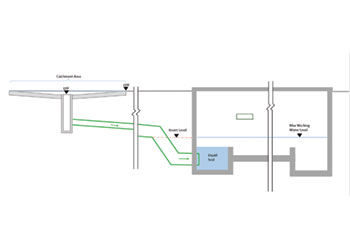

But in GTR, the standard specified maximum initial burst pressure (MIBP), when liquid hydrogen vapourises and expands. The calculation process as follows:

With the additional heat, the volume of liquid hydrogen expands significantly more than what we expect based on our experience with water.

This property is indicated by the coefficient of thermal expansion, which at normal boiling point is 23 times that of water for ambient conditions. The significance for safety arises when cryogenic storage vessels have insufficient open space to accommodate expansion of the liquid. This can lead to an over pressurization of the vessel or entrainment of the liquid into transfer and vent lines.

Above these calculation, shell testing validation shall be able to withstand 4 times the maximum allowable working pressure within 1 min and 2.25 times for below 10Mpa valve.

MATERIAL SELECTION

|

ASME B31.12, which is applicable up to and including the joint connecting the piping to associated pressure vessels and equipment but not to the vessels and equipment themselves.

It provides insights into the interaction between metallic materials and hydrogen, emphasizing the property changes that occur at low temperatures and the potential degradation impact on nonmetallic materials.

Additionally, the ISO/TR 15916 (Basic Considerations for the Safety of Hydrogen Systems) offers a valuable reference in Table C.1, which outlines the hydrogen embrittlement susceptibility of commonly used metals.

This can assist in selecting materials that exhibit slight embrittlement, such as 310, 316, 1020, 1042, among others. However, it is important to note that the applicability of 1020 and 1042 materials may not extend to liquid hydrogen conditions. Therefore, based on these considerations, stainless steel materials appear to be the most cost-effective and suitable choice for hydrogen system applications.

After conducting internal tests on stainless steel (SS) materials with specific content control of Si, Ni, Cr, and P, we have observed an intriguing phenomenon.

When subjected to immersion in both liquid nitrogen and liquid hydrogen, samples made from SS material exhibited minimal dimensional deformation, even when using various sharp sample shapes.

Through rigorous validation and in accordance with the aforementioned standards, we have determined that SS material with content control is the most suitable choice for our application.

The other prefer metal material could follow Table 2.

SUMMARY

|

Dimension comparison in liquid N2/H2 |

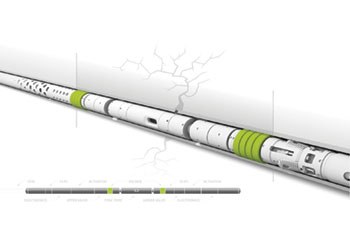

Finally, the design of hydrogen valves extends beyond the aforementioned principles. It encompasses aspects such as the selection of non-metallic materials, calculations for steel wall thickness, stem design, sealing material selection, fire-safe design, cavity over-pressure protection, and the design of body and bonnet extensions for online maintenance. Additionally, it is crucial to degrease, clean, and ensure the dryness of all valves before installation.

As technical engineers, we must consider all potential risks and possibilities.

Thorough prototype testing and validation should be conducted during the planning phase. Hydrogen valves are just one component among numerous hydrogen devices.

We firmly believe that with the collective efforts of individuals in the hydrogen energy industry, the world will witness significant improvements. This industry plays a critical role in protecting the environment, mitigating climate change, and fostering social development.