Mellapak is the most widely used structured packing worldwide

Mellapak is the most widely used structured packing worldwide

Sulzer Chemtech’s separation technology is at the core of successful, value adding carbon capture projects, allowing players in key industries to turn CCUS facilities into profitable plants to generate new revenue streams

Advanced process technologies are key to helping the chemical industry develop and implement successful decarbonisation strategies.

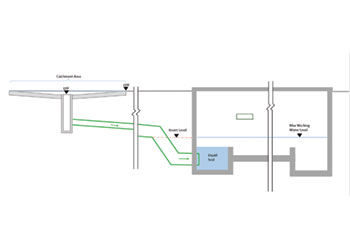

One such technology that Sulzer Chemtech offers is a complete mass transfer solution portfolio that is designed to support highly effective carbon capture, utilisation and storage (CCUS) facilities.

With a proven track record of delivering advanced CCUS solutions on all scales, the leader in separation and mixing technology has developed world-class equipment for such processes.

The ever-expanding range of solutions available is engineered to maximise the removal of carbon dioxide (CO2) from flue gases with high efficiency while preventing the loss or emission of solvents into the atmosphere.

As a result, environmentally oriented players in the CPI can reduce the costs and environmental impact associated with CCUS operations.

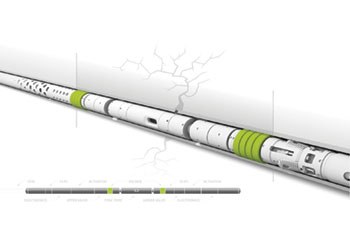

Manufacturers and processors can leverage MellapakCC™ structured packing to set up compact yet highly effective separation units, with achievable capture efficiencies between 90 and 99 per cent.

This column component also significantly reduces pressure drops, optimising the efficiency of amine absorption units.

Thanks to all these features, the annual costs of CCUS operations processing 1,000 tons or more per day of flue gas that leverage MellapakCC™ are expected to be well below EUR45 ($48.88) per ton of CO2 captured.

This CCUS-tailored packing can also be combined with highly efficient MellaTech liquid distributors and AYPlus DC column internals. These help to properly distribute and prevent the loss and emission of amine-based solvents.

As a result, it is possible to optimise solvent utilisation, recovery and ultimately the sustainability of CCUS operations.

Besides, Sulzer Chemtech is helping companies integrate cost-effective excess heat solutions for solvent regeneration to further enhance these benefits.

Thanks to the Sulzer Chemtech’s expertise and state-of-the-art separation technologies, players in key industries have been able to turn CCUS facilities into profitable plants to generate new revenue streams.

Even more, Sulzer Chemtech is helping customers develop innovative carbon utilisation solutions to drive circularity.